How Does GE Do Performance Management Today?

When it comes to discussing performance management, it’s impossible to skip Jack Welch’s “rank-and-yank” review tactics back in the 1980s. During a time when the economic reality at GE demanded efficiency and operational excellence, the company became well-known for its hard-charging and intense approach to performance reviews.

The company has since undergone much change in their style and performance management process. Today they conduct a more evenly distributed and ongoing review process. The focus is less on rating and ranking and more on developing, connecting, and inspiring employees.

Here is what performance management looks like at GE today.

Performance management at GE

GE rolled out its new performance management strategy at the end of 2016, replacing its legendary Employee Management System that was implemented in 1976 and widely emulated by other companies. The change took place largely due to a program launched in 2013 called FastWorks, which introduced skills and processes to make GE a more lean, agile, and customer-centered organization.

Under the new direction of CEO Jeff Immelt, GE began to shift from annual performance reviews to a system that accommodated the lean and innovative methodology of Fastworks. The organization developed a simple, contemporary smartphone app, designed with the sole purpose of facilitating more frequent communication and meaningful conversations between managers and employees.

The app , called PD@GE, exchanges voice and text input, attached documents, and even handwritten notes between employees, managers, and teams across the company. The organization’s goal was to shift their employee review focus onto continuous dialogue and shared accountability. The app facilitates a constant exchange of feedback year-round; participants can receive suggestions from anyone in their network, including upper management and members of other teams.

In order to continue in the vein of customer-centered growth, GE’s IT team developed the app so that managers can hold regular “touchpoints” with employees in order to set goals and update priorities based on customer needs. At its core, the app serves as a platform to define goals for employees and to enable constant improvement for all users.

While many of the headlines and articles detailing the legendary company’s migration from annual cycles and stack rankings may lead people to believe it’s been a neat and succinct transition, the question begs to be asked: Has GE really gotten rid of annual rankings entirely?

Summary Conversations

As stated previously, one of GE’s main aims in their performance review strategy is to facilitate recurring, meaningful conversations between managers and employees. Along with continuous feedback through the PD@GE app, the company also mandates yearly summary conversations where employees and managers finalize and submit a summary document together.

During the meeting, employees and managers reflect upon goals met and impact achieved, while casting vision for future goals to be met. These meetings act as an existing piece of the old EMS structure, and operate just as they did before -- with managers basing compensation, promotion, and development decisions on the input provided.

However, with the introduction of the new performance-development approach, these year-end conversations exist as more of an ongoing dialogue rather than a one-time meeting that is loaded with expectations. This allows the conversations to be more meaningful and future-focused, and informed by more specific data of an employee’s contributions and achievements throughout the year.

In a Harvard Business Review article , GE executives Leonardo Baldassarre and Brian Finken describe GE’s new performance-development approach as an attempt to shift the company’s focus from “command and control” to “empower and inspire.” Judging by the company’s latest increase in productivity and significant benefit yield for customers, it’s working.

But how do their employees feel about the change? Let’s take a look at some anonymous Glassdoor reviews to get a glimpse of how GE’s work culture has shifted along with their performance review strategy.

What Employees Say

“Great company to work for even while being one of the largest corporations in the world. Never have to worry about not having a job. They seem to care about the ‘little’ guy as much as possible.”

“Best company I have ever worked for. The company knows how to motivate employees and get ahead of competition. Even through rough times they are still competitive in areas. Leaders are trained unlike other companies where managers and leaders are terrible and untrained.”

“World-class training programs and people development. Very smart leadership, great to learn from. Strong organization around the business cycle, you know what to expect. Work/life balance is good, if you make it a priority.”

“Work culture is too good, people around are very professional. Company is very secure for female employees. Offers good work life balance as flexible work hours are allowed. No punch in/punch out needed as GE believes in their employees. Lateral/vertical movement is appreciated after every 3 years.”

“Very big company so it makes you feel unconnected to some of the things that go on. Many times it is difficult to get a straight answer when important, company-wide news comes out. Progressively changing a huge company takes time, don’t expect culture to change overnight.”

“Management can be clueless. Culture has been rough the past few years with layoffs and reduction in force. HR controls a lot of the decisions, with little line of sight to what’s actually happening. And too many buzzwords.”

“Back in the day when Jack Welch was at the helm, GE was run like a well oiled machine. The stock split, GE was good. GE was diversified and the pension was funded. Things changed when Jeff Immelt came and took charge and totally screwed up GE, he did not do what was best for the company, nor did the board of directors. They kept the problem going on for over 16 years. Replacing Immelt and not giving John Flannery enough time to fix a 16 year mess was wrong. After 39 years, this is not the GE I started with. I was embarrassed at the end to say I worked for this company.”

So, has GE’s management served to “empower and inspire” its employees as they set out to do when they shifted their performance management approach?

It may be that time will tell. However, it’s safe to say that many positive changes have occurred during the company’s transitional phase that have impacted many individual pockets of the organization -- and perhaps the most significant is the culture.

Leader of cultural transformation at GE, Janice Semper, set out to change the company’s operations and solutions for its customers by first looking inwardly at the mindsets and behaviors of its employees. The organization has made many strides to change the language and the way that many processes are done in order to promote a sustainable, collaborative, and empowered employee environment.

At the end of the day, GE’s performance management strategy focuses on people and dialogue -- meaning that intensive conversations and enormous chunks of time are dedicated to ensure that each employee is exhaustively evaluated both on what they’ve accomplished and how they lead. Attention is given to each individual appraisal, and manager’s assessments can be questioned or given feedback to ensure that the quality of each appraisal is honest and comprehensive.

And clearly, it’s working -- one of the most repetitive “pros” found in GE’s anonymous Glassdoor reviews is the company’s culture.

So, while it’s hard to say whether or not GE has abandoned its old system for good, it is certain that there have been benefits to both of the company’s major performance review systems. The company would not be what it is today without its Six Sigma, rank-and-yank of the Welch era, and is experiencing continued growth and profound success as they continue to adapt their appraisal process to the needs of their organization in an ever-changing business environment.

More Inspiration

GE is not the only organization going its own way. These days, most great organizations are thinking critically about performance management and coming up with innovative new solutions.

Here are a few more examples to help inspire your own strategy:

Google’s Performance Management Playbook: Inspiration for Your Organization

3 Approaches to Performance Management: Google, Betterment and IBM

How does Facebook do Performance Management

Performance Management at Tesla : What we know.

How Regeneron Built Their Performance Management System

How Does Uber Do Performance Management?

How Does Asana Do Performance Management?

How Netflix does Performance Management

Deloitte's Radically Simple Review

How Does Amazon Do Performance Management

And if you're ready to take the next step, check out our guide to creating your own modern performance management process .

The tools to streamline your performance management process.

Bring your performance management to life.

How to Set Up an Employee Mentorship Program

Talent Development: 7 Steps to Develop Top Talent

First 90 Days as New HR Manager - 2024 Action Plan

Brought to you by:

Performance Development at GE: Shaping a Fit-For-Purpose Performance Management System (C)

By: Anand Narasimhan, Jennifer Jordan, Shih-Han Huang

In 2013, GE implemented the FastWorks program, an initiative that utilized tools and methods adapted from start-up methodologies to make the company more customer centric, lean and agile. With the…

- Length: 9 page(s)

- Publication Date: Sep 21, 2018

- Discipline: Human Resource Management

- Product #: IM1012-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$2.95 per student

degree granting course

$5.45 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

In 2013, GE implemented the FastWorks program, an initiative that utilized tools and methods adapted from start-up methodologies to make the company more customer centric, lean and agile. With the spread of FastWorks within GE, a startling conclusion became evident - the existing performance management system might no longer be fit for the company's new direction. This case series follows the journey of GE's new performance management system, Performance Development, and its PD@GE app. By utilizing FastWorks in its development process, the HR team was able to leverage customer feedback and rapid prototyping to build a new system with unique features, such as instantaneous feedback, upward feedback and removal of employee ratings.

Learning Objectives

Identify the need to align appraisals and incentives to complement company strategy; discover success factors for working in an agile manner in a complex organization; explore best practices in change management; adapt HR processes for the next generation of workers.

Sep 21, 2018

Discipline:

Human Resource Management

Geographies:

United States

Industries:

Airline industry, Human resource services, Medical equipment and devices

IM1012-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

Data and Analytics Case Study

Made possible by ey, exclusive global insights case study sponsor.

GE’s Big Bet on Data and Analytics

Seeking opportunities in the internet of things, ge expands into industrial analytics., february 18, 2016, by: laura winig, introduction.

If software experts truly knew what Jeff Immelt and GE Digital were doing, there’s no other software company on the planet where they would rather be. –Bill Ruh, CEO of GE Digital and CDO for GE

In September 2015, multinational conglomerate General Electric (GE) launched an ad campaign featuring a recent college graduate, Owen, excitedly breaking the news to his parents and friends that he has just landed a computer programming job — with GE. Owen tries to tell them that he will be writing code to help machines communicate, but they’re puzzled; after all, GE isn’t exactly known for its software. In one ad, his friends feign excitement, while in another, his father implies Owen may not be macho enough to work at the storied industrial manufacturing company.

Owen's Hammer

Ge's ad campaign aimed at millennials emphasizes its new digital direction..

The campaign was designed to recruit Millennials to join GE as Industrial Internet developers and remind them — using GE’s new watchwords, “The digital company. That’s also an industrial company.” — of GE’s massive digital transformation effort. GE has bet big on the Industrial Internet — the convergence of industrial machines, data, and the Internet (also referred to as the Internet of Things) — committing $1 billion to put sensors on gas turbines, jet engines, and other machines; connect them to the cloud; and analyze the resulting flow of data to identify ways to improve machine productivity and reliability. “GE has made significant investment in the Industrial Internet,” says Matthias Heilmann, Chief Digital Officer of GE Oil & Gas Digital Solutions. “It signals this is real, this is our future.”

While many software companies like SAP, Oracle, and Microsoft have traditionally been focused on providing technology for the back office, GE is leading the development of a new breed of operational technology (OT) that literally sits on top of industrial machinery. Long known as the technology that controls and monitors machines, OT now goes beyond these functions by connecting machines via the cloud and using data analytics to help predict breakdowns and assess the machines’ overall health. GE executives say they are redefining industrial automation by extracting lessons from the IT revolution and customizing them for rugged heavy-industrial environments.

One such environment is the oil and gas industry, where GE sees a $1 billion opportunity for its OT software. In an industry where a single unproductive day on a platform can cost a liquified natural gas (LNG) facility as much as $25 million, the holy grail for oil and gas is minimizing “unplanned downtime” — time that equipment is unable to operate due to a malfunction. Ashley Haynes-Gaspar, software and services general manager at GE Oil & Gas, notes that refining operations are typically tightly run but are in hard-to-access, remote locations. Increasing uptime is critical — particularly with oil prices at their lowest in six years. “An average midsize LNG facility sees five down days a year. That’s $125 million to $150 million. For an offshore platform, it can be $7 million per day, including oil deferrals, and these assets are never down for a single day. They have got to figure out how to drive productivity in their existing assets,” she says, “especially now that they are facing declining revenues from lower energy prices.”

What Is the Industrial Internet?

Ge is developing an industrial internet platform for the oil and gas sector..

Improving the productivity of existing assets by even a single percentage point can generate significant benefits in the oil and gas sector (and in other sectors). “The average recovery rate of an oil well is 35%, meaning 65% of a well’s potential draw is left in the earth because available technology makes it too expensive,” explains Haynes-Gaspar. “If we can help raise that 35% to 36%, the world’s output will increase by 80 billion barrels — the equivalent of three years of global supply. The economic implications are huge.”

GE executives believe software, data, and analytics will be central to the company’s ability to differentiate itself within the oil and gas industry. “I think the race is on from a competition perspective,” says Haynes-Gaspar, “and everybody understands the size of the Industrial Internet prize.”

The Software Behind GE’s Industrial Internet

In September 2015, GE projected its revenue from software products would reach $15 billion by 2020 — three times its 2015 bookings. While software sales today are derived largely from traditional measurement and control offerings, GE expects that by 2020, most software revenue will come from its Predix 1 software, a cloud-based platform for creating Industrial Internet applications.

GE has long had the ability to collect machine data: Sensors have been riding on GE machines for years. But these pre-Internet of Things (IoT) sensors were used to conduct real-time operational performance monitoring, such as displaying a pressure reading on a machine, not to collect data. Indeed, a technician would often take a reading from a machine to check its performance and then discard the data.

GE researched companies that were producing high-quality data analytics quickly and inexpensively, but it wasn’t the traditional IT companies that were excelling; it was the consumer-facing Internet giants. GE drew lessons from these companies around speed and cost, though the scale and data were different. Indeed, the sheer volume of data that GE hoped to collect — 50 million data variables from 10 million sensors installed on its machines — would be many times more than most social and retail sites could ever generate. “Machines generate time-series data, which is very different than social or transactional data. We had to optimize for the kinds of analytics that would help us understand the behavior of machines,” says Bill Ruh, GE’s chief digital officer.

To handle these massive data sets, GE needed a new platform for connecting, securing, and analyzing data. They began developing their solution in 2012, a cloud-based software platform named Predix that could provide machine operators and maintenance engineers with real-time information to schedule maintenance checks, improve machine efficiency, and reduce downtime. Initially developed for GE, not only would this data inform their own product development activities, but it would also lower costs in its service agreements. “When we agree to provide service for a customer’s machine, it often comes with a performance guarantee,” explains Kate Johnson, vice president and chief commercial officer, GE Digital. “Proactive identification of potential issues that also take the cost out of shop visits helps the customer and helps GE.”

It didn’t take long for GE engineers to realize that they could find interesting and unique patterns in the data. They thought the patterns of sensor data could be used to provide an early — albeit weak — signal of future performance problems and better predict when its machines should be scheduled for maintenance. In early 2013, GE began to use Predix to analyze data across its fleet of machines. By analyzing what differentiated one machine’s performance from another — what made one more efficient, for example — GE could more tightly hone its operational parameters. “We’re moving from physics-based modeling, where you create maintenance manuals based on generic operating models, to combining it with very high-performance analytics,” says Ruh. When GE combined the physics modeling and the data modeling, it found that, in Ruh’s words, it could “do what no one’s ever done in the world before for industry.”

Predix: GE's Platform for the Industrial Internet

Ge develops an internet of things platform to drive productivity..

For example, in the last few years, GE started to notice that some of its jet aircraft engines were beginning to require more frequent unscheduled maintenance. “If you only look at an engine’s operating parameters, it just tells you there’s a problem,” says Ruh. But by pulling in massive amounts of data and using fleet analytics, GE was able to cluster engine data by operating environment. The company learned that the hot and harsh environments in places like the Middle East and China clogged engines, causing them to heat up and lose efficiency, thus driving the need for more maintenance. GE learned that if it washed the engines more frequently, they stayed much healthier. “We’re increasing the lifetime of the engine, which now requires less maintenance, and we think we can save a customer an average of $7 million of jet airplane fuel annually because the engine’s more efficient,” Ruh explains. “And all of that was done because we could use data across every GE engine, across the world and cluster fleet data.” Johnson credits Predix directly with improving the productivity of these engines, as this would not have been possible without a robust data and analytics platform.

That same year, GE executives began to think there could be a market opportunity for Predix, much as Amazon.com Inc. created a market for its cloud-computing platform, Amazon Web Services Inc. “We realized that there were three developing markets for cloud platforms — consumer, enterprise, and industrial. Industrial was essentially being treated as an extension of enterprise, which we knew wouldn’t work. There were no credible cloud-based platforms for industrial being developed, and we saw that as a potential opportunity for growth,” says Ruh. Why now? GE executives say the economics of amassing, storing, and running analytics on large lakes of data — pools of customer data that combine maintenance and repair data with time-series performance information — have dropped dramatically in the last 10 years, making the market viable.

The driving force behind taking Predix to market was the scope of the opportunity: GE determined that the market for a platform and applications in the industrial segment could reach $225 billion by 2020. 2 GE spent a year evaluating the market, all the while using Predix 1.0 to further develop its offerings and collect internal and external feedback. The company built a team to develop the commercial version, Predix 2.0, and in October 2015 made the platform directly available to channel and technology partners as well as customers who could use the platform to build their own set of analytics. “We feel we’ve got it right for ourselves, and now we’re taking it out to customers and partners,” says Ruh.

A New Approach to Oil and Gas

GE has enjoyed success as a physical infrastructure provider, known worldwide as the company that “brings good things to life.” But that corporate identity is beginning to shift. “When we think about the future, digitizing our customers’ businesses requires a technology shift, a business model shift, and a skill shift,” says Ruh, noting that GE and its customers will need to optimize all three to be successful. Indeed, in the oil and gas sector, where customers have been struggling to improve productivity amid declining revenues, GE is using Predix to transform what it’s selling, how it’s selling, and who is invited to the negotiating table.

Delivering New Services to a Conservative Market

GE entered the oil and gas industry in 1994 through the acquisition of Italy-based Nuovo Pignone, a manufacturer of turbo machinery, compressors, pumps, static equipment, and metering systems. Just over 20 years later, GE’s oil and gas subsidiary has become a roughly $20 billion business, ranging from oil and gas drilling equipment and subsea systems to turbo machinery solutions and downstream processing. The company considers itself a “full-stream” provider, operating across the entire oil and gas value chain: upstream exploration and production, midstream transportation (via pipeline, oil tanker, or the like) and storage of crude petroleum products, and downstream refining of petroleum crude oil and processing of natural gas.

GE’s customers in the oil and gas market are known for being conservative, a necessity in the highly dynamic and sometimes harsh environments in which they work. “They wait for their peers to try something new, and if it’s successful and they see there’s value in it without added risk, they jump all over it,” says Steve Schmid, GE senior product manager. As a result, GE runs pilots — lots of pilots. “I tell customers about a new product and a pilot we’re doing with a highly respected operator in their industry. They say, ‘Fantastic, keep us up to speed on your progress. Once you’ve got a product released, we want to know the results, and then we’ll be interested in entertaining moving forward with a proposal.’ But it’s difficult to take that first leap,” says Schmid. “However, those that do so are the first to gain an incredible competitive advantage in the market — and others are soon a fast follow.”

Jeff Monk, GE’s global key account executive for North America, adds: “In general, oil and gas companies like to keep things close to their chests. They don’t see a lot of value in publicizing the details of their operations — whether those be big wins or big saves. If a customer can save $100 million as a result of data analytics, that’s great, but they will be concerned about publicizing that because they believe stakeholders will think they might not have avoided those costs. Oil and gas companies have to come to terms with the market’s need for them to be more transparent, and the added value that data and analytics provide is relatively new, so that issue is somewhat mitigated.”

GE’s Intelligent Pipeline

Ge uses the industrial internet to improve safety and lower risk for pipeline operators., new service value propositions.

GE believes Predix can help the oil and gas industry address four of its most pressing challenges: improving asset productivity; creating a real-time picture of the status of an entire operation; stemming the costly loss of tacit knowledge from an aging workforce; and building an Industrial Internet platform that meets customer needs.

Asset Productivity

GE had spent years developing analytic applications to improve the productivity and reliability of its own equipment, with oversight from GE global monitoring centers. GE’s strategy is to deploy these solutions and then expand to include non-GE plant equipment as part of the solution. GE’s work with RasGas Company Limited, one of the world’s foremost integrated LNG enterprises, is an example of that approach. RasGas’s LNG production facility in Ras Laffan, Qatar — where over 2,000 critical assets are installed — has the capacity to produce approximately 37 million tons of LNG per year.

GE’s equipment specialists and analytic scientists, who were already monitoring the GE turbine components of the RasGas production power trains, worked closely with RasGas operations experts to enhance LNG productivity overall, including the non-GE components. This close collaboration identified critical components, failure modes, and process challenges.

In an initial proof of concept, the team focused on three LNG trains. Their primary goal was to demonstrate that a suite of next-generation predictive analytics tools could enhance asset reliability and maintenance effectiveness while optimizing processes. In early results of the asset performance management (APM) solution implementation, the team identified areas of improvement to eliminate wastes in production on one of the trains, which will translate to a significant LNG production improvement. Today, GE and RasGas are working in conjunction toward a full-plant APM solution deployment at the Ras Laffan site.

Operations Productivity

GE wants to go beyond helping its customers manage the performance of individual GE machines to managing the data on all of the machines in a customer’s entire operation. For example, if an oil and gas customer has a problem with a turbo compressor, a heat exchanger upstream from that compressor may be the original cause of the problem. Analyzing data from the turbo compressor will thus only tell part of the story. “We’re selling equipment that sits side by side with competitors’ equipment. Our customer cares about running the whole plant, not just our turbine,” says Johnson. GE is in discussions with some customers about managing sensor data from all of the machine assets in their operation.

Customers are asking GE to analyze non-GE equipment because those machines comprise about 80% of the equipment in their facilities. “They want GE to help keep the whole plant running. They’re saying, ‘It does me no good if my $10 million gas turbine runs at 98% reliability if I have a valve that fails and shuts my entire plant down,’” explains Dan Brennan, executive director for the Industrial Internet for GE Oil & Gas. Indeed, capital-intensive equipment such as gas turbines are already well-instrumented with sensors and data controls. “They’re well-protected to make sure they’re reliable,” he says. The supporting, smaller-investment equipment often did not warrant the cost of instrumentation and data gathering. But industry thinking has evolved as the cost of getting data from those less expensive assets has declined logarithmically, opening up a whole new world of monitoring by looking at the system not as a collection of critical equipment but as an ecosystem. For one pilot program with a major customer, GE is analyzing data on all their rotating and static equipment — regardless of the machines’ original equipment manufacturer (OEM). The first phase is on all 160 of the customer’s gas turbines across the world, even though only 40% of them are GE gas turbines. GE characterizes it as an “agnostic” solution.

How do the OEMs feel about having their equipment monitored by GE? Erik Lindhjem, executive product line leader for GE Oil & Gas, acknowledges that some competitors are more comfortable with the idea than others. “I think there’s an uneasiness for some of the GE OEM competitors about how the data’s collected and our reach into it. However, ultimately it’s the end user — our mutual customer — who drives the use of the technology and the data,” says Lindhjem. GE also points out that its competitors are quietly exploring the same strategy, albeit not by building it themselves but by partnering with other software providers. Siemens has entered into a partnership with SAP, while Solar Turbines, a Caterpillar company, has partnered with a startup, Uptake, to try to equalize the value proposition that GE is bringing to market.

Because Predix is an open platform, GE Oil & Gas Digital Solutions CDO Heilmann emphasizes that GE encourages developers to write applications to support their own needs. “I can see a day in the future where we would encourage other OEMs, whether it’s a pump or a fan or a valve manufacturer, to participate in the Predix ecosystem and write applications for their own equipment and use the data to improve the operation of their own equipment,” he says.

In today’s oil and gas industry, operators seldom share data and collaborate with one another. “Operators view that data as a source of competitive advantage,” says Brennan. Schmid agrees, noting that oil and gas operators differentiate themselves by the way they operate: “They can buy the same tools, the same type of equipment. And they have very few choices in suppliers. We’re not at a point where they’re going to start sharing how their operational excellence gets them a lower cost per barrel of oil than their competitors. Today, the only cross-operator data they are interested in is baselining against their competitors on how they perform, but not sharing how they actually drive up their efficiency over their competitors.”

Brennan says oil and gas companies are unlikely to ever share data around their exploration activities, but he could imagine a day when they might be willing to share operational data. “Maybe five or six years from now, we’ll begin to see companies more willing to share data that could unlock new levels of collaboration across the entire supply chain. They might start to release pockets of data if they realize they can learn from each other and drive efficiencies back into the entire industry,” he says. One path forward would be by sharing anonymized data. Maybe. “I’m hopeful because I think that’s where you’re going to see the next tranche of value.”

GE has already begun to discuss the idea of anonymizing data with customers, but without much success. “We’ve said, ‘What if you could see how you were doing relative to everybody else in the industry on a completely anonymized basis?’ And everybody’s response has been, ‘That’s great, but my data won’t be in the set,’” says Haynes-Gaspar, though she, too, is optimistic that given time and perspective, the industry will likely come to embrace sharing. “Because the things that are differentiating for them today will change based on how the Industrial Internet shapes where we’re going,” she says.

GE Digitizes Experience-Based Knowledge

Ge develops a software solution to meet the challenge of a workforce in flux., support for an aging workforce.

A large portion of the oil and gas workforce — by some estimates as much as 50% — will be retiring by 2025, taking years and even decades of domain knowledge with them. “There’s a lot of knowledge in people’s heads that has not been digitized, documented, and built into practice,” says Brad Smith, business leader for the GE Oil & Gas Intelligent Pipeline business unit. He says some companies with multimillion-dollar operations are dependent upon too few individuals whose domain knowledge can be very difficult to replace, which will challenge the industry to maintain or improve workforce productivity.

The retirement problem is most visible upstream, during the exploration process and at the oil wells themselves. Ron Holsey, Digital Commercial Leader, Surface, GE Oil & Gas, explains:

As we bring a well into production, the natural pressure of the reservoir makes the oil flow to the surface. Over time, that pressure subsides and operators need artificial lift to pull the oil out of the ground. The engineers in the field have 20, 30, 40 years of experience — they’re like pumping-unit whisperers. They can walk up to a unit, and they can hear it creak and groan and grind and understand the stress points. Today, if you’re at a university studying to be a petroleum engineer, you get maybe one textbook chapter during your four years on artificial lift. We just don’t have the next wave of engineers coming up.

To stanch the brain drain over the past few years, many companies have been forced to hire back retiring workers to serve as consultants — an unsustainable practice. Brennan says that the industry needs a way to capture and codify the departing knowledge. “But there’s also got to be a refresh so that you can attract new talent and arm them with tools, technology, and the capability to get their work done efficiently,” he says. “The tools that a 26- or 28-year-old PhD in petroleum engineering wants to use are fundamentally different than ones preferred by somebody who’s leaving the workforce,” he adds, noting that Millennials expect that cutting-edge analytics and tools will be available in the workplace. “When I entered the workforce, I had better tools at work than I’d ever had access to at home, but most of the employees we bring into GE have access to better technology than we allow them here, and we’ve been playing catch-up. The same thing is happening with our customers,” says Brennan.

GE hopes to use Predix to help its oil and gas customers fill the industry’s talent and knowledge gap, but there are challenges associated with trying to essentially supplant human experience with analytics. For one, the industry is extremely slow to adopt new technology. A related problem is getting engineers to trust the data. GE had well-analysis software that could determine if a pump was operating at its optimal range and adjust its speed to run faster or slower to optimize production. Despite several case studies and a pilot on 30 wells showing an incremental gain of 1 million barrels of oil over two years, GE’s customers will not allow the software to change pump speeds on its own. “We still have to have the human intervention. Why? The customer and the industry are reluctant to adopt the new technology,” says Holsey.

Platform Benefits

Predix was designed to be a software platform, not just a tool for collecting, analyzing, and managing sensor data. For GE customers, this approach is expected to have several benefits. The platform has open standards and protocols that allow customers to more easily and quickly connect their machines to the Industrial Internet. The platform can accommodate the size and scale of industrial data for every customer at current levels of use, but it also has been designed to scale up as demand grows. The number and variety of Predix-related apps are not limited to what GE offers. Whereas customers may develop their own custom applications for use on the Predix platform, GE executives are working to build a developer community and create a new market for apps that can be hosted on the Predix platform. Finally, data security, a concern for many companies considering IoT applications, is embedded at all platform application layers: services enablement, data orchestration, and infrastructure layers.

Transforming the Sales Process

GE’s traditional sales model within the oil and gas industry has been big-ticket and transactional: Customers purchased machines, as well as parts, maintenance, and repair service contracts at fixed prices — what Brennan refers to as a tactical, product-centric sales model.

Adding Predix software to the mix has made the sales process more complex and much less product-centric, even though the new software represents a relatively small sell — a “tiny little sprinkling on top of the deal,” says GE Digital’s Johnson. GE’s salespeople, for instance, have to engage in more strategic conversations around solutions rather than product features. Software technicians are involved earlier in the selling process. “Now, when we sell an electronic submersible pump,” says Johnson, “the equipment sales manager brings along an application engineer who understands technically how that pump is going to operate in the environment in which it’s going to be placed. You need the same exact set of capabilities when you’re talking about software. You need to know how it fits into the overall solution architecture of hardware, software, and service. Your typical hardware sales leader doesn’t have the Predix domain knowledge to have that conversation for software.”

Not surprisingly, GE has had to address internal resistance to the shift away from a productcentric sales focus. “It was definitely a change in how our sales personnel approach customer conversations,” says Lorenzo Simonelli, president and CEO of GE Oil & Gas. “Instituting software-solution selling techniques required us to embark on both a training exercise and an effort to infuse our organization with software selling expertise, working with our GE industry experts who have held customer relationships for decades. Additionally, these types of digital conversations and sales decisions now involve new customer participants. We needed to understand these roles so each could become Industrial Internet champions in their respective organizations.”

GE is finding that its traditional buyer — typically a VP of operations or plant manager — is changing too, as increasingly the CIO now takes a seat at the table. In the past, GE’s salespeople never brought customers’ CIOs into the selling process; they spent most of their time in the production and engineering offices. But selling software is completely different than selling hardware. “You’ve got different stakeholders, like the CIO and the CTO, suddenly coming into the story,” says Johnson. Smith agrees that CIOs and CTOs are becoming critical stakeholders and have places at the table — though he still believes the decision making will reside with the COO. “Operations will define the requirements and agree on the scope because the IT teams will inherently not bring the domain expertise that their operational partners have acquired through years of practice,” he says. “But the programs, large and small, will be governed, purchased, and project-managed out of the IT organization.” Indeed, Johnson says CIOs may end up being the true heroes of the digital industrial space: “CIOs are starting to wake up to the enormous opportunity they have in the operational technology space where they have traditionally not been a part of decision making.”

Though many of GE Oil & Gas customers are already familiar with the company’s software offerings, Predix adds another dimension to the conversation. “Generally we’re first met with, ‘Well, what is this Industrial Internet?’” says Brennan. Typically, a discussion around system architecture ensues. “CIOs’ concerns are around connectivity,” says Holsey. “The challenge is, instead of the old ‘rack it and stack it and have servers sitting in the client’s office,’ do I go to a cloud-based system?” Customers are starting to come around, particularly U.S. companies. “They have started to evolve from, ‘That’s the most insane thing I’ve ever heard of, putting it on a cloud,’ to, ‘Wow, it’s easier to maintain and I don’t have to worry about keeping my servers up to date.’ There’s more acceptance now,” says Holsey. However, he thinks it will take another three to five years to become commonplace: “Then, there won’t be a question of whether a cloud or not a cloud.”

GE sales teams were finding that one of the most significant value propositions they had to offer customers was the creation of data lakes that sit on the cloud and enable data sharing and analytics. “Today, those systems don’t talk. But with Predix, customers are able to have a data lake, their data in a central repository,” says Haynes-Gaspar. As a result, oil and gas operators with operations in disparate parts of the world can allow local operators to share vital, problem-solving data.

Selling by Pilot

For GE, a pilot is often an essential step of the adoption process. In early 2015, GE executed a four-week engagement with one of the largest global energy companies, which wanted to reinvent how it manages its “static” equipment — specifically, its storage tanks used during oil and gas processing. Like other producers, this company spends heavily on maintaining these assets from corrosion and other threats but because they aren’t instrumented, they are inspected infrequently, often once every two or three years. GE positioned Predix to help the customer rethink how it manages them. During the four-week exercise, GE’s designers met with the customer’s subject-matter experts, corrosion engineers, and reliability engineers. At the end of the four weeks, GE developed a software solution that took the form of a scripted narrative on a static set of screens. The customer used the screens to “walk through” how its reliability engineers could use them to better manage its static assets. Though the project was successful in its own right, it also offered GE a way to discuss future engagements.

GE hopes to have three more customers booked by early 2016 to run pilots — or what Brennan refers to as “lightweight proof of concept” — for Predix offerings. GE executives see the pilots as a way to bring customers onto the selling team. “To get anywhere in the oil and gas industry, we need help selling. We need customer voices out in the industry with success stories, or we’re just not going to come to the table with the credibility that we need. So we need to inspire our customers to want to do that.”

Outcome-Based Pricing

Whether a customer buys an aircraft engine or a heavy-duty gas turbine, GE and the customer often arrange a 10- to 15-year contractual services agreement that allows the company to connect to and monitor that machine, perform basic maintenance and diagnostics, and provide fixed-interval repairs. If GE keeps the equipment running at a certain agreed-upon threshold, the company receives a bonus payment. Such outcome-based pricing may also be applied to coverage of non-GE machines.

Moving forward, GE will use a subscription model to commercialize its software, relying less on traditional licensing models. “We believe deeply in subscription models being the future, so we’re trying to build subscriptions that are priced based on the value that they deliver,” says Johnson. “If we’re talking about taking cost out of the service agreement and providing a subscription to an app that has a set of analytics to help do that, then it’s outcome-based.”

Holsey says the pricing model is evolving from a capital expenditure that bundles equipment with service and software to an operational expense model. “We’ve got some customers that don’t ever want to actually buy the equipment. They just want us to come out and get paid based on production. It’s a service contract that wraps up equipment, services, software, and all the analytics,” says Holsey. He thinks it represents GE putting its money where its mouth is. “If we improve, say, their power consumption by X, we get $1; by Y, we get $1.50,” he says, noting that customers are becoming more open to this type of arrangement and to sharing the data necessary to establish the baseline measurements that makes the model work. “In order for us to leverage the analytics, customers are asking us to put a little bit more risk on the table ourselves, and that’s the difference that we’ve seen in the market,” says Holsey.

Where it can get a little muddy is in trying to assign value to what oil and gas operators bring to the table. “With a company like GE, our intellectual property is a very tangible asset for us. You can look at a drawing. You can see a piece of equipment. For an oil and gas operator, their intellectual property is the way they operate. So when they participate in a program like this with GE, we truly respect the fact that they’re giving us insights into their operations, and that’s really their intellectual property,” says GE’s global key account executive for North America Monk.

In agreeing to outcome-based pricing, customers will also need to cede some control to GE. “If we’re going to work with an oil and gas drilling contractor and commit to a certain amount of nonproductive time decrease, then we have to have some contractual agreements with both the driller and the contracting oil company on what levers we can pull. For example, what data do we have access to? What operational influence do we have in terms of calling for scheduled downtime?” says Jeremiah Stone, general manager for GE Digital’s Industrial Data Intelligence business.

Racing to Lead the Industrial Internet

For GE, its big bet on data coincided with widespread investment in the Industrial Internet. Global spending on the Industrial Internet was $20 billion in 2012. Analysts were forecasting that number would reach $514 billion by 2020, creating nearly $1.3 trillion in value. 3

Both traditional information technology and operations technology players might have posed a competitive threat to GE's emerging Industrial Internet business. But GE executives do not worry much about these competitors because, they say, these companies make moves that are highly visible. While acknowledging that big technology stalwarts are very good at analyzing historical data and in areas like artificial intelligence, Brennan adds that the work of connecting and monitoring large volumes of real-time data is not their core strength. GE's manufacturing expertise, he says, is also a source of market advantage especially against traditional IT companies that try to adapt their enterprise IT software to a heavy-industrial operations technology environment.

What Haynes-Gaspar does lose sleep over, though, are the nimble Silicon Valley startups that are creeping into the space — and have the full attention of venture capital firms. One such example is a startup that offers cloud-based production optimization solutions for the oil and gas industry. “These guys came to talk to us and they had just graduated with PhDs in advanced mathematics from Stanford and they told us, ‘You’re big GE. Why don’t you let us take the data and the analytics, and you guys can be the equipment guys.’ The hubris was breathtaking, but their company was valued for $100 million a year later,” says Haynes-Gaspar. They may not have GE’s billion dollars, but they received millions in round A funding, which, “focused in the right way, could get them market share fast,” she says. Indeed, more than $1.6 billion in venture capital has been pumped into the Internet of Things space, specifically to capitalize on software, data, and analytics opportunities. “It keeps me up at night, too,” says Brennan.

Despite GE’s $1 billion investment in the Industrial Internet, the company won’t be going it alone and wants to partner with startups. “We can’t do everything ourselves, nor should we. There are things that we need to be unapologetically awesome at, and there are areas where we need to partner,” says Haynes-Gaspar. GE wants to be “unapologetically awesome” at data and analytics. “That’s where we’re making our organic investment.” She cites oil and gas market and trading systems as an example of a space where GE does not have domain knowledge and therefore prefers to partner with companies that do. GE intends to build up a large base of partners and together create a robust ecosystem capable of managing every facet of an oil and gas operator’s operation through Predix. “That’s the vision,” says Haynes-Gaspar.

GE also has one very significant advantage over the startups: deep, established relationships with virtually every major industrial company in its competitors’ crosshairs. “Yes, in the past we may have been perceived as big and slow. We may not have had the same reputation as nimble startups out here in Silicon Valley, but we’ve got access to customers,” says Brennan. “With the establishment of GE Digital, we now have access to resources at a scale that will allow us to speed innovation around our customers’ biggest problems. We believe this combination of speed and customer access is one that our competitors won’t be able to touch.”

Simonelli says GE’s days of being seen solely as an equipment provider are drawing short: “Software puts us at the table as a true partner at the heart of the discussion around outcomes our customers are trying to deliver. We will be there for the entire life cycle of a project and solution for 20 to 30 years.”

Undoubtedly, as GE brings more and more of its customers’ data under its management, new kinds of business models will be developed. “Instead of assets under management, the new metrics will become data under management,” says Stone. He envisions a future similar to the one taken by GE’s commercial financing teams. “They actually created a pipeline for the equipment businesses, by virtue of the capital business. We think Predix can play that role as well as we demonstrate the value of a digital industrial approach.”

“The race is on,” Schmid says, admitting that, realistically, GE is taking its initial steps on a very long road. “First, GE needs to be seen as a leader in the industrial enterprise software space.” GE executives believe the company can follow in Google’s footsteps and become the entrenched, established platform player for the Industrial Internet — and in less than the 10 years it took Google to reach that status. “I think that our investment appetite combined with the lessons that we’ve learned on the consumer side, we ought to do it in less time, but that’s a journey that we’re on. First we have to continue on our path to being a great application provider,” says Brennan.

GE’s Calculated Bet on Analytics

Sam Ransbotham

By now, the imminent onset of the Internet of Things isn’t a “dark horse” anymore. Nor is it a mystery that one of the biggest players in the emerging IoT game is GE . But most people aren’t just wondering whether GE’s IoT gamble will pan out in the end — they’re also wondering what playing a similar hand might mean for their organization. Fortunately, GE’s “big bet” gives us insight into four transitions stemming from the soon-to-be ubiquitous stream of IoT data.

Transition #1: The transition from reactive to proactive. The standard mantra of IoT goes like this: With countless of interdependent parts, something is bound to break, fail, or decrease in performance — whether it’s an oil refinery, a jet engine, or a small patch of material within miles upon miles of natural gas or oil pipeline, there is no question in anyone’s mind that entropy or the environment will somewhere create a breakdown in the system. The IoT’s ultimate raison d’être — one that GE is investing in heavily — is to give everyone a heads up on what specific thing will break and when its performance will sag, so that those who make repairs can be in the right place at the right time to avoid an Aliso Canyon-type equipment failure that leads to a natural, economic, and public health disaster .

The concept of anticipating isn’t new; organizations have long prepared for problems by preordering parts according to an average life expectancy, servicing equipment at routine intervals, or locating repair stations so that average response time is low. But GE’s work with sensor data underscores the depth of evidence that can bolster companies’ preparation as well as the breadth of interconnected organizations that can benefit from it — and those are the new factors that IoT allows. In the case, this depth and breadth let GE and others know the ways in which specific pieces of equipment and machines are not average, profiting by being precisely prepared for (or even preventing) adverse events — meaning, they spend exactly the time and resources needed to address them, no more and no less, in contrast to the outlays made by other organizations expensively over-preparing or cleaning up after a disastrous equipment failure.

Transition #2: Analytics helps organizations transition from myopic to holistic. GE knows that, best case, their equipment is a small fraction of the total equipment at a site, yet all of these other components work together with GE’s components. As processing, storage, and communication costs continue their relentless decline, it is feasible to gather data on more and more equipment. Combining data from more equipment lets GE help their customers avoid analytical myopia , where pursuit of isolated gains can distract from the bigger picture. For GE, this holistic approach prompted them to work to integrate data from multiple customers — even competitors’ machines. Unsurprisingly, GE has struggled with this step, as everyone loves the idea of benefiting from everyone else’s data, but is far less excited about sharing their own — a tragedy of the commons . The potential is there, but incentives are not well aligned.

Transition #3: Analytics helps organizations transition from physical to digital. GE has long been known for physical products — lighting, radios, televisions, turbines, industrial automation, motors, locomotives, jet engines, etc. But the company’s big bet on digital is, well, big. Huge, even.

Moving away from a product-centric sales focus is a radical change — and it’s not without risks. Certainly the Predix platform offers GE another way to provide additional value . In GE’s case, a complete switch from atoms (physical) to bits (digital) is unlikely and unnecessary — the optimal solution will likely be a blend, where the physical and digital products create the most value by working together. If it’s done well, GE may create a virtuous cycle of physical and digital lock-in as customers embed GE components not only in their infrastructure, but also their processes. Done poorly, GE may find itself casting aside a century of experience to become just another cloud vendor.

Transition #4: Analytics helps organizations transition from people to machines. As society races to build smarter and smarter machines, not every retiring member of the “aging workforce” will be replaced by another worker, or at least not one doing the same job. This also isn’t new; the type of work people do is always changing. What has changed is the efficacy of ways to capture and codify the “departing knowledge” — which, for GE, starts with capturing vast data. Not all of it will be immediately useable or eliminate the need for workers. However, data and analytics will change the mix of people that GE needs going forward as more and more operational knowledge is embedded into algorithms.

So is GE actually making a “big bet”? Betting involves chance and randomness, and GE’s future in this arena is far from certain — so there is a chance this wager may be lost.

But it isn’t that simple. Betting involves both calculating the stake and assessing the odds.

Consider the stake: In GE’s case, the stake of their bet on data and analytics can’t be measured in isolation. The alternative of not pursuing data and analytics also has a sizeable stake. Refusing to go in this direction may not be a safe alternative, as data from devices has the potential to radically redistribute market power.

Now consider the odds: GE can do (and is doing) a lot to improve their odds of success. Instead of waiting to see how everything turns out, GE is working to minimize uncertainty. This work isn’t dramatic or glamorous. It requires vigilance with data governance, attention to details of massive infrastructure, and adjustments in culture. They show efficacy with small pilots, make a small change, and then show efficacy again. Every small step is work, but it adds up to advantage. In this way, GE is not only making their odds better — it’s also making the potential jackpot bigger. Thus, their IoT strategy is by no means a game of Russian roulette — it’s more like a fast-flowing game of poker.

What can other organizations learn from observing GE’s “big bet”?

First, keep in mind that GE isn’t starting from zero; they have an ace in the hole. They are building digital advantage from competence in complementary physical assets. Other organizations must carefully assess their baseline capabilities to know what their unique advantage might be.

Second, GE has paid their ante to get a seat at this table. The company has a history of exploratory initiatives around analytics that gave them the experience necessary to even consider these transitions. Other organizations must put in the effort required to build basic analytical capabilities.

Third, GE knows their cards, and they are not bluffing. Before putting in their chips, they learned what they were playing for. They learned from existing data about oil platforms to quantify the potential savings from changing unplanned maintenance to planned. They learned from consumer-facing Internet giants but recognized differences in their own context. They learned from using Predix internally to “tightly hone” their own operations before introducing it externally. Other organizations likewise need to learn where data and analytics could make a difference… and where there is less potential.

Sam Ransbotham is an associate professor of information systems at the Carroll School of Management at Boston College and the MIT Sloan Management Review guest editor for the Data and Analytics Big Idea Initiative. He can be reached at [email protected] and on Twitter at @ransbotham.

About the Author

Laura Winig is a contributing editor to MIT Sloan Management Review .

1. Predix is a trademark of General Electric Company.

2. M. LaWell, “Building the Industrial Internet With GE,” IndustryWeek, October 5, 2015.

3. D. Floyer, “Defining and Sizing the Industrial Internet,” June 27, 2013, http://wikibon.org.

i. S. Higginbotham, “BP Teams Up With GE to Make Its Oil Wells Smart,” Fortune, July 8, 2015.

More Like This

Add a comment cancel reply.

You must sign in to post a comment. First time here? Sign up for a free account : Comment on articles and get access to many more articles.

Comment (1)

- In-Building Tech

- Telco Cloud

- 5G NR Release 17

- Private Networks

- Telco AI Deep Dive

- Cloud RAN Deep Dive

- Sponsored Channels:

- Keysight 5G Solutions

- Qualcomm 5G Insights

- 6G Technology & Testing

- Advertise/Sponsor

- Editorial Calendar

- 5G Talent Talk

- Wireless Connectivity to Enable Industry 4.0 for the Middleprise

- Well Technically…

- Will 5G Change the World

- Accelerating Industry 4.0 Digitalization

- White Papers

- Analyst Angle

- Network Infrastructure

- Understanding the 5G Advanced and 6G future

- Rohde & Schwarz 6G Technology & Testing

- Telco Cloud & Edge Forum

Asset performance management: Three IIoT case studies from GE Digital

General Electric reckons the convergence of machines, data and analytics will contribute $10 to $15 trillion to global GDP in efficiency gains over the next two decades. It has spent at least $1 billion to develop its own Predix platform, like an industrial internet of things (IIoT) operating system, to capture a share?of this ?fourth industrial revolution.?

On stage, at IoT World Europe in London this week, Deborah Sherry, senior vice president and chief commercial officer of the company?s GE Digital division, established for the Predix platform and industrial change, presented three case studies to show how the market is already delivering efficiency savings and productivity gains. Here?s the detail.

SIG | ASSET MAINTENANCE IN FOOD AND BEVERAGES

?It has 2,500 machines around the globe, and every one has a unique maintenance plan. It wanted to better maintain machines at scale and at lower cost ? from very beginning of the process, at the packaging and filling, through to the end, when the goods are being shipped out on pallets,? explains Sherry. The initial SIG deployment goes live in July 2018; global rollout starts in January 2019. The pair will develop packaging solutions and technologies to address the industry?s two biggest needs: asset performance and service delivery.

By collecting and analysing asset data, GE Digital will enable SIG to tap into ?billions of data points? from across its operations in real time on its Predix platform. SIG and its customers will move beyond traditional asset monitoring and predictive service models to ?reimagine? their supply chain, enhance quality control and evolve their portfolio, it says.

?It?s not just about the machines themselves; the goal is also to standardise and optimise maintenance and field services. SIG provides these big machines, and the maintenance as well; it has field service engineers going out to these 400 factories,? explains Sherry. SIG gets paid partly on uptime, she notes. There is a domino effect when a machine goes down at the top of the supply chain. ?Maintaining machines before they break down to improve uptime is critical,? says Sherry.

The combination of the APM and FSM applications on Predix in novel, she suggests. ?For the first time, ever, anywhere in the world, SIG and GE Digital are launching an integrated product with asset performance management and field service management capabilities, and bringing it to market.?

She adds: ?It?s enabling SIG to transform ahead of the competition; it is breaking new ground, and leaping ahead of its competitors.?

DB CARGO | ASSET MAINTENANCE IN RAIL AND FREIGHT

DB Cargo trains haul everything from raw resources like coal to finished products like cars. But like all rail traffic, they sometimes run into delays, and trains become stuck on the track. ?That is an expensive problem, because a broken-down train causes problems down the value line, for customers to meet their demand,? says Sherry.

The challenge is to improve maintenance and uptime. ?Most modern rail freight operators, like most of the world frankly, still runs maintenance on a rotor, driven by mileage or time rather than the actual condition of the parts ? and regardless of their condition. They are doing preventative maintenance, whether it is needed or not,? explains Sherry.

DC Cargo trains will transfer information via GSM modules, also retro-fitted, to a shoebox-sized telematics box in the back of the driver?s dashboard, and onwards every few seconds to a control centre at DB Cargo?s head office in Frankfurt, Germany, popping up on screens at one of the dozen-or-so maintenance depots across Europe.

Technicians can then analyse the data to predict when components such as the brakes or the water tank might need maintenance. The solution makes the same play of GE?s asset performance management (APM) software, running in its Predix platform, as the SIG model.

?We are analysing the terabytes of data from all these locomotive to ensure they?re improving uptime, to ensure we are predicting what maintenance they need ? based on the actual condition of the engine, so the right engineer goes out before the engine breaks down, which saves costs and improves the experience,? says Sherry.

Cameras are being fitted to the bottom of trains as well to monitor the condition of tracks.

SCHINDLER | ASSET MAINTENANCE IN ELEVATORS AND ESCALATORS

For Schindler, one of the biggest costs, besides the manufacturing, is maintenance, says Sherry. ?Schindler moves a billion people every day. The health of its assets, and management of their maintenance, is critical,? she explains, telling the story of a stuck elevator in a high-rise on a Friday night. ?It?s not a good scenario if an engineer can?t come out until Monday. You can?t be stuck in elevator without food and water. That can?t happen.?

As it stands, lift companies typically work a service model based on an engineer being available within 15 minutes of every elevator, everywhere in the world. Lift engineers, with highly specialised knowledge, might command salaries of ?150,000 per year, says Sherry. GE Digital has deployed additional sensors in Schindler ?elevators and escalators? to create the so-called ?ee-IoT?, to pre-empt deterioration and failures. ?The company is lowering costs dramatically,? says Sherry.

In addition, Schindler is selling its data, about footfall on its lifts and stairways, to the owners and managers of buildings, notably shopping malls. ?They know which areas of the mall have the most traffic, so the data is valuable to optimise the rents that are charge; they can know which is the most valuable property,? explains Sherry.

She adds: ?Together we have achieved a great reduction of service values, improved fleet availability on time, and this is at heart of why you digitise an asset, because it improves your asset uptime. And this approach doesn?t just apply to trains, but to many industrial sectors.?

- asset performance management

- Deborah Sherry

- field services management

ABOUT AUTHOR

RELATED POSTS

Ai solution for food, chemical industries promises deeper insights, bigger savings, regret, but no surprise – the market responds to the demise of ge digital, time is right for industrial-scale digital transformation, say ge digital and verizon.

Since 1982, RCR Wireless News has been providing wireless and mobile industry news, insights, and analysis to mobile and wireless industry professionals, decision makers, policy makers, analyst and investors.

© 2021-2022 RCR Wireless News

- About RCR Wireless News

- Wireless News Archive

Fill in the form below so we can explore ways to reach your goals or call us at 1800 577 346 .

Leave your details below and we'll be in touch.

Case Study: How General Electric Saved 80% in Development Costs

Think your organisation is too big, bureaucratic and over-regulated to apply lean startup ?

Think again.

Introducing the General Electric Case Study:

General Electric , with its $493B in assets and 200,000 employees worldwide, is doing exactly that. And it’s exactly this kind of progressive thinking, entrenched in GE’s DNA, that sees the company enter its 125th year in a commanding position, ranking eighth in the 2015 Fortune 500 list .

With one third of listed companies facing de-listing in the next five years , it’s no wonder that GE is looking to change the way it thinks, makes decisions and delivers outcomes, in order to keep up with the rapid pace of change disrupting every industry.

GE is fast becoming a model of how to implement lean startup in a large organisation.

Eric Ries, author of the Lean Startup , a new solution development methodology that has radically transformed the way startups get products to market, approached GE with a simple question, after introducing a group of stakeholders to the philosophy that was rooted in software development.

“Is this something you can use to make things like turbines and jet engines, as well?”

Rather than simply shoot down Eric’s question, GE got testing. They put together several new product introduction (NPI) teams at Crotonville, the company’s leadership institute. Eric was brought in and taught the teams how to apply the methodology.

When asked whether this was something that was applicable to their respective businesses, the resounding response was “yes”.

As soon as team members returned to their respective business units, their ideas and new ways of working were quickly squashed. They realised that applying lean startup would not only require training but a cultural shift in the organisation.

GE promptly created its Fastworks program - geared towards the successful adoption and use of lean startup philosophy across GE.

Step one? Get senior leaders, “the top 5,000”, trained and educated in lean startup. This formed part of a roadshow that Fastworks’ co-founders and partners Viv Goldstein (Business Innovation) and Janice Semper (Human Resources) embarked upon, together with Eric Ries and David Kidder (author of The Startup Playbook ). You’ll note that the partners together represent methodology and culture, not just one or the other.

The Fastworks team spent 2 days with senior leaders teaching them all about lean startup and this was not without its challenges. Many senior leaders have spent years at GE and most grew up with Six Sigma and as such were process driven, perfectionist and anti-variation. The lean startup sessions were as much as about challenging them to think in a different way as much as they were about lean startup methodology.

Getting Buy-In from Senior Management

Because of the structural hierarchy of GE, getting senior stakeholder buy in was critical to the success of the program. Getting support at purely a grassroots level wouldn’t be enough to get traction.

However, recognising the benefits that grassroots employees could bring by way of testing projects and gathering proof points, they could take these validated learnings as ‘money in the bank’, so to speak, and say “here is the impact, here is the evidence” to obtain real and ongoing support from senior stakeholders.

They quickly realised that Eric Ries is just one person and that they needed to bring the expertise in-house. As such, GE created a community of coaches and trained them to build the expertise internally.

Was there a specific plan to train ‘X’ amount of teams and coaches? No, GE essentially applied the lean startup principles to its rollout of this program.

“Let’s start small, learn and build it up from there” says Semper.

GE’s different businesses own Fastworks, as opposed to it being a top down corporate initiative, which supports buy in. They are given a framework but are allowed to determine how many coaches, who becomes a coach, whether it’s a part time or full-time role and so on.

“Here’s the framework - it’s up to you how you want to own it.”

While this was initially uncomfortable for a lot of people because it requires judgment, it also gives them ownership, critical to buy-in.

They’ve found that both part time and full time coaches can work in varying degrees.

What about non-tech companies?

“This absolutely works outside of technology and software and GE is a great proof point for that”, having applied the philosophy in areas such as transportation, energy and finance.

It’s not just about training people “What we learned at Crotonville early on is that as soon as people went back to their business they struggled to use the methodology”, says Semper. “You need to think more broadly about your organisation and the ability to make sure that behaviours and culture can support the application of a lean startup approach.”

Questions to ask:

- will lean startup behaviours be permissible and rewarded?

- does performance management support lean startup?

- what are your expectations of your leaders in supporting lean startup?

- what competencies do you need to develop ?

- like health and fitness, a holistic approach is required to successfully implement lean startup - a personal trainer is pointless if your house is full of high carb, sugary temptations

Everything must be aligned with this way of working

At GE, limiting characteristics that embody the values of its people are failure not being an option, an addiction to being right and a lack of customer-centricity and empathy when developing new products. Why engage customers when you have all the answers right?

Semper zeroed in on these cultural challenges and started to attack them by creating a new belief system that aligned with the Fastworks and lean startup principles.

This belief system was summarised by the following:

- empower and inspire each other

- customers determine our success

- stay lean to go fast

- learn and adapt to win

- deliver results in an uncertain world

This was supported by senior management projecting to their people that “this is what we believe”.

New beliefs underpin new behaviours and these new behaviours are critical to the success of lean startup in a large organisation.

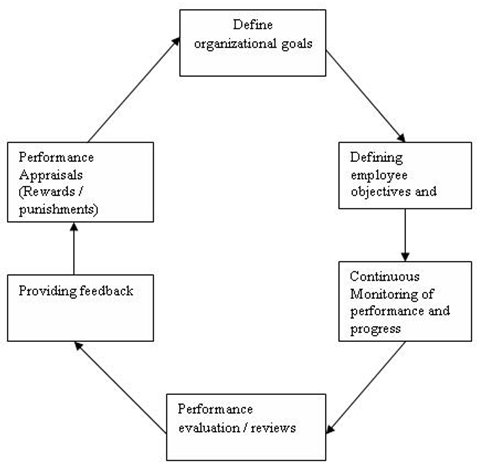

Performance management system was out of synch

GE’s performance management system was representative of your standard run of the mill linear system. The type where goals are set and reviewed once a year. In order to support the very experimentation and adaptability that lean startup advocates, the performance system had to also embody these values. GE is currently moving towards a more adaptable system where ongoing management is stressed over once a year check-ins.

Still, there are challenges as one would expect of a company the size and scale of GE - 200,000 diverse employees across 175 countries.

But the results speak for themselves...

ADVERTISEMENT

Transport: Using lean startup, GE developed and commercialised a new engine based on regulatory changes brought on by the EPA. It got to market 2 years before its competition not only resulting in significant cost savings, but bettering the EPA’s requirements. This positioned them extremely well with customers, gave them first mover advantage.

Energy: GE developed a gas turbine which enabled it to deliver the most efficient, low cost energy solution it could to customers and it decreased development costs by 60% by doing so!

In its Industrial business GE:

- reduced time of NPI by two thirds

- reduced time to customer validation by 80%

The latter not only represents a significant cost saving but also frees up NPI funds to reinvest into new ventures, rather than over-invest building the wrong thing and scrambling to find budget for new projects. This snowball effect enables GE to explore a much higher number of new innovations and products in a much shorter time-frame with much lower expense.

Positive Impact on Employee Morale

In a time when customer churn can cost organisations more than $50,000 per person , improving employee engagement and therefore retention is also top of the agenda for most HR managers. Implementing lean startup means that employees are engaged on projects that are delivered quicker and actually realise benefits. This is light years away from traditional, waterfall based ‘transformational’ projects.

Funding Process

The Fastworks process has been embedded into operations.

If an employee has an idea they add it to a growth board and seek seed funding to validate their idea. If validated, then the employee qualifies for additional funding. If invalidated, then things simply stop (stopping anything at GE is also something that was counter-cultural before lean startup reared its head). Now, if a customer says that a new product or feature wouldn’t create value for them, the project isn’t pursued. Makes sense, in retrospect.

On Regulation

I often hear leaders from regulated organisations say that “it’s impossible for us to implement lean startup - it’s too risky, we’re so regulated.”

The fact is that lean startup is a de-risker.

The cost to go to market with a regulated product is higher than normal, given the compliance requirements and checks that need to take place.

“Using lean startup allows us to mitigate risk before putting things to market - it is a risk mitigant that applies across our healthcare, transportation, finance businesses (and so on)”.

By testing quickly, we are taking lots of small bets rather than few large ones and only going to the regulator with products that we know our customers have an appetite for.

Australian health insurer Medibank tested appetite for its Gym Better product by sending employees out to a busy shopping strip in plain clothes with iPads trying to sell a fictional product under the guise of a fictional company to passerbyers and gym goers, purely to gauge customer interest. If somebody wanted to buy on the spot they were simply reminded that “sorry, this doesn’t actually exist but thanks for your cooperation - here’s two movie tickets!”

This approach cost much less than jumping through regulatory hoops and putting a product to market that there is not enough appetite for.