- Lean Philosophy

Eight Steps To Practical Problem Solving

The Toyota Way To Problem Solving

The art of problem solving is constantly trying to evolve and be re-branded by folks in various industries. While the new way might very well be an effective method in certain applications. A tried and true way of identifying and solving problems is the eight steps to practical problem solving developed by Toyota, years ago. The system is structured, but simple and practical enough to handle problems of the smallest nature, to the most complex issues.

Using a fundamental and strategic way to solve problems creates consistency within an organization. When you base your results off facts, experience and common sense, the results form in a rational and sustainable way.

The Eight Step Problem Solving Process

- Clarify the Problem

- Breakdown the Problem

- Set the Target

- Analyze the Root Cause

- Develop Countermeasures

- Implement Countermeasures

- Monitor Results and Process

- Standardize and Share Success

The eight steps to practical problem solving also include the Plan, Do, Check and Act (PDCA) cycle. Steps one through five are the planning process. The doing is found in step six. Step seven is the checking . Step eight involves acting out the results of the new standard.

This practical problem solving can be powerful tool to issues facing your organization. It allows organizations to have a common understanding of what defines a problem and what steps are going to be taken in order to overcome the problem efficiently.

The Eight Steps Broken Down:

Step 1: clarify the problem.

A problem can be defined in one of three ways. The first being, anything that is a deviation from the standard. The second could be the gap between the actual condition and the desired condition. With the third being an unfilled customer need.

In order to best clarify the problem, you have to see the problem with your own eyes. This gives you the details and hands-on experience that will allow you to move forward in the process.

Step 2: Breakdown the Problem

Once you’ve seen the problem first hand, you can begin to breakdown the problem into more detailed and specific problems. Remember, as you breakdown your problem you still need to see the smaller, individual problems with your own eyes. This is also a good time to study and analyze the different inputs and outputs of the process so that you can effectively prioritize your efforts. It is much more effective to manage and solve a bunch of micro-problems one at a time, rather than try and tackle a big problem with no direction.

Step 3: Set the Target

Step three is all about commitment and focus. Your attention should now turn towards focusing on what is needed to complete the project and how long it will take to finish. You should set targets that are challenging, but within limits and don’t put a strain on the organization that would hinder the improvement process.

Step 4: Analyze the Root Cause

This is a vital step when problem solving, because it will help you identify the actual factors that caused the issue in the first place. More often than not, there are multiple root causes to analyze. Make sure you are considering all potential root causes and addressing them properly. A proper root cause analysis, again involves you actually going to the cause itself instead of simply relying on reports.

Step 5: Develop Countermeasures

Once you’ve established your root causes, you can use that information to develop the countermeasures needed to remove the root causes. Your team should develop as many countermeasures needed to directly address any and all root causes. Once you’ve developed your countermeasures, you can begin to narrow them down to the most practical and effective based off your target.

Step 6: Implement Countermeasures

Now that you have developed your countermeasures and narrowed them down, it is time to see them through in a timely manner. Communication is extremely important in step six. You’ll want to seek ideas from the team and continue to work back through the PDCA cycle to ensure nothing is being missed along the way. Consider implementing one countermeasure at a time to monitor the effectiveness of each.

You will certainly make mistakes in throughout your problem solving processes, but your persistence is key, especially in step six.

Step 7: Monitor Results and Process

As mistakes happen and countermeasures fail, you need a system in place to review and modify them to get the intended result. You can also determine if the intended outcome was the result of the action of the countermeasure, or was it just a fluke? There is always room for improvement in the problem solving process, but you need to be able to recognize it when it comes to your attention.

Step 8: Standardize and Share Success

Now that you’ve encountered success along your problem solving path, it is time to set the new processes as the new standard within the organization and share them throughout the organization. It is also a good time to reflect on what you’ve learned and address any possible unresolved issues or troubles you have along the way. Ignoring unresolved issues will only lead to more problems down the road.

Finally, because you are a true Lean organization who believes continuous improvement never stops, it is time to tackle the next problem. Start the problem solving process over again and continue to work towards perfection.

Additional Resources

- 8D for Problem Solving – creativesafetysupply.com

- Training to Use 8D Problem-Solving Tactics – blog.creativesafetysupply.com

- The Great Root Cause Problem Solving Debate – realsafety.org

- Design Thinking: Empathy and Iteration for Innovation and Problem-Solving – creativesafetypublishing.com

- 10 Commandments to Continuous Improvement – lean-news.com

- Lean Manufacturing Implementation – The First 5 Steps – iecieeechallenge.org

- No Problem is a Problem – jakegoeslean.com

- The Transitional Steps Involved In The 5s Principles During Implementation – 5snews.com

- The Tools of Kaizen – blog.5stoday.com

Related posts:

- 3P and Lean

- The Vacation Paradox

- Why Single Minute Exchange of Die (SMED)?

- Total Quality Management And Kaizen Principles In Lean Management

- An Engaged Employee is a Productive Employee

- Jim Womack’s Top Misconceptions of the Lean Movement

- Muda, Mura, and Muri: The Three Wastes

University Human Resources

8-step problem solving process, organizational effectiveness.

121 University Services Building, Suite 50 Iowa City , IA 52242-1911 United States

Step 1: Define the Problem

- What is the problem?

- How did you discover the problem?

- When did the problem start and how long has this problem been going on?

- Is there enough data available to contain the problem and prevent it from getting passed to the next process step? If yes, contain the problem.

Step 2: Clarify the Problem

- What data is available or needed to help clarify, or fully understand the problem?

- Is it a top priority to resolve the problem at this point in time?

- Are additional resources required to clarify the problem? If yes, elevate the problem to your leader to help locate the right resources and form a team.

- Consider a Lean Event (Do-it, Burst, RPI, Project).

- ∙Ensure the problem is contained and does not get passed to the next process step.

Step 3: Define the Goals

- What is your end goal or desired future state?

- What will you accomplish if you fix this problem?

- What is the desired timeline for solving this problem?

Step 4: Identify Root Cause of the Problem

- Identify possible causes of the problem.

- Prioritize possible root causes of the problem.

- What information or data is there to validate the root cause?

Step 5: Develop Action Plan

- Generate a list of actions required to address the root cause and prevent problem from getting to others.

- Assign an owner and timeline to each action.

- Status actions to ensure completion.

Step 6: Execute Action Plan

- Implement action plan to address the root cause.

- Verify actions are completed.

Step 7: Evaluate the Results

- Monitor and Collect Data.

- Did you meet your goals defined in step 3? If not, repeat the 8-Step Process.

- Were there any unforeseen consequences?

- If problem is resolved, remove activities that were added previously to contain the problem.

Step 8: Continuously Improve

- Look for additional opportunities to implement solution.

- Ensure problem will not come back and communicate lessons learned.

- If needed, repeat the 8-Step Problem Solving Process to drive further improvements.

8 Steps to Problem Solving: Implement Continuous Improvement in Your Organization

The 8 Steps to Problem Solving Method was developed by Toyota Motor Corporation as a practical, structured, and simple way to handle any problem from the smallest issue to the most complex roadblock.

What is the 8 Step Problem Solving Method?

This problem-solving method helps teams identify and solve problems in a clear and structured way, ensuring that there is consistency within an organization.

This process is an expansion of the Plan, Do, Check, and Act (PDCA) cycle. Steps one through five are part of the planning process, step six is the doing process, step seven is the checking process, and step eight is the acting part of the cycle.

Following this method ensures that your problem-solving technique can be repeated in a sustainable way with the least amount of impact on your customers.

What are the benefits of the 8 Step Method?

There are a few key benefits to using this method to solve your problems:

You get to the root cause of the issue, ensuring the problem is not repeated in the future.

You can better identify and prevent any weak points in your process.

Long-term, effective solutions are generated.

Problems will be reduced over time, increasing your bottom line.

What are the 8 Steps in this Methodology?

Clarify Problem

Break Down Problem

Root Cause Analysis

Develop Countermeasures

See Countermeasures Through

Monitor Results and Processes

Standardize Successful Process

A Detailed look at the 8 Steps to Problem Solving Templates

Step 1: Clarify The Problem

In this step, you need to identify and clarify the problem. Determine why it is a problem, what should be happening instead, and how it fits into the business as a whole.

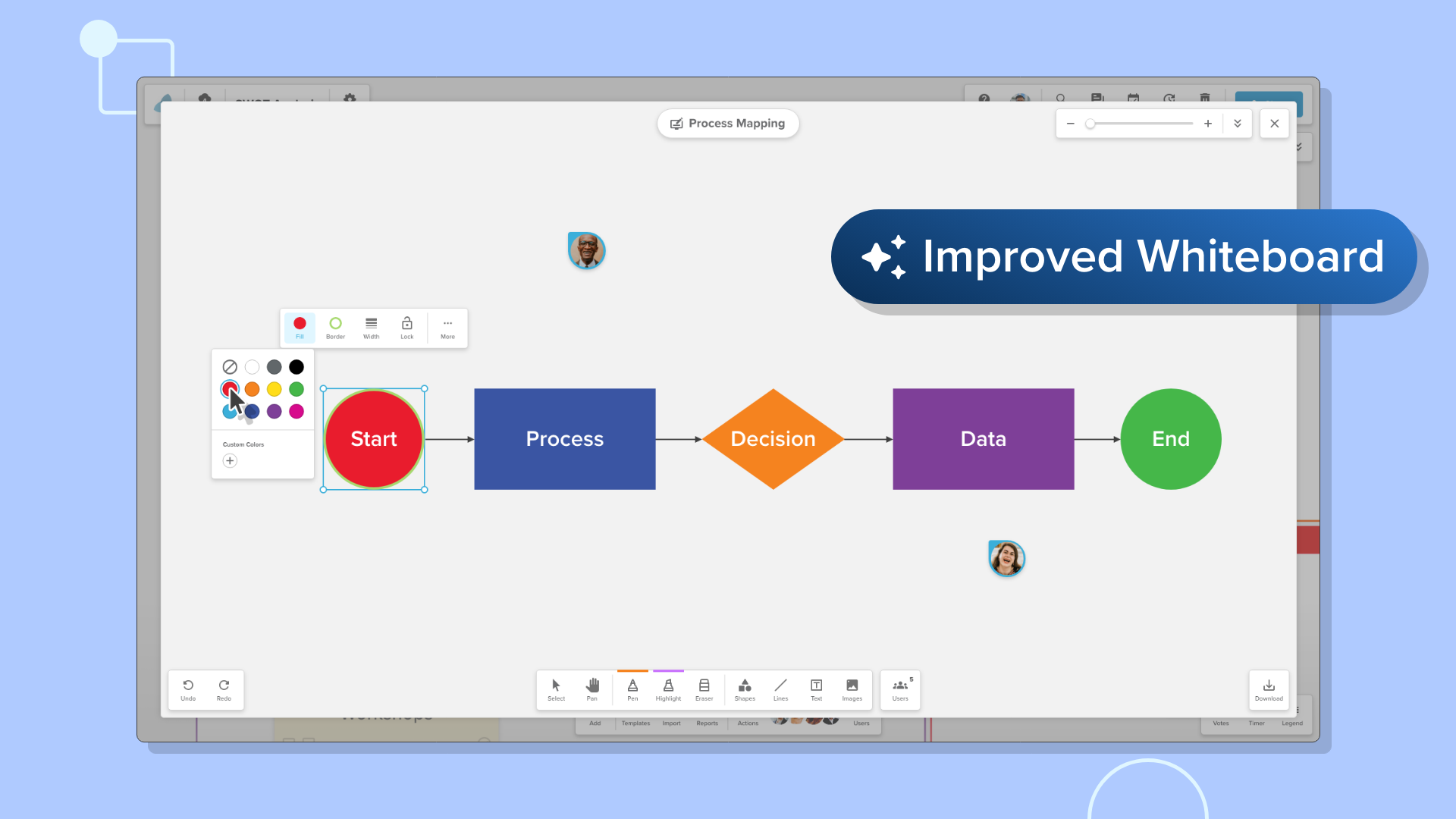

The Stormboard Template for this step is divided into four sections: Clarify Ideal Situation, Clarify Current Situation, Visualize Gap Between Current and Ideal Situations, and Set Ultimate Goal.

Step 2: Break Down The Problem

For this next step, you need to start getting more detailed and specific. Break down the problem into manageable pieces, go see the problem in the process, analyze the issues, and start thinking about priorities.

The Stormboard Template for this step is divided into three sections: Get Your Boots On and Go See, Create a Process Flow, and Identify Point of Occurrence.

Step 3: Set Your Target

This step is where you set clear target dates to resolve the problem. Determine what is needed to reach the target and how long it will take.

The Stormboard Template for this step is divided into three sections: Measurability, Target Point of Occurrence, and What, How Much, and When.

Step 4: Perform a Root Cause Analysis

In this step, you really dig into the factors that are causing the problem. Consider and address all of the causes of the issue — there will usually be more than one.

The Stormboard Template for this step is divided into four sections: Create a Decision-Making Tree, Analyse and Discard Ideas, Ask Why, and Conduct “Why Analysis”.

Step 5: Develop Countermeasures

Use this step to brainstorm countermeasures that will help you remove the root causes of your problem. Come up with as many as possible, and then narrow the criteria matrix and create an implementation plan

The Stormboard Template for this step is divided into three sections: List Root Cause, List Countermeasures, and Chart and Rate Countermeasures.

Step 6: See Countermeasures Through

In this step, you will implement your countermeasures using a clear plan and share the progress of each countermeasure that you implement with your team.

The Stormboard Template for this step is divided into three sections: Implement Countermeasures, Share progress, and Next Steps.

Step 7: Monitor Results and Processes

Use this step to determine if your countermeasures were successful or if they need to be adjusted and reimplemented.

The Stormboard Template for this step is divided into three sections: Evaluate Results, Report, and Lessons Learned.

Step 8: Standardize The Successful Process

In this step, you will integrate your successful countermeasure into your process, share your results with your team, reflect on what you have learned, and make sure there are no unaddressed issues.

The Stormboard Template for this step is divided into three sections: Standardize, Share, and Start a new Kaizen.

See the template →

Are you interested in trying out Stormboard’s 8 Steps to Problem Solving Templates with your team? Sign up for a FREE trial now !

Keep reading.

Learn how DevOps is revolutionizing development and operations workflows, enhancing product delivery speed and cost-efficiency. Explore the critical role of continuous security auditing in DevOps to mitigate vulnerabilities and safeguard against threats.

Project management challenges are inevitable. Here are some common problems and how you can stay ahead of them in 2024.

Explore the transformative landscape of 2023 as Stormboard, riding the generative AI wave, celebrates its most significant year yet. Uncover how Stormboard's core product enhancements and advanced workflow integrations respond to the evolving needs of modern businesses, empowering enterprises to reimagine their technology strategy for a dynamic future.

Unlock innovation and embrace diversity in team brainstorming! Learn strategies to navigate cultural differences and create an inclusive environment for effective ideation while overcoming boundaries and enhancing diversity in collaboration sessions.

Explore Stormboard's Q3 highlights: Discover how user feedback shapes our evolution, and explore Q3 highlights with new features and enhanced UX for global organizations.

Discover how crafting buyer personas can elevate your marketing strategy, making your website more effective and enhancing customer interactions in the competitive business landscape.

Navigate the complexities of business process management (BPM) with a proactive approach to overcome common challenges in implementing automation. Discover how AI technology, no-code, and low-code solutions make BPM accessible, enabling you to streamline processes, cut costs, and save time effectively.

Optimize Collaborative Brainstorming: Learn the art of efficient idea generation with these five crucial steps. Enhance team collaboration, foster innovation, and bid farewell to unproductive meetings. Learn how to elevate your brainstorming sessions for impactful outcomes.

Even with half their waking hours spent at work, professionals experiencing burnout feel time is never enough. Chaotic workdays, heavy workloads, unproductive meetings, and constant distractions are common culprits.

Discover how to reclaim your work-life balance and conquer burnout with these essential time management strategies.

The potential benefits of AI in team collaboration extend far beyond productivity. As we continue to move deeper into the digital era, it’s vital to recognize and utilize AI’s full potential in enhancing teamwork. This article will guide you through the remarkable benefits that AI can bring to the collaborative efforts of your team.

Discover practical strategies for success in the future of work - the hybrid workplace. As a leader of a hybrid team, shape the trajectory of this unique work arrangement by embracing flexibility and technology. Gain insights beyond the typical hybrid work stats and return-to-office trends, and equip yourself with actionable tips to navigate the new work landscape effectively.

How Collaborative Leadership is Changing Business

Scared of the blank page add sample content to your template to get to work faster.

The 8-Step Problem-Solving Method

- November 22, 2021

Table Of Contents

What is the 8-step problem-solving method, the 8 steps and the problem-solving process, the culture of problem-solving.

- Plan, Do, Check, Act (PDCA)

- Gain Problem-Solving Support

As a manufacturing professional, you know how important it is to stay organized, keep your goals in mind and strive for success. But with all of the responsibilities and daily tasks piling up, it takes effort to find and stick to a process that can keep you on track.

Luckily, there’s a tried and trusted way to achieve success in the manufacturing industry.

The eight-step problem-solving process is a structured method that guides you through the various steps of solving issues. Unlike other problem-solving processes that are often broad, the eight-step method takes you through each individual step, from identifying the problem to taking actionable steps to success.

Instead of changing a few things at a middling level that will probably break down again later, you can unearth the roots of problems and build success from the ground up.

For a fundamental breakdown of how to fix problems and lead your manufacturing team to success, here are the eight steps of the problem-solving process.

1. Identify the Problem

The first step in the process is to identify the problem. Identify why this is a problem, how you discovered it and how it impacts your business. Also note when the problem started and how long it has been going on.

If the problem is small, you can try to contain it and may not need additional steps to fix it. However, if the problem is complex, move forward through the process.

2. Define the Problem

The next step involves breaking down the problem and defining what it is. It’s important to be as clear as you can with this step — a vague problem will hinder the process, whereas a clearly defined issue will allow you to take actionable steps to fix it.

Analyze factors like how high of a priority it is to solve the problem. You can also look to data and other resources to clarify or help you understand the concern.

3. Make a Goal

Create an end goal. Envision what fixing this problem would look like and feel like. What would it accomplish? How would it help you? Map out all the ways fixing this problem would benefit you and use it for motivation to achieve your goal. Set a timeline to figure how long it will take to accomplish that goal.

4. Find the Root of the Problem

Often problems are byproducts of deeper, more central problems, so make sure you dig deep enough to find out what is really causing the issue. If the problem is large and complex, break it down into individual parts.

Gather information and use it to identify the deeper issues of the problem and validate what you think the real concern may be. Take time at this step to really focus on the deep problem — executing this step effectively will save you a lot of time down the road.

5. Develop Actionable Steps

Create a list of realistic steps you can take to combat the problem. You can start with a large list and combine or subtract steps, but it’s important you come up with various ways to attack the problem. Use this action plan to draw up a strategy to get at the root of the problem. Each step should be specific and detail-focused — any steps that are vague or tedious will only take up time and cause confusion.

6. Execute Steps

Now that the plan is in place, all you have to do is follow through on your actionable steps. Illustrate the steps you’re taking to your team, explain why you’re taking them and delegate any steps that another employee has to perform to execute your plan.

Communication is key in this step. In most cases, you won’t be executing the plan all by yourself, so make sure you’re expressing the goals and motives of each step with your team so they can see how it connects to the bigger picture.

7. Observe and Evaluate

Monitor your strategy carefully and see how it relates to the original problem. Is it working? Is it only creating more problems? Gather data, talk to your team and be thorough and objective in your evaluation. You might have to readjust your plan as you gain new information, or you may meet your goals and the plan will be successful.

8. Continue the Process

If the plan worked, find ways to continue integrating these steps into your team’s daily routine. If they didn’t work, go back to the goal-setting process or identify some more aspects of the problem — there may be a deeper concern you missed the first time around. Communicate to your team about how the plan went.

In the future, continue using the eight-step process to solve issues and build momentum with your team.

It’s important to build a culture of problem-solving in your manufacturing plant. It can be easy to fall into the trap of “Band-Aid” solutions — quick fixes without digging into the deeper problems.

It’s believed that the eight-step problem-solving process was actually created by the Toyota Motor Corporation to achieve their admired production standards.

From the lore of Toyota, we get some great eight-step problem-solving examples. Taiichi Ohno , the father of the Toyota Production System, observed his workers fixing only the first level of cause when their machines stopped working. To combat this, he developed a problem-solving method to methodically break down each problem of the machine until he found the root cause. Only then could he truly fix the machine.

It’s one of many eight-step problem-solving examples, and it shows the importance of creating a process to increase productivity.

Plan, Do, Check, Act (PDCA) and the 8-Step Problem-Solving Process Differences

The eight-step problem-solving process is an expanded version of the Plan, Do, Check, Act cycle . The first five steps of the 8-step process fall under the planning step, while steps six, seven and eight all correspond to the do, check and act steps. The eight-step process is a more detailed, methodical version of PDCA problem-solving, and converts a vague cycle into something a bit more specific and actionable.

Gain the Problem-Solving Support You Need With MANTEC

MANTEC is the best resource center for manufacturing companies in South Central Pennsylvania. We’re a non-profit that solves any problems a manufacturing facility could have, including sales and marketing , process improvement , manufacturing technology and workforce engagement .

Our expert staff has had vast experience in the manufacturing industry, and we can provide the guidance you need to get your business running at top efficiency. Our services are affordable and extremely valuable. Contact us today!

Related Posts

Understanding market trends and consumer behaviors become more critical as the world becomes increasingly digitized.…

Benefits of Six Sigma Certification

Six Sigma Belt Training in PA Yellow Belt Training Green Belt Training Black Belt Training

.css-s5s6ko{margin-right:42px;color:#F5F4F3;}@media (max-width: 1120px){.css-s5s6ko{margin-right:12px;}} Join us: Learn how to build a trusted AI strategy to support your company's intelligent transformation, featuring Forrester .css-1ixh9fn{display:inline-block;}@media (max-width: 480px){.css-1ixh9fn{display:block;margin-top:12px;}} .css-1uaoevr-heading-6{font-size:14px;line-height:24px;font-weight:500;-webkit-text-decoration:underline;text-decoration:underline;color:#F5F4F3;}.css-1uaoevr-heading-6:hover{color:#F5F4F3;} .css-ora5nu-heading-6{display:-webkit-box;display:-webkit-flex;display:-ms-flexbox;display:flex;-webkit-align-items:center;-webkit-box-align:center;-ms-flex-align:center;align-items:center;-webkit-box-pack:start;-ms-flex-pack:start;-webkit-justify-content:flex-start;justify-content:flex-start;color:#0D0E10;-webkit-transition:all 0.3s;transition:all 0.3s;position:relative;font-size:16px;line-height:28px;padding:0;font-size:14px;line-height:24px;font-weight:500;-webkit-text-decoration:underline;text-decoration:underline;color:#F5F4F3;}.css-ora5nu-heading-6:hover{border-bottom:0;color:#CD4848;}.css-ora5nu-heading-6:hover path{fill:#CD4848;}.css-ora5nu-heading-6:hover div{border-color:#CD4848;}.css-ora5nu-heading-6:hover div:before{border-left-color:#CD4848;}.css-ora5nu-heading-6:active{border-bottom:0;background-color:#EBE8E8;color:#0D0E10;}.css-ora5nu-heading-6:active path{fill:#0D0E10;}.css-ora5nu-heading-6:active div{border-color:#0D0E10;}.css-ora5nu-heading-6:active div:before{border-left-color:#0D0E10;}.css-ora5nu-heading-6:hover{color:#F5F4F3;} Register now .css-1k6cidy{width:11px;height:11px;margin-left:8px;}.css-1k6cidy path{fill:currentColor;}

- Business strategy |

- Problem management: 8 steps to better p ...

Problem management: 8 steps to better problem solving

Problem management is an 8 step framework most commonly used by IT teams. You can use problem management to solve for repeating major incidents. By organizing and structuring your problem solving, you can more effectively get to the root cause of high-impact problems—and devise a solution. Solving the root cause prevents recurrence and creates a repeatable solution to use on similar errors in the future.

In an IT department, errors and mishaps are part of the job. You can't always control these problems, but you can control how you respond to them with problem management. Problem management helps you solve larger problems and reduce the risk that they’ll happen again by identifying all connected problems, solving them, and planning for the future.

What is problem management?

Problem management is an 8 step framework most commonly used by IT teams. Your team can use problem management to solve for repeating major incidents. By organizing and structuring your problem solving, you can more effectively get to the root cause of high-impact problems—and devise a solution. Problem management is a process—used mostly by IT teams—to identify, react, and respond to issues. It’s not for every problem, but it’s a useful response when multiple major incidents occur that cause large work interruptions. Unlike problem solving, problem management goes beyond the initial incident to discover and dissect the root causes, preventing future incidents with permanent solutions.

The goals of problem management are to:

Prevent problems before they start.

Solve for repetitive errors.

Lessen each incident’s impact.

Problem management vs. incident management

Example: Someone leaves their unprotected laptop in a coffee shop, causing a security breach. The security team can use incident management to solve for this one, isolated event. In this case, the team could manually shut down the accounts connected to that laptop. If this continues to happen, IT would use problem management to solve the root of this issue—perhaps installing more security features on each company laptop so that if employees lose them, no one else can access the information.

Problem management vs. problem solving

While similar in name, problem management differs slightly from problem-solving. Problem management focuses on every aspect of the incident—identifying the root cause of the problem, solving it, and prevention. Problem solving is, as the name implies, focused solely on the solution step.

Example: You’re launching a new password management system when it crashes—again. You don’t know if anything leaked, but you know it could contain confidential information. Plus, it’s happened before. You start the problem management process to ensure it doesn’t happen again. In that process, you’ll use problem solving as a step to fix the issue. In this case, perhaps securing confidential information before you try to launch a new software.

Problem management vs. change management

Change management targets large transitions within your workplace, good and bad. These inevitable changes aren’t always negative, so you can’t always apply problem management as a solution. That’s where change management comes in—a framework that helps you adjust to any new scenario.

Example: Your company is transitioning to a new cloud platform. The transition happens incident-free—meaning you won’t need problem management—but you can ease the transition by implementing some change management best practices. Preparing and training team members in the new software is a good place to start.

Problem management vs. project management

Project management is the framework for larger collections of work. It’s the overarching method for how you work on any project, hit goals, and get results. You can use project management to help you with problem management, but they are not the same thing. Problem management and project management work together to solve issues as part of your problem management process.

Example: During problem management, you uncover a backend security issue that needs to be addressed—employees are using storage software with outdated security measures. To solve this, you create a project and outline the tasks from start to finish. In this case, you might need to alert senior executives, get approval to remove the software, and alert employees. You create a project schedule with a defined timeline and assign the tasks to relevant teams. In this process, you identified a desired outcome—remove the unsafe software—and solved it. That’s project management.

The 8 steps of problem management

It’s easy to get upset when problems occur. In fact, it’s totally normal. But an emotional response is not always the best response when faced with new incidents. Having a reliable system—such as problem management—removes the temptation to respond emotionally. Proactive project management gives your team a framework for problem solving. It’s an iterative process —the more you use it, the more likely you are to have fewer problems, faster response times, and better outputs.

1. Identify the problem

During problem identification, you’re looking at the present—what’s happening right now? Here, you’ll define what the incident is and its scale. Is this a small, quick-fix, or a full overhaul? Consider using problem framing to define, prioritize, and understand the obstacles involved with these more complex problems.

2. Diagnose the cause

Use problem analysis or root cause analysis to strategically look at the cause of a problem. Follow the trail of issues all the way back to its beginnings.

To diagnose the underlying cause, you’ll want to answer:

What factors or conditions led to the incident?

Do you see related incidents? Could those be coming from the same source?

Did someone miss a step? Are processes responsible for this problem?

3. Organize and prioritize

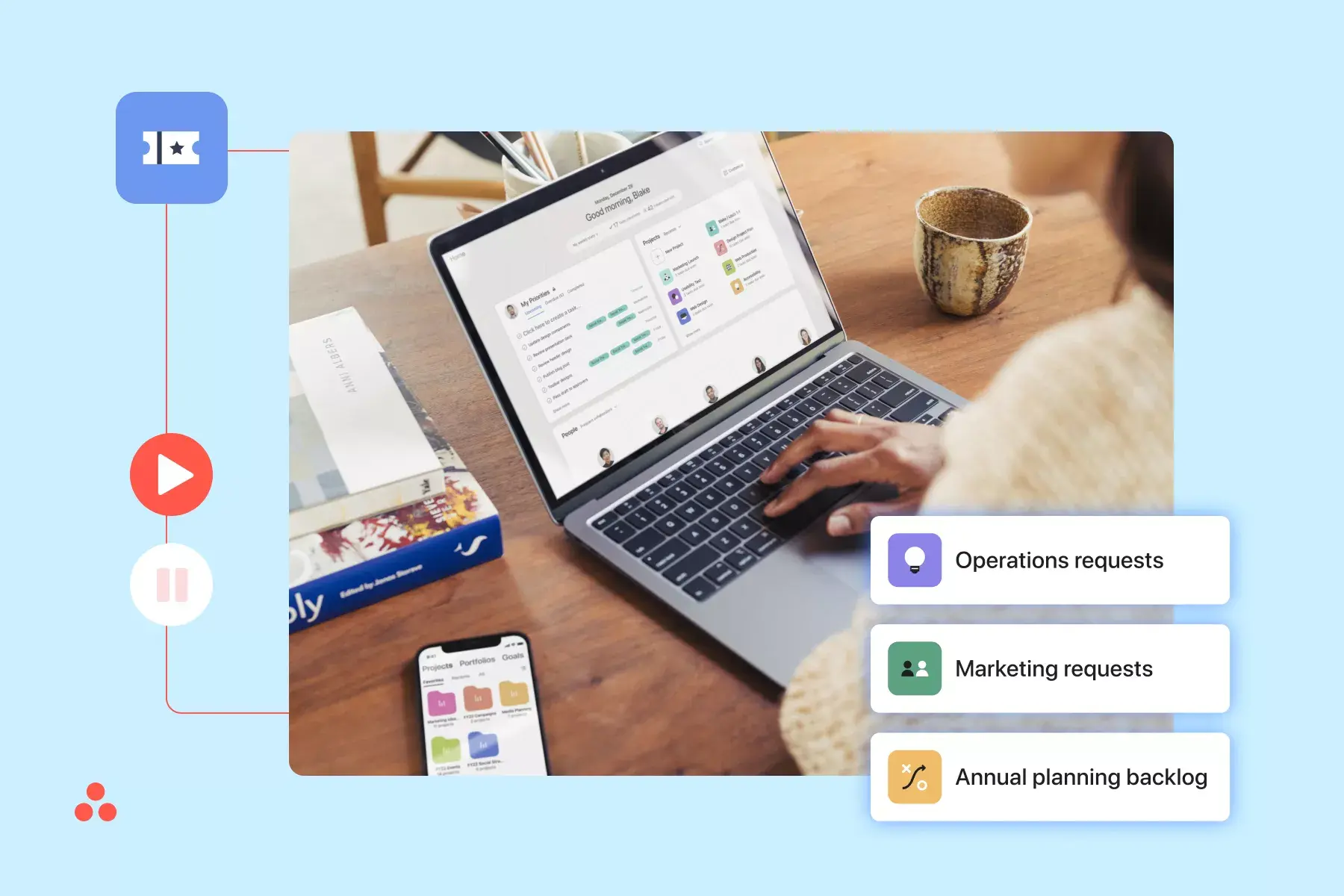

Now it’s time to build out your framework. Use an IT project plan to organize information in a space where everyone can make and see updates in real time. The easiest way to do this is with a project management tool where you can input tasks, assign deadlines, and add dependencies to ensure nothing gets missed. To better organize your process, define:

What needs to be done?

Who’s responsible for each aspect? If no one is, can we assign someone?

When does each piece need to be completed?

What is the final number of incidents related to this problem?

Are any of these tasks dependent on another one? Do you need to set up dependencies ?

What are your highest priorities? How do they affect our larger business goals ?

How should you plan for this in the future?

4. Create a workaround

If the incident has stopped work or altered it, you might need to create a workaround. This is not always necessary, but temporary workarounds can keep work on track and avoid backlog while you go through the problem management steps. When these workarounds are especially effective, you can make them permanent processes.

5. Update your known error database

Every time an incident occurs, create a known error record and add it to your known error database (KEDB). Recording incidents helps you catch recurrences and logs the solution, so you know how to solve similar errors in the future.

![8 steps in problem solving [product ui] Incident log example (lists)](https://assets.asana.biz/transform/4656a136-713e-4caf-8fa1-9556a8bb666e/inline-project-management-incident-management-3-2x?io=transform:fill,width:2560&format=webp)

6. Pause for change management (if necessary)

Larger, high-impact problems might require change management. For example, if you realize the problem’s root cause is a lack of staff, you might dedicate team members to help. You can use change management to help them transition their responsibilities, see how these new roles fit in with the entire team, and determine how they will collaborate moving forward.

7. Solve the problem

This is the fun part—you get to resolve problems. At this stage, you should know exactly what you’re dealing with and the steps you need to take. But remember—with problem management, it’s not enough to solve the current problem. You’ll want to take any steps to prevent this from happening again in the future. That could mean hiring a new role to cover gaps in workflows , investing in new softwares and tools, or training staff on best practices to prevent these types of incidents.

Read: Turn your team into skilled problem solvers with these problem-solving strategies

8. Reflect on the process

The problem management process has the added benefit of recording the process in its entirety, so you can review it in the future. Once you’ve solved the problem, take the time to review each step and reflect on the lessons learned during this process. Make note of who was involved, what you needed, and any opportunities to improve your response to the next incident. After you go through the problem management process a few times and understand the basic steps, stakeholders, workload, and resources you need, create a template to make the kickoff process easier in the future.

5 benefits of problem management

Problem management helps you discover every piece of the problem—from the current scenario down to its root cause. Not only does this have an immediate positive impact on the current issue at hand, it also promotes collaboration and helps to build a better product overall.

Here are five other ways problem management can benefit your team:

Avoids repeat incidents. When you manage the entire incident from start to finish, you will address the foundational problems that caused it. This leads to fewer repeat incidents.

Boosts cross-functional collaboration. Problem management is a collaborative process. One incident might require collaboration from IT, the security team, and legal. Depending on the level of the problem, it might trickle all the way back down to the product or service team, where core changes need to be made.

Creates a better user experience. It’s simple—the fewer incidents you have, the better your customer’s experience will be. Reducing incidents means fewer delays, downtime, and frustrations for your users, and a higher rate of customer satisfaction.

Improves response time. As you develop a flow and framework with a project management process, you’ll be better equipped to handle future incidents—even if they’re different scenarios.

Organizes problem solving. Problem management provides a structured, thoughtful approach to solving problems. This reduces impulsive responses and helps you keep a better problem record of incidents and solutions.

Problem management leads to better, faster solutions

IT teams will always have to deal with incidents, but they don’t have to be bogged down by them. That’s because problem management works. Whether you employ a full problem management team or choose to apply these practices to your current IT infrastructure, problem management—especially when combined with a project management tool—saves you time and effort down the road.

With IT project plans, we’ve made it easier than ever to track your problem management work in a shared tool. Try our free IT project template to see your work come together, effortlessly.

Related resources

Unmanaged business goals don’t work. Here’s what does.

How Asana uses work management to effectively manage goals

Beat thrash for good: 4 organizational planning challenges and solutions

How Asana uses work management to streamline project intake processes

- Guide: 8D Problem Solving

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: June 13, 2023

- Learn Lean Sigma

8D Problem Solving is a systematic and structured approach used to solve business related problems. It names has been given by the fact there are 8 steps or 8 disciplines that are followed to identify, correct and eliminate recurring problems.

8D Problem Solving is regarded as robust methodology that has proven its worth across multiple industries and manufacturing in particular. The methodology was Initially developed within the automotive industry, it has since been widely adopted in manufacturing, logistics and health care to name a few. The 8D approach goes beyond helping team just identify the root cause of problem but also provides a structured approach for implementing and verifying corrective actions.

Table of Contents

What is 8d problem solving.

The 8D Problem-Solving methodology was developed in the late 1980s by Ford Motor Company. The term “8D” stands for “Eight Disciplines,” which represent the eight critical steps in problem-solving.

Initially it was only intended to resolve issues within the automotive manufacturing process. However, over the year since then the methodology has gained universal acceptance and is now applied across various sectors. The 8D approach was heavily influenced by quality management systems like Total Quality Management (TQM) and methodologies like Six Sigma and forms a key part of quality roles and Six sigma qualifications.

8D is also encourages collaborative team based approach to addressing issues in the workplace This methodology was purposefully designed to be a cross-functional effort, ensuring to bring together expertise from different departments or disciplines to comprehensively address an issue by looking at it from all point of view. Here are the key components:

Preparation : Before diving into problem-solving, the team gathers all necessary resources and tools.

Team Establishment : A cross-functional team is assembled, each member having a specific role and responsibility.

Problem Description : The issue at hand is clearly defined to ensure everyone has a shared understanding.

Interim Actions : Short-term solutions are implemented to contain the problem and prevent further damage.

Root Cause Analysis : Various tools and methods are used to identify the real cause of the problem.

Permanent Corrective Actions : Long-term solutions are selected and verified to eliminate the root cause.

Implementation : The long-term solutions are implemented across the board, including necessary changes to policies and procedures.

Prevent Recurrence : Measures are taken to ensure that the problem does not occur again.

Team Recognition : The team is congratulated and acknowledged for their efforts.

How does 8D Compare to over Problem-Solving Methods?

Between quality management systems and lean six sigma there are several problem-solving methodologies such as PDCA (Plan-Do-Check-Act), DMAIC (Define-Measure-Analyze-Improve-Control), and A3 . However the combination of the 8D steps results in a comprehensive frame work that is:

Team-Oriented : Unlike some methodologies that can be carried out by individuals, 8D strongly emphasizes team collaboration as a core principle as seen in steps D1 and D8.

Structured Framework : 8D provides a very detailed, step-by-step guide for solving complex problems, by breaking it down in to logical steps making it easier to manage and track progress.

Broad Applicability : While some methodologies like DMAIC are closely tied to Six Sigma, 8D can be applied in various contexts without being tied to a particular quality management system.

Focus on Prevention : 8D not only aims to solve the problem but also focuses on implementing changes to prevent its recurrence, making it a complete approach to problem solving.

The 8 Disciplines Explained

D0: prepare for the process.

Before you start 8D you should prepare for the 8D process. This phase sets the foundation for the entire methodology, ensuring that the team is able to tackle the problem effectively. Therefore, effective preparation helps in avoiding unnecessary delays and ensures that you’re not solving the wrong problem.

Within the initial preparation step you should also the time to think about what knowledge, expertise and experience you need within the team. Cross-functional teams are important, as they bring alternative perspectives and skills to the table rather than everyone looking at the problem from one point of view. Make sure you consider expertise, availability, and interest when selecting team members.

D1: Establish the Team

In D1 you should establish the team by clearly defining the roles and responsibilities for each team member. This includes assigning a team leader, subject matter experts, and roles for data collection , analysis, and communication this helps to provide the team members clarity on how they will be involved and contribute to the success of the problems solving activity.

Team Composition

Once roles are defined, where possible ensure that the team is balanced in terms of skills and expertise. A well-rounded team will be more effective in tackling various aspects of the problem.

Communication

Establish clear methods communication, both within the team and with external stakeholders. Such as deciding on regular meeting schedules that everyone can attend, reporting formats, and tools for collaboration.

D2: Describe the Problem

In D2 it is time to create a well formed problem statement. This step is key as it provides a foundation for understanding the problem which will lead to generally more successful problem-solving. It ensures that everyone clearly understands what needs to be addressed, setting the scope for the entire process. Ensure that the problem is clearly understood by everyone in the team at this stage to prevent confusion later on in the process.

5W1H Method of creating a Problem Definition

Use data gathering techniques such as observations, interviews, and document reviews can help to precisely identify the problem. A useful tool to use at this stage could be the 5W1H Problem definition method.

You can find out more about this method with our 5W1H guide .

Problem Definition – is / is not template

When creating your problem definition ensure to be specific, measurable, and unambiguous when stating the problem. You should avoid generalities and ensure that the problem statement is understandable to someone unfamiliar with the issue. If you are new to this process it may be helpful to give the statement to someone unfamiliar to the process and see if they understand it or if they have questions. You can then clarify any questions by adjusting the problem description to improve the claity.

D3: Implement and Verify Interim Actions

In D3 while the team is investigating the root cause, interim actions are must be implement to contain the problem and minimize its impact. This is particularly important in critical situations affecting safety, compliance, or customer satisfaction.

In this step you should identify, plan, and execute short-term fixes that can quickly contain the problem. This could include quarantining the product to ensure it is not sent out to the customer or even pausing production lines that continue to product defects. Ensure these actions are documented for future reference.

Use metrics and KPIs to gauge the effectiveness of the interim actions. Make adjustments as necessary.

D4: Root Cause Analysis

D4 is where you start to understand what is causing the issue by identifying the underlying reason for the problem. The objective is to find the root cause, not just the symptoms.

At this stage there are a range of quality and lean six sigma tools that can be used to conduct root cause analysis , which can include the Fishbone Diagram for structured brainstorming and the 5 Whys technique for causal chain analysis.

We have a range of guides on all of these techniques for you to use.

Once identified, it is important validate the root cause through experimentation or additional data analysis to ensure it’s the actual cause and not a symptom, this can often be an overlook critical step in the root cause process.

D5: Choose and Verify Permanent Corrective Actions

In D5 you need to choose what actions to be taken to prevent the problem reoccurring and any solutions implemented should be verified that the actions correct the problem this can involve trial runs, further data collection and inspections of product or services being produced.

You should also consider factors like cost, impact, and feasibility when choosing a permanent corrective action and should also conduct a risk assessment to evaluate potential negative outcomes of the actions taken

An implementation or action plan is often useful to document at this stage to detail the steps for implementation, assign responsibilities, and set timelines.

D6: Implement Permanent Corrective Actions

Once verified, implement the corrective actions across all relevant departments or processes. This can involved documenting the new process and training out to all stakeholders involved to ensure the new process is followed and that the stakeholders understand the reason for the change.

At this point you should continue to regularly monitor the situation to ensure the corrective actions are sustained and effective, this could be for a period of 30, 60 or 90 days after the problem was resolved to ensure the new process has become a sustained and issues do not reoccur.

D7: Prevent Recurrence

In D7 to prevent recurrent you should review and update organizational policies or standard operating procedures (SOPs) to prevent a recurrence of the problem and document the new standard process

It is important to conduct regular reviews to continuously monitor the process and ensure procedures are being followed but also to identify further opportunities for process improvement.

D8: Congratulate the Team

The final step D8, after the hard work and successful problem resolution, it is important to acknowledging and congratulating the team is vital for morale and future engagement. With the recognition of a successful 8D Problem-solving activity complete you are more likely to encourage future participation as the method gets a reputation as being useful and successful at solving problems.

Whether it’s a team lunch, certificates of achievement, or simply a public acknowledgment, celebrate the success in a way that resonates with your team.

Finally it is always important to conduct a lessons-learned session and document the insights gained during the process for future reference. This can be used as a future point of reference for problem solving activities.

Mastering the art of problem-solving is crucial in today’s complex and fast-paced environment. The 8D Problem-Solving methodology offers a structured, team-based approach to tackling challenges that can arise in any sector, be it manufacturing, public services, or logistics. This guide has walked you through each of the eight disciplines, offering best practices and highlighting common pitfalls to avoid. We’ve also enriched your understanding through real-world case studies that demonstrate the methodology’s versatility and effectiveness. Remember, the strength of 8D lies not just in identifying and resolving problems, but also in preventing their recurrence through systemic improvements. By adhering to the principles and steps outlined in this guide, you’re well on your way to becoming an adept problem solver, capable of driving continuous improvement in your organization.

- Zarghami, A. and Benbow, D.W., 2017. Introduction to 8D problem solving . Quality Press.

- Camarillo, A., Ríos, J. and Althoff, K.D., 2017. CBR and PLM applied to diagnosis and technical support during problem solving in the Continuous Improvement Process of manufacturing plants . Procedia Manufacturing , 13 , pp.987-994.

Q: What is 8D problem solving?

A: 8D problem solving is a systematic approach used to address and resolve complex problems. It is widely utilized in various industries to identify the root causes of issues, develop effective solutions, and prevent their recurrence.

Q: Why is it called "8D" problem solving?

A: The name “8D” refers to the eight disciplines or steps involved in the problem-solving process. Each discipline represents a specific stage in the methodology, allowing for a structured and comprehensive approach to problem resolution.

Q: What are the eight disciplines (8D) in problem solving?

A: The eight disciplines in problem solving, often abbreviated as 8D, are as follows:

- D1: Form a team

- D2: Define the problem

- D3: Implement containment actions

- D4: Determine the root cause

- D5: Develop and implement corrective actions

- D6: Validate the effectiveness of corrective actions

- D7: Prevent recurrence

- D8: Congratulate the team

Q: What is the purpose of forming a team in the 8D problem-solving process?

A: Forming a team at the beginning of the 8D problem-solving process helps ensure that the right individuals with the necessary expertise are involved in addressing the problem. The team collaboratively works towards understanding the issue, analyzing data, and developing effective solutions.

Q: How is the root cause determined in the 8D problem-solving process?

A: Determining the root cause (D4) involves conducting a thorough analysis of the problem. Various tools and techniques, such as cause-and-effect diagrams, 5 Whys, and data analysis, are employed to identify the underlying factors contributing to the problem.

Q: Can the 8D problem-solving methodology be applied to any type of problem?

A: Yes, the 8D problem-solving methodology is a versatile approach that can be applied to various types of problems across different industries. It provides a structured framework for problem resolution and can be tailored to suit the specific needs and requirements of different situations.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Download Template

Free lean six sigma templates.

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

How it works

For Business

Join Mind Tools

Article • 4 min read

The Problem-Solving Process

Looking at the basic problem-solving process to help keep you on the right track.

By the Mind Tools Content Team

Problem-solving is an important part of planning and decision-making. The process has much in common with the decision-making process, and in the case of complex decisions, can form part of the process itself.

We face and solve problems every day, in a variety of guises and of differing complexity. Some, such as the resolution of a serious complaint, require a significant amount of time, thought and investigation. Others, such as a printer running out of paper, are so quickly resolved they barely register as a problem at all.

Despite the everyday occurrence of problems, many people lack confidence when it comes to solving them, and as a result may chose to stay with the status quo rather than tackle the issue. Broken down into steps, however, the problem-solving process is very simple. While there are many tools and techniques available to help us solve problems, the outline process remains the same.

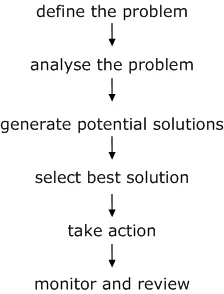

The main stages of problem-solving are outlined below, though not all are required for every problem that needs to be solved.

1. Define the Problem

Clarify the problem before trying to solve it. A common mistake with problem-solving is to react to what the problem appears to be, rather than what it actually is. Write down a simple statement of the problem, and then underline the key words. Be certain there are no hidden assumptions in the key words you have underlined. One way of doing this is to use a synonym to replace the key words. For example, ‘We need to encourage higher productivity ’ might become ‘We need to promote superior output ’ which has a different meaning.

2. Analyze the Problem

Ask yourself, and others, the following questions.

- Where is the problem occurring?

- When is it occurring?

- Why is it happening?

Be careful not to jump to ‘who is causing the problem?’. When stressed and faced with a problem it is all too easy to assign blame. This, however, can cause negative feeling and does not help to solve the problem. As an example, if an employee is underperforming, the root of the problem might lie in a number of areas, such as lack of training, workplace bullying or management style. To assign immediate blame to the employee would not therefore resolve the underlying issue.

Once the answers to the where, when and why have been determined, the following questions should also be asked:

- Where can further information be found?

- Is this information correct, up-to-date and unbiased?

- What does this information mean in terms of the available options?

3. Generate Potential Solutions

When generating potential solutions it can be a good idea to have a mixture of ‘right brain’ and ‘left brain’ thinkers. In other words, some people who think laterally and some who think logically. This provides a balance in terms of generating the widest possible variety of solutions while also being realistic about what can be achieved. There are many tools and techniques which can help produce solutions, including thinking about the problem from a number of different perspectives, and brainstorming, where a team or individual write as many possibilities as they can think of to encourage lateral thinking and generate a broad range of potential solutions.

4. Select Best Solution

When selecting the best solution, consider:

- Is this a long-term solution, or a ‘quick fix’?

- Is the solution achievable in terms of available resources and time?

- Are there any risks associated with the chosen solution?

- Could the solution, in itself, lead to other problems?

This stage in particular demonstrates why problem-solving and decision-making are so closely related.

5. Take Action

In order to implement the chosen solution effectively, consider the following:

- What will the situation look like when the problem is resolved?

- What needs to be done to implement the solution? Are there systems or processes that need to be adjusted?

- What will be the success indicators?

- What are the timescales for the implementation? Does the scale of the problem/implementation require a project plan?

- Who is responsible?

Once the answers to all the above questions are written down, they can form the basis of an action plan.

6. Monitor and Review

One of the most important factors in successful problem-solving is continual observation and feedback. Use the success indicators in the action plan to monitor progress on a regular basis. Is everything as expected? Is everything on schedule? Keep an eye on priorities and timelines to prevent them from slipping.

If the indicators are not being met, or if timescales are slipping, consider what can be done. Was the plan realistic? If so, are sufficient resources being made available? Are these resources targeting the correct part of the plan? Or does the plan need to be amended? Regular review and discussion of the action plan is important so small adjustments can be made on a regular basis to help keep everything on track.

Once all the indicators have been met and the problem has been resolved, consider what steps can now be taken to prevent this type of problem recurring? It may be that the chosen solution already prevents a recurrence, however if an interim or partial solution has been chosen it is important not to lose momentum.

Problems, by their very nature, will not always fit neatly into a structured problem-solving process. This process, therefore, is designed as a framework which can be adapted to individual needs and nature.

Join Mind Tools and get access to exclusive content.

This resource is only available to Mind Tools members.

Already a member? Please Login here

Get 20% off your first year of Mind Tools

Our on-demand e-learning resources let you learn at your own pace, fitting seamlessly into your busy workday. Join today and save with our limited time offer!

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

Pain Points Podcast - Balancing Work And Kids

Pain Points Podcast - Improving Culture

Mind Tools Store

About Mind Tools Content

Discover something new today

Pain points podcast - what is ai.

Exploring Artificial Intelligence

Pain Points Podcast - How Do I Get Organized?

It's Time to Get Yourself Sorted!

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

Top tips for staying focused.

If You Have Trouble Concentrating These Tips Will Help You Focus

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Team Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

COMMENTS

The eight steps to practical problem solving also include the Plan, Do, Check and Act (PDCA) cycle. Steps one through five are the planning process. The doing is found in step six. Step seven is the checking . Step eight involves acting out the results of the new standard. This practical problem solving can be powerful tool to issues facing ...

Step 8: Continuously Improve. Look for additional opportunities to implement solution. Ensure problem will not come back and communicate lessons learned. If needed, repeat the 8-Step Problem Solving Process to drive further improvements. 8-Step Problem Solving Process.

Step 2: Break Down The Problem. For this next step, you need to start getting more detailed and specific. Break down the problem into manageable pieces, go see the problem in the process, analyze the issues, and start thinking about priorities. The Stormboard Template for this step is divided into three sections: Get Your Boots On and Go See ...

The 8-step problem-solving process is a powerful tool for tackling complex problems and driving organizational success. By following each step in a systematic and structured manner, you can define ...

The 8 Steps and the Problem-Solving Process. The Culture of Problem-Solving. Plan, Do, Check, Act (PDCA) Gain Problem-Solving Support. As a manufacturing professional, you know how important it is to stay organized, keep your goals in mind and strive for success. But with all of the responsibilities and daily tasks piling up, it takes effort to ...

Summary. Problem management is an 8 step framework most commonly used by IT teams. You can use problem management to solve for repeating major incidents. By organizing and structuring your problem solving, you can more effectively get to the root cause of high-impact problems—and devise a solution. Solving the root cause prevents recurrence ...

8D Problem Solving is a systematic and structured approach used to solve business related problems. It names has been given by the fact there are 8 steps or 8 disciplines that are followed to identify, correct and eliminate recurring problems. 8D Problem Solving is regarded as robust methodology that has proven its worth across multiple ...

2. Break down the problem. Breaks the problem into manageable, understandable pieces. Identifies the point of occurrence Answers the question:" Where does this problem occur?" 3. Set the target. Sets a specific, measurable, and challenging target for closing the gap from step 1 Might begin with words like “Reduce“, “Increase ...

Finding a suitable solution for issues can be accomplished by following the basic four-step problem-solving process and methodology outlined below. Step. Characteristics. 1. Define the problem. Differentiate fact from opinion. Specify underlying causes. Consult each faction involved for information. State the problem specifically.

The Problem-Solving Process. Problem-solving is an important part of planning and decision-making. The process has much in common with the decision-making process, and in the case of complex decisions, can form part of the process itself. We face and solve problems every day, in a variety of guises and of differing complexity.