How it works

For Business

Join Mind Tools

Article • 7 min read

PDCA (Plan Do Check Act)

Continually improving, in a methodical way.

By the Mind Tools Content Team

Also known as PDSA, the "Deming Wheel," and "Shewhart Cycle"

Imagine that your customer satisfaction score on a business ratings website has dipped. When you look at recent comments, you see that your customers are complaining about late delivery, and that products are being damaged in transit.

So, you decide to run a small pilot project for a month, using a new supplier to deliver your products to a sample set of customers. And you're pleased to see that the feedback is positive. As a result, you decide to use the new supplier for all your orders in the future.

What you've just done is a single loop called the PDCA Cycle. This is an established tool for achieving continuous improvement in your business.

The PDCA approach was pioneered by Dr William Deming, and we've worked closely with The Deming Institute to produce this article. In it, we outline the key principles of PDCA, and explain when and how to put them into practice.

Click here to view a transcript of this video.

What Is PDCA?

In the 1950s, management consultant Dr William Edwards Deming developed a method of identifying why some products or processes don't work as hoped. His approach has since become a popular strategy tool, used by many different types of organizations. It allows them to formulate theories about what needs to change, and then test them in a "continuous feedback loop."

Deming himself used the concept of Plan-Do- Study -Act (PDSA). He found that the focus on Check is more about the implementation of a change.

He preferred to focus instead on studying the results of any innovations, and to keep looking back at the initial plan. He stressed that the search for new knowledge is always guided by a theory – so you should be as sure as you can that your theory is right! [1]

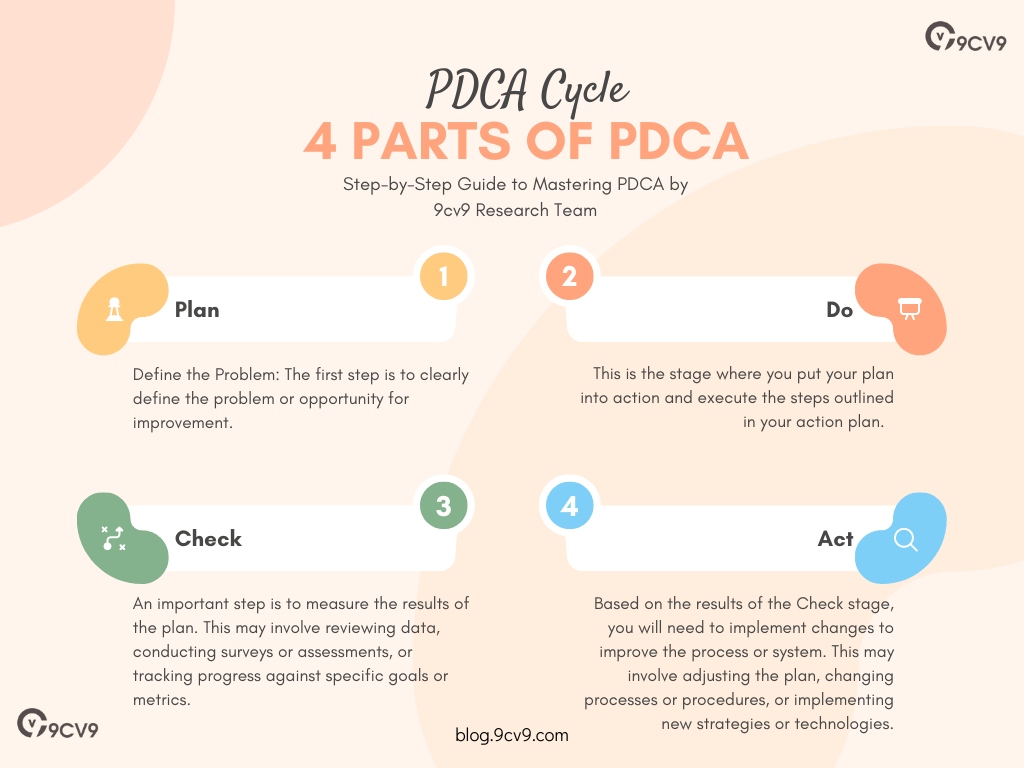

The Four Phases of the PDCA Cycle

With the PDCA cycle you can solve problems and implement solutions in a rigorous, methodical way. Let's look at each of the four stages in turn:

First, identify and understand your problem or opportunity. Perhaps the standard of a finished product isn't high enough, or an aspect of your marketing process should be getting better results.

Explore the information available in full. Generate and screen ideas, and develop a robust implementation plan.

Be sure to state your success criteria and make them as measurable as possible. You'll return to them later in the Check stage.

Once you've identified a potential solution, test it safely with a small-scale pilot project. This will show whether your proposed changes achieve the desired outcome – with minimal disruption to the rest of your operation if they don't. For example, you could organize a trial within a department, in a limited geographical area, or with a particular demographic.

As you run the pilot project, gather data to show whether the change has worked or not. You'll use this in the next stage.

Next, analyze your pilot project's results against the criteria that you defined in Step 1, to assess whether your idea was a success.

If it wasn't, return to Step 1. If it was, advance to Step 4.

You may decide to try out more changes, and repeat the Do and Check phases. But if your original plan definitely isn't working, you'll need to return to Step 1.

This is where you implement your solution. But remember that PDCA/PDSA is a loop, not a process with a beginning and end. Your improved process or product becomes the new baseline, but you continue to look for ways to make it even better.

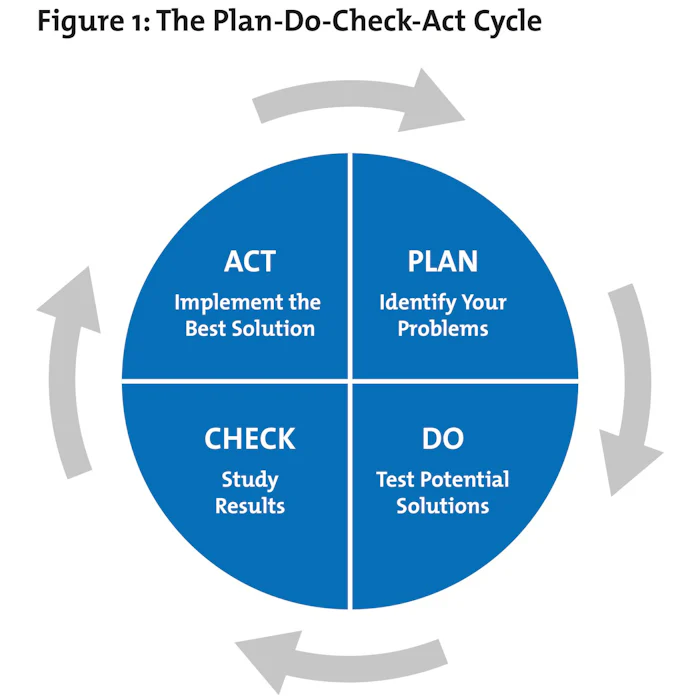

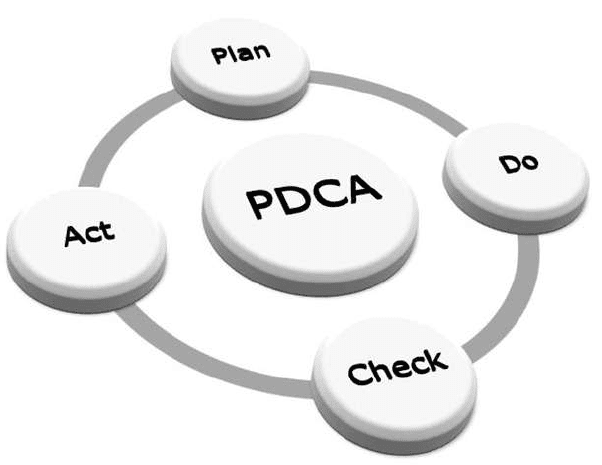

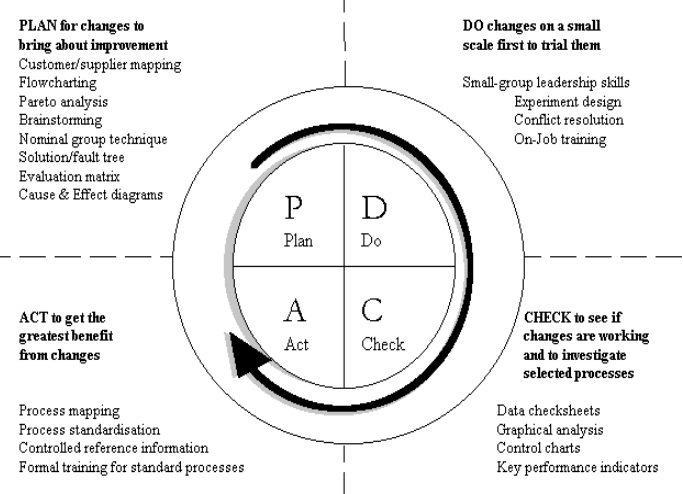

The four stages of the cycle are illustrated in Figure 1, below:

PDCA Model courtesy of The W. Edwards Deming Institute®.

When to Use PDCA

The PDCA/PDSA framework works well in all types of organizations. It can be used to improve any process or product, by breaking them down into smaller steps or development stages, and exploring ways to improve each one.

It's particularly helpful for implementing Total Quality Management or Six Sigma initiatives, and for improving business processes generally.

However, going through the PDCA/PDSA cycle can be much slower than a straightforward, "gung ho" implementation. So, it might not be the appropriate approach for dealing with an urgent problem.

It also requires significant buy-in from team members, and offers fewer opportunities for radical innovation – which may be what your organization needs instead.

How to Use PDCA to Improve Personal Performance

While PDCA/PDSA is an effective business tool, you can also use it to improve your own performance:

First, Plan: Identify what's holding you back personally, and how you want to progress. Look at the root causes of any issues, and set goals to overcome these obstacles.

Next, Do: When you've decided on your course of action, safely test different ways of getting the results that you want.

Then, Check: Review your progress regularly, adjust your behavior accordingly, and consider the consequences of your actions.

Finally, Act: Implement what's working, continually refine what isn't, and carry on the cycle of continuous improvement.

The PDCA/PDSA cycle is a continuous loop of planning, doing, checking (or studying), and acting. It provides a simple and effective approach for solving problems and managing change. The model is useful for testing improvement measures on a small scale before updating procedures and working practices.

The approach begins with a Planning phase in which problems are clearly identified and understood, and a theory for improvement is defined. Potential solutions are tested on a small scale in the Do phase, and the outcome is then studied and Checked.

Go through the Do and Check stages as many times as necessary before the full, polished solution is implemented, in the Act phase of the cycle.

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Book Insights

Simply Effective: How to Cut Through Complexity in Your Organization and Get Things Done

Ron Ashkenas

How To Use Informal Coaching

A Guided Scenario Can Bring Informal Coaching to Life.

Add comment

Comments (0)

Be the first to comment!

Get 20% off your first year of Mind Tools

Our on-demand e-learning resources let you learn at your own pace, fitting seamlessly into your busy workday. Join today and save with our limited time offer!

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

Pain Points Podcast - Balancing Work And Kids

Pain Points Podcast - Improving Culture

Mind Tools Store

About Mind Tools Content

Discover something new today

Pain points podcast - what is ai.

Exploring Artificial Intelligence

Pain Points Podcast - How Do I Get Organized?

It's Time to Get Yourself Sorted!

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

The t-shaped management model.

Looking at the T-Shaped Model Which Brings a New Concept to Knowledge Management

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Team Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

The PDCA Cycle (30+ Plan Do Check Act Examples)

In today's busy world, everyone is looking for simple ways to do things better and faster. Enter the PDCA cycle. It's like a four-step dance for making things work smoothly.

The PDCA cycle is an improvement cycle that involves four steps: Plan, Do, Check, and Act, to help improve any business process or task.

If you want to make your work more organized or solve problems more efficiently, the PDCA cycle can be your go-to tool.

Introduction to the PDCA Cycle

The PDCA cycle is a tool that helps with project planning. It breaks down a process into manageable steps, helps you test them, and adjust to get better results.

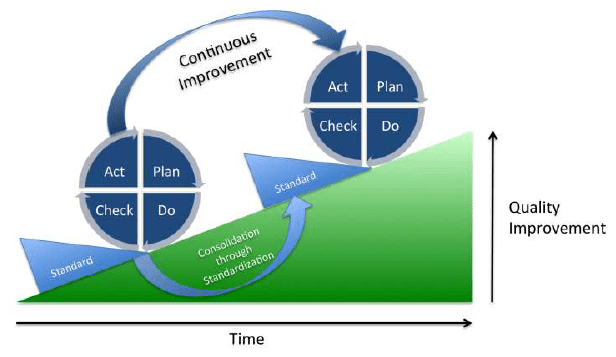

The cyclical nature of PDCA is a simple guide to help groups and companies work better and keep improving.

It's not just a one-time thing. This PDCA model is like a circle that keeps going, helping you learn and grow. By going through the steps again and again, you can stay up to date and keep making things better.

Even though it started in factories with quality control, the PDCA cycle is now used everywhere—in hospitals, schools, tech companies, and even for personal goals. It's easy to use, and you don't need special training or tools. You just need to be ready to try new things and keep improving.

Brief History of PDCA

The origins of the PDCA cycle trace back to the early 20th century. A man named Walter Shewhart , often called the 'father of statistical quality control,' introduced the idea.

Shewhart was working in the world of manufacturing, seeking ways to make production more efficient and error-free. Remember, this was a time when factories were booming, and any way to save time or reduce mistakes was super important.

Building on Shewhart's thoughts, Dr. W. Edwards Deming further used the plan do check act cycle for something new in the mid-1900s.

Deming's work specifically dealt with rebuilding Japan's industry after World War II . He realized that for industries to succeed, they needed a simple and strong framework. And he favored the PDCA cycle as a means of problem solving and continuous improvement.

It's because of these two people who helped create the process that it's sometimes called the Deming Cycle, Deming Wheel, or Shewhart Cycle.

So, why should you care about this history? Because understanding where the PDCA cycle came from helps in appreciating its value. It's not just a trendy buzzword; it's a tested and proven method that's been helping businesses for almost a century.

4 Steps of the Plan Do Check Act Cycle

Simply put, the four stages or steps are: Plan, Do, Check, Act. In a way, this is project management plan that not only improves management practices but also eliminates ineffective elements.

This is the planning stage—the time you think and plan. You find a problem or a chance to do something and decide what you want to achieve. Basically, you set up project goals and potential solutions to business problems.

Now, it's action time. Do the plan you laid out in the previous stage. But don't just rush in! It's important to do this on a smaller scale first, like a pilot test. Consider it a 'trial run'. This way, you get to see how things work without fully committing.

After you've taken action, you pause and assess. You're looking back at the results of your 'Do' phase. Did it go as planned? Were there unforeseen hiccups? This is your moment of reflection. Remember, there are problably multiple solutions to any problem, so if this plan didn't work, you can try a new one.

Sometimes this method is called plan do study act, instead of plan do check act. So you can think of this as the time to study the data.

After looking at the results from the 'Check' step, you make changes. If things worked, you can do more of it. If not, you fix and improve. After making changes, you start the cycle again with 'Plan'.

In essence, the PDCA cycle is an ongoing journey of improvement. It's all about learning, repeating, and progressing.

The Importance of Continuous Improvement

The heart of the PDCA cycle lies in the principle of continuous improvement . In today's ever-evolving world, standing still is not an option. You either move forward, or you risk falling behind.

Continuous improvement isn't about chasing perfection. It's about the journey of getting better every day. It’s acknowledging that no matter how good a process or product is, there's always room to do better.

Here’s why it is crucial to continuously improve:

1. Adapting to Change : Just like seasons change, so do markets, customer preferences, and technologies. By continuously improving, you ensure that you're not left behind.

2. Efficiency and Productivity : Improving business processes means eliminating wastes and unnecessary steps. This results in faster outputs with fewer resources.

3. Employee Satisfaction : Believe it or not, people like being part of a system that gets better. It boosts morale and engagement. When employees see their feedback being used to make positive changes, they feel valued and involved.

4. Customer Satisfaction : Continuously improved products or services translate to happier customers. By showing that you’re committed to betterment, you not only keep loyal customers but also attract new ones.

5. Long-Term Success : Think of continuous improvement as investing in the future. Small enhancements today can lead to significant benefits in the long run.

Use-Cases of the PDCA Cycle

Let's shift our gaze from the theory of PDCA to its real-world applications. The plan do check act cycle is not limited to big businesses or specific industries; it can be used by anyone who wants to continuously improve processes.

In hospitals, patient care is the most important. By using the PDCA cycle, hospitals can make patient admissions easier, improve treatment plans, and perform better after-care procedures.

For example, if a hospital notices long wait times in the emergency room, they can Plan a strategy to make it better, Do a trial run with the new system, Check the results, and then Act to put the plan into place everywhere or change it based on the feedback from the trial run.

Schools and colleges are always looking for ways to improve student learning and involvement. The PDCA cycle can help with curriculum design, classroom management, or even in creating better ways for students to give feedback.

A school might notice students struggling with online learning. They can then make a plan to offer additional resources, test it out with a group, assess the results, and change accordingly.

Tech Startups

In the tech world, you need to keep up with changes. Startups can use the PDCA cycle to make better products, improve user experience, or market better.

Think of a new app with problems after it's launched. The company can make a plan to solve it, try the fix, see what users say, and then improve it for the desired outcome.

Personal Goal Setting

Beyond organizations, individuals can use the PDCA cycle for personal development. Whether it's fitness goals, learning a new skill, or financial planning, this cycle can be a guide.

Suppose you set a goal to read more books. You plan by setting aside time each day, try it out for a week, check if you're consistent, and then adjust based on challenges or insights.

Manufacturing

PDCA started in factories, and they can gain a lot from it. It can help improve products and make production faster.

If a factory finds more faulty products, they can use the PDCA cycle to find the problem, try fixes, see what works, and then use the best solution regularly.

Starting Your Own PDCA Cycle: Step-by-Step Guide

Let's walk through how you can start your own PDCA journey.

1. Identify a Challenge or Opportunity : Every journey begins with a destination in mind. Look for an area in your organization, project, or personal life that needs improvement or has potential for growth. It could be as simple as improving morning routines or as complex as recreating a product line.

2. Gather Data : Arm yourself with information. Understanding the current situation helps in setting realistic goals. If sales have dropped in your business, get numbers. How much? Since when? Any patterns?

3. Set Clear Objectives : Define what success looks like. If you're addressing the sales drop, decide on a target percentage increase. Be specific. Instead of saying "increase sales," aim for "increase sales by 10% in the next quarter."

4. Brainstorm Solutions : Think of strategies to meet your objective. If it's about sales, maybe you need better marketing, more training for the sales team, or even a new product feature.

5. Pilot Test : Remember the importance of the 'Do' phase being a trial run? Implement your solution, but start small. This reduces risks. Using our sales example, maybe first train a small sales team with a new technique and see how it works.

6. Evaluate Results : Once your pilot is done, check the outcomes. Did sales improve for the team that received new training? By how much? Were there any challenges?

7. Implement or Adjust : Based on your evaluation, take action and implement change yourself. If the new sales training worked well, roll it out for everyone. If not, revisit your strategies, adjust, and test again. This is the act phase.

8. Document Everything : Keep a record of your entire PDCA process. This not only helps in future cycles but also creates a way for your team to look at what worked, what didn't, and make incremental changes in their process improvement.

9. Loop Back : The PDCA cycle isn’t a one-time thing. After 'Act', circle back to 'Plan'. Maybe after addressing sales, the next cycle focuses on having your customers came back again and again.

10. Celebrate and Reflect : Lastly, every time you complete a cycle, take a moment to acknowledge the progress. Celebrate wins, no matter how small. And always reflect on lessons learned for future cycles.

Common Mistakes and How to Avoid Them

The Shewhart cycle is an iterative process. In other words, it's a continuous process improvement.

But, just as a juggler learns best from dropped balls, understanding common mistakes in the PDCA cycle can prepare you to avoid or address them before they happen.

1. Skipping the Planning Phase : In eagerness to act, it's tempting to jump straight into action. But remember, a house built on shaky foundation won't stand for long.

Strategy : Always invest time in thorough planning. This phase sets the tone for the entire cycle.

2. Ignoring Data : Operating on gut feelings or assumptions can lead you down the wrong path. The PDCA cycle relies on data-driven decisions.

Strategy : Consistently gather relevant information. Then analyze it. Let numbers guide your actions.

3. Setting Vague Objectives : Broad goals like "improve customer service" lack direction. Instead, be specific in your initial plan.

Strategy : Always aim for SMART (Specific, Measurable, Achievable, Relevant, Time-bound) objectives. Instead of "improve customer service," aim for "reduce customer complaints by 15% in the next two months."

4. Neglecting the 'Check' Phase : It's easy to move from action to adjustments without pausing. But without assessment, you might miss valuable insights.

Think of it like the scientific method, where you have a controlled environment and by looking at the success criteria you can make sure you avoid recurring mistakes.

Strategy : Always allocate time to evaluate results. It's this reflection that powers informed adjustments.

5. Resisting Change : Sometimes, looking at the data will show a need for significant changes. Resistance can slow or stop progress.

Strategy : Cultivate a growth mindset . Embrace changes as opportunities to learn and grow.

6. Stopping After One Cycle : Viewing the PDCA cycle as a one-off can limit its benefits. Remember, it's about continuous improvement.

Strategy : Always loop back. Each cycle offers a chance to refine further.

7. Working in Silos : Keeping the PDCA process in only one department or individual can limit its scope and effectiveness.

Strategy : Promote collaboration. Encourage cross-departmental input and feedback.

8. Fearing Failures : Not every cycle will lead to positive results. Fear of failures can slow innovation and risk-taking.

Strategy : Reframe failures as learning opportunities. Every setback is a setup for a better comeback.

9. Neglecting Documentation : Forgetting to record your processes and outcomes can lead to repeated mistakes.

Strategy : Maintain a detailed log of every PDCA cycle. This becomes a reference point for the next stage.

10. Overcomplicating the Process : The PDCA cycle is inherently simple. Overloading it with complexities can reduce its effectiveness.

Strategy : Stick to the basics. Keep the cycle streamlined and straightforward.

Pros and Cons of the PDCA Cycle

While the PDCA cycle has many benefits, it's important to be aware of its limitations too. Let's weigh both sides of this coin to give you an more rounded view.

Pros of the PDCA Cycle

1. Simplicity : At its core, the PDCA cycle is a straightforward four-step process. This makes it easy to understand, adopt, and communicate across teams.

2. Versatility : Whether it's a multinational corporation or your personal fitness goal, the PDCA cycle can be applied anywhere. Its universality is one of its strongest points.

3. Data-Driven : By relying on data and evaluations, the PDCA cycle reduces guesswork and ensures decisions are supported by hard evidence.

4. Continuous Improvement : The continuous loop promotes regular refinement, ensuring that internal and external processes and strategies are always evolving and improving.

5. Risk Mitigation : By emphasizing small-scale testing in the 'Do' phase, the PDCA cycle helps to identify potential issues or ineffective elements early on, reducing the chances of large-scale failures.

6. Empowers Teams : Since it's a collaborative work process, the PDCA cycle encourages team input and feedback, leading to more inclusive and holistic solutions.

Cons of the PDCA Cycle

1. Time-Consuming : Especially during the initial phases, the PDCA cycle can be time-intensive as teams gather data, plan, and test.

2. Potential for Overanalysis : The 'Check' phase, if not kept in check, can lead to "paralysis by analysis," where teams get too caught up in evaluating data and delay actionable steps.

3. Dependency on Data : While being data-driven is a strength, it can also be a limitation if there's a lack of quality data. Poor data can lead to bad decisions.

4. Requires Commitment : For the PDCA cycle to be effective, it requires consistent commitment from the team. Occasional or half-hearted attempts might not yield good results.

5. Scope for Subjectivity : While the process is data-driven, interpretations of the data can be subjective , leading to potential biases in decisions.

Real-Life Examples of the PDCA in Action

Stories have a way of making concepts stick. With strategic planning, people can reduce costs, have quality improvement, and progress regularly.

Let's step into the real world and explore some stories that show the PDCA cycle making a noticeable difference.

1. A Coffee Shop's Quest for the Perfect Brew : A local coffee shop noticed a dip in their morning sales. Using the PDCA approach, they planned a way for customers to tell them what they want. They then introduced new coffee blends on a trial basis.

After assessing customer feedback and sales data, they found that introducing cold brews and specialty lattes was a hit. The shop adjusted its menu, retrained its baristas, and saw a 20% rise in sales the following month.

2. School Attendance Improvement : A school was finding that students were absent a lot. The management planned a survey to understand the reasons. From the feedback, they introduced a mentorship program and more engaging extra-curricular activities.

After testing these out for a semester, there was a noticeable increase in student attendance. The school then acted by making these changes permanent and continued to monitor attendance rates for further improvements.

3. Tech Firm's Bug Battle : A tech startup's app had a lot of bugs after a major update. The team planned a way for users to report issues. They then put out smaller patches to address the most common problems.

Checking user reviews and bug reports, they realized the need for a more in-depth testing phase before updates. Acting on this, they changed their testing protocols, leading to more stable updates in the future.

4. Personal Fitness Journey : Mike wanted to get in shape. He planned a workout routine and a diet. For the first two weeks, he tested a mix of cardio and weights.

Checking his progress, he realized he enjoyed weight training more and saw better results with it. He then acted by focusing more on strength training and adjusting his diet to support muscle growth. By the full end to end process of three months, Mike had lost 15 pounds and increased his muscle mass.

5. Hospital's Patient Care Boost : A city hospital wanted to make it so patients could leave sooner after treatment. They planned by gathering data on current discharge processes.

They tried to improve processes by bringing a digital system to one department. Using this system, they found that paperwork was processed faster meaning patients could leave sooner. The hospital acted by implementing the digital system hospital-wide.

Frequently Asked Questions (FAQ)

1. What is the PDCA cycle? The PDCA cycle is a four-step method used to improve processes and systems. The steps are Plan, Do, Check, and Act.

2. Where did the PDCA cycle originate? The PDCA cycle has its roots in the early 20th century, introduced by Walter Shewhart and further refined by Dr. W. Edwards Deming.

3. Can the PDCA cycle be used outside of manufacturing? Yes, while it started in manufacturing, today the PDCA cycle is used in various sectors like healthcare, education, tech startups, and even for personal goals.

4. Why is the 'Check' phase crucial in the PDCA cycle? The 'Check' phase involves assessing results. It's essential for understanding what's working and what needs adjustment, ensuring the cycle's effectiveness.

5. What are the main benefits of the PDCA cycle? The PDCA cycle promotes continuous improvement, risk mitigation, data-driven decisions, and inclusivity in feedback and solutions.

6. Are there any common mistakes to avoid when implementing PDCA? Yes, some common mistakes include skipping the planning phase, setting vague objectives, and neglecting the 'Check' phase. It's crucial to be aware of these to make the most of the PDCA cycle.

7. How can I start implementing the PDCA cycle in my organization or personal life? Begin by identifying a challenge or opportunity. Gather data, set clear objectives, and then proceed through the Plan, Do, Check, and Act steps. Remember, it's a continuous cycle, so always loop back to the planning phase after acting.

8. Are there any real-life examples of the PDCA cycle in action? Absolutely! From coffee shops refining their brews to tech startups improving apps based on user feedback, the PDCA cycle has been effectively implemented in various scenarios.

9. How does the PDCA cycle encourage continuous improvement? By its very design, the PDCA cycle promotes revisiting and refining processes. By constantly looping back to the planning phase, it ensures that operations are always evolving based on feedback and results.

We've traveled quite a bit through the world of PDCA, haven't we? From its history to how it works and where it's used, we've covered a lot of ground. Now, let's wrap up what we've learned.

The PDCA cycle is like a step-by-step guide for making things better. Think of it as a map that helps you find better ways to do things. Each step, from planning to acting, helps you get better and learn from any mistakes.

In today's world, things change a lot and fast. That's why having a way to keep improving is super important. The PDCA cycle helps you do just that.

Whether you're in charge of a big company, a small team, or just trying to reach your own goals, the PDCA cycle can help.

Related posts:

- 70+ SMART Goal Examples (For Students, Losing Weight, Saving Money...)

- David Kolb (Psychologist Biography)

- 121+ Strengths Examples for Job Interviews

- 250+ Flirty Bet Ideas (For Couples + Consequences)

- 183+ Opportunities Examples for SWOT Analysis (Huge List)

Reference this article:

About The Author

Free Personality Test

Free Memory Test

Free IQ Test

PracticalPie.com is a participant in the Amazon Associates Program. As an Amazon Associate we earn from qualifying purchases.

Follow Us On:

Youtube Facebook Instagram X/Twitter

Psychology Resources

Developmental

Personality

Relationships

Psychologists

Serial Killers

Psychology Tests

Personality Quiz

Memory Test

Depression test

Type A/B Personality Test

© PracticalPsychology. All rights reserved

Privacy Policy | Terms of Use

Continuous Improvement Toolkit

Effective Tools for Business and Life!

Applying the PDCA Cycle: A Blueprint for Continuous Improvement

- 5 MINUTES READ

Also known as Shewhart Cycle and Deming Wheel.

Variants include PDSA Cycle and OPDCA.

The Plan-Do-Check-Act Cycle (PDCA Cycle) is a four-step model for systematic problem solving and continuous improvement. It offers a simple and structured way for resolving business-related issues and creating positive change . This framework is widely recognized as the basis for enhancing the quality of processes, products, and services by following a logical sequence of four steps: Plan, Do, Check, and Act.

The PDCA cycle model can be applied in most kinds of projects and improvement activities, whether they are breakthrough changes or smaller incremental enhancements. For example, it can be effectively utilized when aiming to enhance employee skill levels within an organization, change the supplier of a product or service, or increase the quality of care and patient engagement within a hospital.

A common practical example of the PDCA cycle can be illustrated when dealing with customer complaints. This scenario involves steps like reviewing, categorizing, and prioritizing the existing complaints, generating potential solutions for addressing the most frequent complaints, conducting pilot surveys with sample customers to test new options, collecting and analyzing customer data and feedback, and ultimately implementing lessons learned on a larger scale. The above steps represent the PDCA cycle in action.

The Four Phases of the PDCA Cycle

The PDCA cycle begins with the Planning phase which involves the identification of the problem and objectives. During this phase, a collaborative effort is made to agrees on the problem to be solved or the process to be improved. Subsequently, an in-depth analysis of the existing as-is situation is conducted, alternative solutions are identified, and the most promising solution is selected and scheduled for implementation.

In the Do phase, the selected solution is put into action on a limited scale. This phase also involves ongoing progress measurement, data collection, and feedback gathering to facilitate subsequent analyses.

The Check phase involves analyzing the collected data and feedback and comparing the outcome against pre-established objectives. This phase allows to evaluate how well the solution has worked and where further enhancement may be needed. Additionally, it involves the identification of unexpected issues and the gathering of key learnings. It is important to note that the Do and Check phases may need to be repeated until the desired results are achieved.

The Act phase is the point at which the chosen solution is fully integrated. This phase requires taking actions based on the insights acquired from the Check phase. A plan for full-scale implementation is carried out, taking into account the associated costs and benefits. The Act phase also concerned with standardizing , documenting, sustaining the improved process, as well as integrating it into the organization’s system.

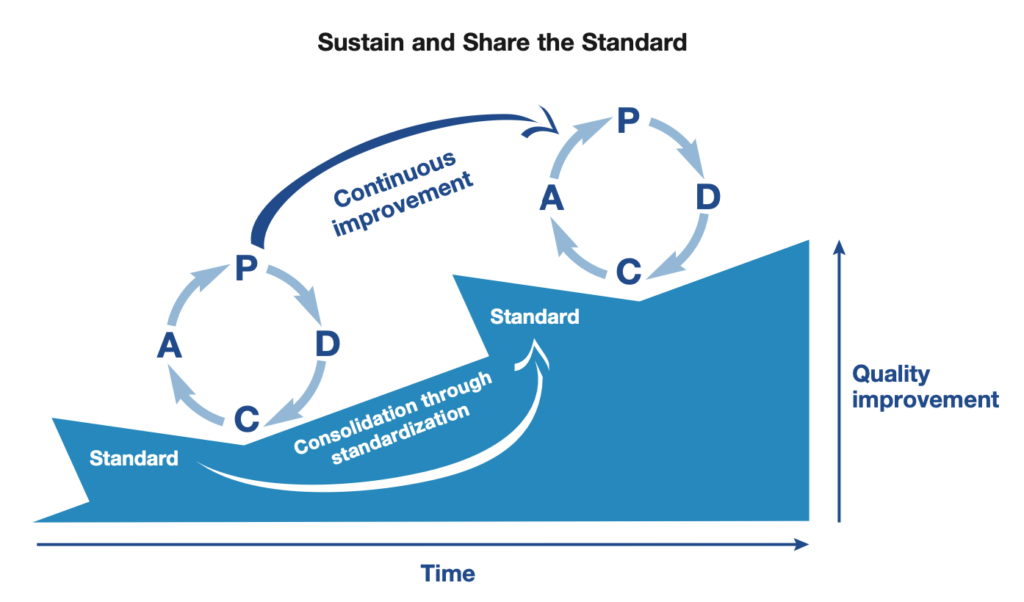

The utilization of the PDCA cycle doesn’t necessarily stop once the Act phase is completed. The improved process often becomes the new baseline, which may prompt a return to the Plan phase. Multiple iterations of the PDCA cycle may be essential for a permanent resolution of the problem and the attainment of the desired future state. Each cycle brings one closer to their goals and extends their knowledge further.

A common example often used to illustrate the PDCA cycle is when a team is initiating a new product development.

Another example is when a lab team is planning to solve a customer complaint about the delayed test results at a laboratory.

In the 1990s, a modified version of the PDCA cycle was introduced. It was called PDSA cycle where ‘S’ stands for Study. It is believed that data analysis is important for any improvement effort, and “Checking” does not really imply studying and analyzing the data.

OPDCA is another version of PDCA where ‘O’ stands for Observe . The Observe is added at the front of the cycle to emphasize the need to observe before creating any plan. The goal of observation is to find out what is really happening and what can be improved.

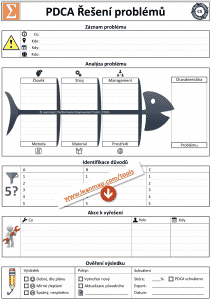

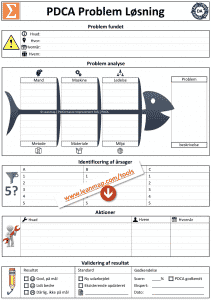

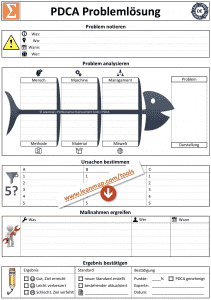

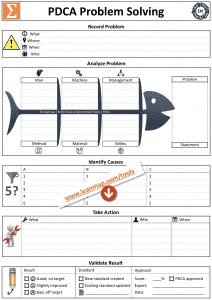

You may find it useful to use the following tools in each phase of the PDCA/PDSA cycle:

- Plan – process mapping , brainstorming, waste analysis , prioritization matrix , improvement roadmap , gap analysis , and force field analysis .

- Do – Gantt chart , dashboard, data collection methods , sampling, observation , check sheet , and control chart.

- Check/Study – graphical analysis , statistical analysis, 5 whys , fishbone diagram , Pareto analysis , root cause analysis, and decision-making techniques .

- Act – process mapping , Gantt chart , dashboard, control chart, control plan, visual management , and standard work .

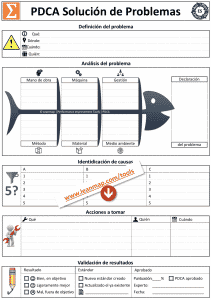

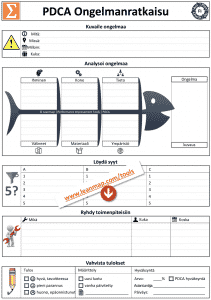

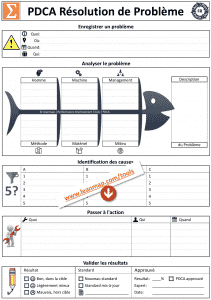

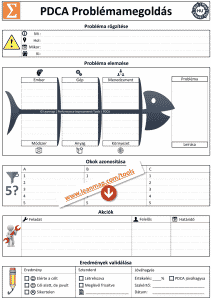

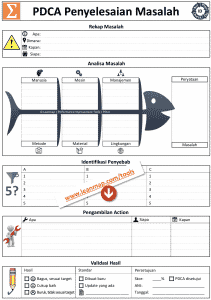

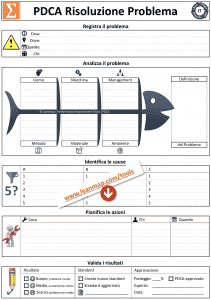

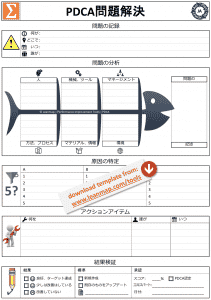

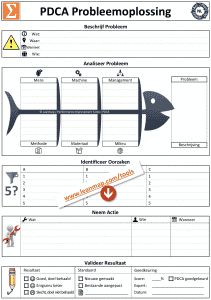

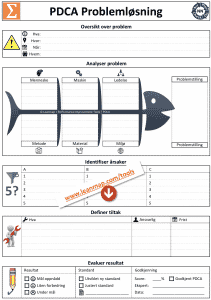

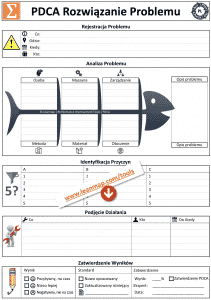

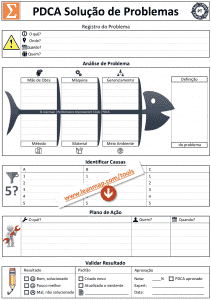

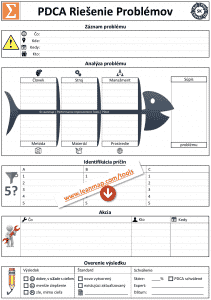

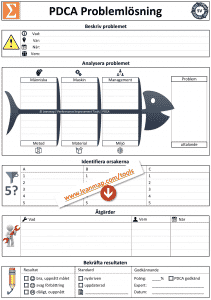

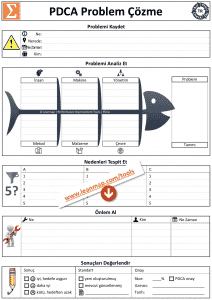

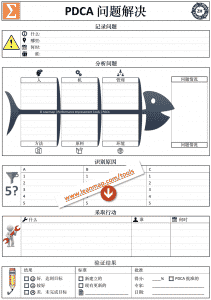

Several tools are available to aid in planning and monitoring project activities using the PDCA model. One of the most straightforward methods is to use this PDCA template .

Wrapping Up

PDCA represents the logical way of thinking we tend to follow when resolving problems and implementing continuous improvement. The objective is to make significant progress towards achieving the intended goal. Furthermore, it is important to note that the PDCA model stands at the core of almost all quality management systems. TQM, ISO standards and the A3 thinking process are all based around the PDCA philosophy.

Other Formats

Do you want to use the slides in your training courses?

PDCA Training Material – $18.85

Related Articles

Project Charter

Improvement Roadmap

Related Templates

A3 Problem Solving

Kaizen Event Charter

Written by:

CIToolkit Content Team

How to apply the Plan-Do-Check-Act (PDCA) model to improve your business

Reading time: about 7 min

- Professional development

- Project management

Most businesses want to improve. But when it comes to actually making needed changes, many fall short. Bureaucracy, silos, and even culture can block progress and stall innovation.

The Plan-Do-Check-Act model helps break companies out of stagnancy and transition to a system of continuous improvement. Learn how the PDCA cycle works and what benefits you can gain from using it at your company.

What is PDCA?

The Plan-Do-Check-Act (PDCA) model, also known as the Deming wheel or the Deming cycle, is an iterative method for continual improvement of processes, products, or services and is a key element of lean management.

The PDCA model was developed in the 1950s by William Deming as a learning or improvement process based on the scientific method of problem-solving. Deming himself called it by another term—the Shewhart cycle—because he created the model based on an idea from his mentor, Walter Shewhart.

As all of these names suggest, the PDCA cycle is a loop rather than an end-to-end process. The goal is to improve on each improvement in an ongoing process of learning and growth.

When should you use the PDCA process?

The Plan-Do-Check-Act model is a helpful tool that can be used for a number of applications:

- Exploring and testing multiple solutions in a small, controlled trial

- Avoiding waste by catching and adapting ineffective solutions before rolling them out on a large scale

- Implementing Total Quality Management or Six Sigma initiatives

- Developing or improving a process

What is great about the PDCA cycle is that it can be applied across industries and organizational types.

Pros and cons of PDCA

The PDCA cycle has a number of advantages and disadvantages. Consider both before you decide to apply Plan-Do-Check-Act to different projects.

Versatile: You can use PDCA in a variety of business environments and for a number of applications. Potential use cases include project management, change management, product development, and resource management.

Simple and powerful: The PDCA model is simple and easy to understand, yet it is a powerful driver for meaningful change and improvement while minimizing waste and increasing efficiency.

Hard to do: Though the model is simple, the work isn’t easy. Because PDCA breaks process improvements into smaller steps, it can be slow and probably isn’t a great solution for urgent projects.

Requires commitment: PDCA is not a one-time event. It is an ongoing, continuous process and therefore requires commitment and buy-in from the top down. Without committed leadership, the PDCA cycle can��’t work effectively for the long term.

The PDCA model

Sold? Learn the four stages in the PDCA cycle (which you can probably guess from the name) to start using it.

The planning stage is for mapping out what you are going to do to try to solve a problem or otherwise change a process. During this step, you will identify and analyze the problem or opportunity for change, develop hypotheses for what the underlying issues or causes are, and decide on one hypothesis to test first.

As you plan, consider the following questions:

- What is the core problem we need to solve?

- Is this the right problem to work on?

- What information do we need to fully understand the problem and its root cause?

- Is it feasible to solve it?

- What resources do we need?

- What resources do we have?

- What are some viable solutions?

- What are the measures of success?

- How will the results from a small trial translate to a full-scale implementation?

During this stage, an affinity diagram can help you and your colleagues organize a large number of ideas into groups. Once you have determined your course of action, write down your expected results. You will check your results against your hypothesis and expectations in the “Check” stage.

The next step is to test your hypothesis (i.e., your proposed solution). The PDCA cycle focuses on smaller, incremental changes that help improve processes with minimal disruption.

Test your hypothesis with a small-scale project, preferably in a controlled environment, so you can evaluate the results without interrupting the rest of your operation. You might want to test the solution on one team or within a certain demographic.

Once you have completed your trial, it’s time to review and analyze the results. This stage is important because it allows you to evaluate your solution and revise your plans as necessary. Did the plan actually work? If so, were there any hiccups in the process? What steps could be improved or need to be eliminated from future iterations?

Your evaluation at this stage will guide your decisions in the next step, so it is important to consider your results carefully.

Finally, it is time to act. If all went according to plan, you can now implement your tried-and-tested plan. This new process now becomes your baseline for future PDCA iterations.

Consider the following questions before you act:

- What resources do you need to implement the solution at full scale?

- What training is needed for successful implementation and adoption?

- How can you measure and track the performance of the solution?

- What opportunities are there for improvement?

- What have we learned that can be applied to other projects?

If the plan did not pan out as expected, you can cycle back to the planning stage to make adjustments and prepare for a new trial.

Plan-Do-Check-Act example

So what does the PDCA model look like in action?

In 2019, the Department of Obstetrics and Gynecology at the Ningbo Women and Children’s Hospital in China applied the Plan-Do-Check-Act model to shorten the emergency decision to delivery interval (DDI) time. This is the time it takes between the decision to conduct a caesarean section and the delivery of a newborn. Shortening this time period in emergency situations is critical to saving lives and improving patient outcomes.

Here’s how they did it:

Plan: In 2019, the hospital had an average DDI time of 14.40 minutes. Their process analysis identified three main causes impacting DDI time:

- A defective process

- Lack of first-aid experience

- Poor cooperation among departments

Do: The team developed improvement measures for each cause including:

- Simplifying the surgical process to speed up the pre-op routine

- Establishing a special DDI team to respond to emergency situations

- Standardizing DDI team working processes

- Creating an emergency treatment team, featuring senior doctors with clinical first-aid experience

- Implementing a variety of regular training, such as obstetrical safety meetings, emergency C-section process classes, and practical and theoretical trainings

- Conducting multi-department emergency treatment drills

Check: The hospital monitored and analyzed progress monthly, creating regular evaluation summaries and refining the cause analysis and improvement measures over time.

Act: After refining their processes, the hospital’s improvements optimized C-section delivery processes, increased collaboration across departments, and shortened the average emergency DDI to 12.18 minutes in 2020.

Supporting Kaizen with the PDCA cycle

The Plan-Do-Check-Act model is a particularly useful tool for companies who follow the Kaizen method . Kaizen is an organizational mindset and culture focused on small, frequent changes that lead to significant improvements over time.

The PDCA cycle supports the Kaizen philosophy by providing the framework for developing and implementing continuous improvements.

Using Lucidchart to continuously improve

Lucidchart is a visual workspace that helps teams and companies map out their processes and visualize their data in new ways. Use Lucidchart to visualize your PDCA cycle and help you through each step of the process. As you plan your project, you can create a fishbone (cause-and-effect) diagram to visualize problems and potential causes.

During the “Do” stage, map out the new processes you plan to try. Use data linking to connect real-time data to your diagrams and keep track of your results. Once you have a solution you’re ready to implement, use Lucidchart to create diagrams visualizing the new processes. Lucidchart makes it easy to share documents with your team so they can quickly learn and understand the changes.

If you’re continuously improving, it can be easy to lose track of your changes over time. Keep everyone on the same page by documenting your continual progress in Lucidchart.

Learn more about how to elevate your business.

Lucidchart, a cloud-based intelligent diagramming application, is a core component of Lucid Software's Visual Collaboration Suite. This intuitive, cloud-based solution empowers teams to collaborate in real-time to build flowcharts, mockups, UML diagrams, customer journey maps, and more. Lucidchart propels teams forward to build the future faster. Lucid is proud to serve top businesses around the world, including customers such as Google, GE, and NBC Universal, and 99% of the Fortune 500. Lucid partners with industry leaders, including Google, Atlassian, and Microsoft. Since its founding, Lucid has received numerous awards for its products, business, and workplace culture. For more information, visit lucidchart.com.

Related articles

The Kaizen methodology is an easy way to engage employees and develop a culture of continuous improvement. It strives to eliminate silos, egos, and waste and instead aims for efficient and standardized processes. See why you should use Kaizen and how you can get started.

No matter how good the idea, changes won't last without a solid process improvement plan in place. Learn the essential steps involved with every process improvement plan.

Bring your bright ideas to life.

or continue with

Plan, Do, Check, Act (PDCA)

PDCA is an improvement cycle based on the scientific method of proposing a change in a process, implementing the change, measuring the results, and taking appropriate action. It also is known as the Deming Cycle or Deming Wheel after W. Edwards Deming, who introduced the concept in Japan in the 1950s. It is also known as PDSA, where the “S” stands for “study”.

The PDCA cycle has four stages:

- Plan — determine goals for a process and needed changes to achieve them.

- Do — implement the changes.

- Check — evaluate the results in terms of performance

- Act — standardize and stabilize the change or begin the cycle again, depending on the results

PDCA is the foundation of continuous improvement or kaizen. Leaders set targets (plan) against a stable baseline of performance. Teams implement improvements (Do) to achieve the targets. Then they measure (Check) the change to evaluate performance against the target. If the team has achieved a measurable gain, it standardizes (Act) the new method by updating the standardized work. This ensures the improvement is stable.

History of PDCA

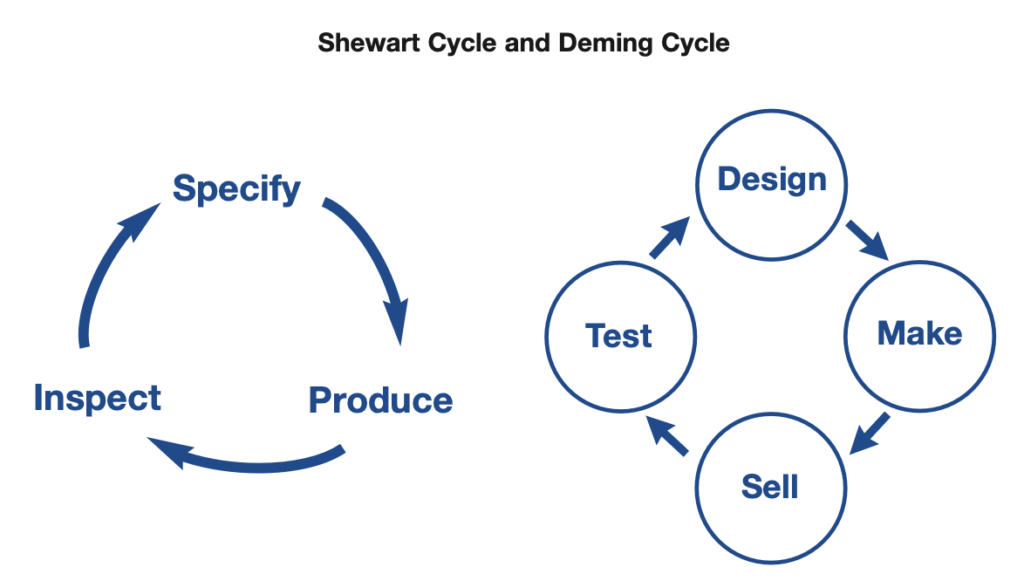

Walter A. Shewhart was the first to develop a repeating cycle for improvement dubbed the Shewhart Cycle:

Edward Deming expanded the Shewart cycle into a four-step pattern for Japanese audiences. The Deming cycle related heavily to the concept of product quality, innovation, and learning-by-doing over the entire life cycle of a product.

Specifically, the Deming cycle runs:

1. Design the product with appropriate testing. 2. Make the product and test it in production and in the lab. 3. Sell the product to the market. 4. Test the customer experience and redesign for improvement.

In 1951, the Japanese Union of Scientists and Engineers (JUSE) altered Deming’s framework into the more recognizable PDCA cycle. Although well over half a century has passed since the introduction of the Deming cycle to executives in Japan, most open-ended approaches still seek to repeat learning cycles as rapidly as possible, for obtaining customer feedback and making improvements in all pertinent areas.

The language may change slightly, but the basic thinking has not changed much. Consider the three-phase concept— Build , Measure , Learn —popularized by Eric Ries in his book, The Lean Startup . His iterative process is fundamentally similar to both the original Shewhart and Deming cycles. Words may change or be slightly altered, but the timeless, classic concepts stay the same.

Additional Resources

- Test Your PDCA Thinking By Reading Your A3 Backwards

- Create a Real A3, Do More Than Fill In Boxes

- Hazards at the Huddle Board: How to Coach a Team Away from “Fast Thinking” to Disciplined PDCA

- Practical Guidance for Using Humble Inquiry in PDCA Problem Solving and Coaching

- The Key to Lean — Plan, Do, Check, Act!

- Four Types of Problems — Art Smalley

Privacy Overview

by TickTick

PDCA Cycle Explained: 4 Steps for Continuous Learning and Improvement

The Meaning of PDCA Cycle

PDCA Cycle (also known as PDSA Cycle or Deming Cycle), is a problem-solving method used for the continuous learning and improvement of a process or product.

There are 4 basic steps in PDCA Cycle:

- Plan : identify a problem and possible solutions

- Do : execute the plan and test the solution(s)

- Check : evaluate the results and lessons learned

- Act : improve the plan/process for better solutions

These four steps incorporate inductive-deductive interplay and have been a simple and scientific approach for problem-solving (process-improving). It follows the curve of how we acquire knowledge through constant reflection, standardization, and modification.

The PDCA framework begins with a planning phase where a problem or a process to be improved is identified. This involves not only the goal setting and finding possible solutions, but also hypothesizing methods that can be used to reach the ultimate goal. Another thing that needs special attention is defining the success metrics. This simply means a clear evaluation matrix is ideally to be set beforehand.

Then, the solution(s) will be tested in the Do process. To detach the Do, there could be two steps: making the Do multiple To-Dos by splitting the task and defining them with a specific time, personnel, and steps, and collecting real-time data and feedback.

Check includes analyzing the results and comparing them to the hypothesis in the Plan stage: how well the solution worked, how much the goal has been achieved, and whether the methods were proven feasible. If there are any unexpected issues, you may also need to find the causes and possible solutions. Note that there might be forth and back between Do and check.

The Act step closes the cycle, which involves adjustment on the initial goal or solutions and integration of all key learnings by the entire process, to standardize successful parts and avoid error recurrence. In a nutshell, the Act phase summarizes the current cycle and prepares for the next.

However, the PDCA cycle doesn’t stop here. Instead, it can repeat from the beginning with a modified version of the Plan. There is no end to it and sustainability should be its main pitch.

How PDCA Has Evolved

Usually used interchangeably with “PDSA Cycle”, “Deming Cycle”, “Deming wheel”, “Shewhart Cycle” etc, the PDCA model has indeed confronted some misunderstanding and confusion. It remains unexplained in most cases how PDCA became what it is today and what’s the difference between those mysterious terminologies and how they interact. According to Ronald D. Moen & Clifford L. Norman , its evolution could be summarized like the following:

Shewhart cycle (1939): Specification - Production - Inspection .

He brought up this method from the viewpoint of Quality Control.

Deming Wheel (1950): Design the product - Make the product - Sell it - Test it .

Deming built off the Shewhart cycle and emphasized the four steps should be rotated constantly to aim for the product quality. This has gained increasing popularity when Deming participated in the Japanese Union of Scientists and Engineers (JUSE).

PDCA Cycle (the 1950s): Plan - Do - Check - Act.

A Japanese executive reworked the Deming Wheel and translated it into the PDCA Cycle for problem-solving. PDCA emphasizes more on the establishment of standards during the process and the ongoing modification of those standards.

Extended PDCA Cycle (1985): Plan - Do - Check - Act .

Kaoru Ishikawa refined the PDCA model to include more steps in the Plan and Do steps: Identify the goals and methods to use; involve in training and education during implementation.

PDSA Cycle (1985): Plan - Do - Study - Act .

Deming claimed that the ownership of PDCA Cycle was never recognized by anyone and the word “check” was used incorrectly because it means “to hold back”. Therefore, he replaced it with “study” to emphasize the importance of the continuous learning-improvement model.

How to Implement - PDCA Examples

Now, you’ve got a clear idea of what the PDCA Cycle is and how it changes over time. As a simple and structured method widely adopted in Quality Control and Total Quality Management, can it also be applied in wider areas, such as personal growth and business development? Yes, I’ll give you a couple of examples.

Benefits of PDCA Cycle

Among all those other methods, why does the PDCA model shade some lights in the history, especially known for the “Japanese Quality” and is still widely used today? Some key benefits of it need to be valued.

PDCA methodology emphasizes minimizing errors and maximizing outcomes. When applied to business development, e.g. a product’s iterations, it could ensure a developing path where the product is shaped better and better to the market and customers. It’s the same when it comes to personal growth. It also leaves space for constant check and reflection, which can avoid wasting time on the mistakes or making the same mistakes.

PDCA framework follows a learning curve and enhances the learning-improvement process continually. This is the key factor defining PDCA as a scientific and methodical way to gain knowledge. With knowledge building up, people’s ability goes up.

PDCA model encourages a growth mindset. Seeing continuous improvements is a good way to enhance individuals’ self-esteem levels and bring a great sense of accomplishment. People tend to find meaning in the things they do. Imagine if one stops making progress, they would stay in the static and lose meaning in repetitive work and life.

- PDCA Cycle is a simple and scientific way for problem-solving and process improvement.

- PDCA Cycle involves four key steps: Plan, Do, Check and Act.

- PDCA works slightly differently from Deming Cycle, Shewhart Cycle, and PDSA.

- PDCA Cycle is a never-ending process that can be used on a continual basis.

- PDCA Cycle can be used for quality control, business development, and personal growth.

Related Posts:

Time Blocking: How It Helps You Take Control of Your Time

How to Achieve a Happier Life with Mindfulness

8 Useful Tips for Making New Year’s Resolutions

- What is the (PDCA) Plan, Do, Check, Act Cycle?

- Learn Lean Sigma

- Improvement Methodology

PDCA (Plan, Do, Check, Act) is a time-tested methodology that forms the backbone of continuous improvement in various industries. The PDCA cycle, which embraces simplicity and systematic progression, facilitates problem-solving and process improvement by following four distinct stages. These stages create a circular flow that promotes continuous refinement and adaptation.

The PDCA cycle provides a structured approach that can be tailored to various scenarios, whether you’re looking to address specific organizational challenges, standardize processes, or foster innovation. This article delves into the essence of PDCA, examining its four phases, applications, and why it is such an effective tool for continuous growth and improvement. Join us as we unpack the PDCA cycle’s dynamics, providing insights and practical advice on how to effectively apply this time-tested methodology in your organization or project.

Table of Contents

What is pdca.

PDCA (Plan, Do, Check, Act) is a four-step methodology for continuous improvement and problem solving in a variety of organizational processes. It starts with planning (Plan) a change or solution, then doing (Do) it on a small scale. The results are then evaluated (Check) to determine the effectiveness of the plan, leading to the final action (Act) of either broadly implementing the change or revising the plan. The cyclical nature of PDCA encourages continuous refinement and adaptation, making it a versatile tool for improving quality, efficiency, and innovation in a wide range of industries and settings.

Why use PDCA?

The PDCA (Plan, Do, Check, Act) cycle is an indispensable tool in the world of process improvement and project management, and here’s why it’s so widely embraced:

1. Simplicity and Structure:

PDCA offers a simple and structured approach that anyone can follow. Its four-stage cycle – Plan, Do, Check, Act – provides clear guidelines that can be applied to various problems and processes. This simplicity makes it accessible to team members at all levels, fostering inclusivity and alignment.

2. Adaptability:

The cycle is not confined to a specific industry or project type. It’s a flexible framework that can be adapted to different contexts, whether it’s manufacturing, logistics, or healthcare. This adaptability makes it a universal tool for continuous improvement.

3. Continuous Improvement:

Unlike linear models, PDCA operates in a continuous loop. After the Act stage, the cycle repeats, allowing for ongoing refinement and optimization. This iterative nature ensures that improvements are sustained and built upon, leading to long-term growth and excellence.

4. Risk Mitigation:

By encouraging small-scale testing and careful analysis (Do and Check stages), PDCA helps in identifying and mitigating risks early in the process. This controlled approach minimizes the chances of large-scale failures and promotes a culture of thoughtful experimentation.

5. Enhanced Communication and Collaboration:

The clear structure of the PDCA cycle facilitates communication and collaboration within teams. Everyone knows the stage of the process and their role in it, leading to greater synergy and efficiency.

6. Problem-Solving and Innovation:

PDCA’s systematic approach encourages problem-solving and innovation. By continuously evaluating and adapting the plan, organizations can discover new solutions and approaches that may not have been apparent at the outset.

What are the four phases of the PDCA cycle?

The PDCA cycle has four key stages as can be seen in the graphic below.

Stage 1 – Plan – identify and define the problem, creating a plan for the change.

Stage 2 – Do – Test the potential solutions from the plan.

Stage 3 – Check – Study the results, analyze the results and understand what you have learnt.

Stage 4 – Act – Take action based on the outcome of the previous step. If the change worked implement what was learnt from the test into the full process. If the change does not produce the required results repeat the cycle with a different plan.

Within the planning stage, it is important to have a clear understanding of what the problem is you are trying to solve. Ensure those involved all have a clear and consistent understanding.

Once a consistent understanding has been established, you need to create a plan.

Within your plan is important to consider:

- What are the goals?

- How are we going to do it?

- What resources do we need?

- Who is responsible for taking action?

- When are the actions going to be done?

Start implementing the plan as set out in the previous stage. Ensure everyone knows their role and responsibility, consider creating an effective communication plan for all stakeholders as changes to the process are likely and you need to ensure those involved understand what is happening and why.

You might find that the plan needs to adjust during this step as you implement your plan, therefore it is advised to start small and then expand once you are confident in the plan.

Review the results of the trial from the previous stage, did this produce the expected results?

Ensure you review the results with the team involved as they will be able to provide insight and understanding of the results based on their involvement.

Ensure you have collected sufficient data so that the test is statistically significant and not just a one-time result with may not be repeated.

Once everything has been tested and reviewed if the results meet the expected outcome it is time to implement the solution full-time into the process. Ensure all stakeholders are fully aware of what the change is and what they need to do to sustain the change. Tools such as Standard Operating Procedures (SOPs) or other training aid are useful in this step. During this stage it is useful to continue to check the process for a period of time after to ensure all issues have been resolved and that the problem does not reappear elsewhere.

Once this improvement is closed out you can repeat the cycle with further improvements to continually make improvements to the process.

If the results from the test do not meet the expected outcome return to the plan stage and repeat the process with a different potential solution.

When to use the PDCA cycle?

When an organization is looking to improve its processes or when a specific problem needs to be addressed, the PDCA cycle is frequently used. In this answer, we will go over when and how to use the PDCA cycle for project improvement.

- When there is an issue or problem: The PDCA cycle is frequently used to solve problems or issues that an organisation may be experiencing. When a problem arises, the PDCA cycle can be used to identify the root cause of the problem, develop a solution, implement the solution, and then evaluate the results to determine if the problem has been solved. This can assist organisations in addressing issues quickly and effectively while minimising their impact on the business.

- When continuous improvement is required: When an organisation wants to continuously improve its processes or products, the PDCA cycle is used. Organizations can use the PDCA cycle to identify areas for improvement, develop and implement a plan to address those areas, and then evaluate the results to see if the changes have resulted in an improvement. This can assist organisations in remaining competitive and meeting their customers’ changing needs.

- When standardisation is required : The PDCA cycle can also be used to standardise processes within an organisation. Organizations can use the PDCA cycle to identify best practices, develop standard processes, implement those processes, and then evaluate the results to ensure that the processes are functioning as intended. This can assist organisations in increasing efficiency, reducing waste, and ensuring consistent quality.

- When innovation is required: The PDCA cycle can also be used to drive innovation within an organisation. Organizations can use the PDCA cycle to generate new ideas, test those ideas, evaluate the results, and then implement the best ideas. This can assist organisations in staying ahead of the competition and discovering new ways to meet their customers’ needs.

The PDCA methodology is usually best suited to situations where the improvement needs a small amount of resouces and is a less intense problem. Whereas if these are greater you may consider A3 , 8D , DMAIC or DFSS for your project.

In conclusion, the PDCA cycle is a useful methodology for improving processes, products, and services within an organisation. It can be used in a variety of situations, including when there is a problem or issue, when continuous improvement is required, when standardisation is required, and when innovation is required. Organizations can use the PDCA cycle to quickly identify areas for improvement, develop and implement plans to address those areas, and then evaluate the results to ensure that the desired outcomes are met.

To summarise, the PDCA cycle is a valuable methodology for organisational continuous improvement. It is a straightforward approach that can be applied to small or simple change projects and is also known as the Deming cycle or Shewhart cycle. The PDCA cycle’s four stages: Plan, Do, Check, and Act, provide a logical sequence of steps for problem-solving. It enables controlled trials of potential solutions with adequate analysis prior to full implementation.

PDCA is useful for keeping the project team on track, facilitating communication, and keeping stakeholders focused. It is ideal for simple improvement projects that do not require extensive analysis. It is a powerful tool for organisations seeking to improve their efficiency and achieve continuous improvement.

- Moen, R. and Norman, C., 2006. Evolution of the PDCA cycle .

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

The Evolution of 8D Problem-Solving: From Basics to Excellence

In a world where efficiency and effectiveness are more than just buzzwords, the need for…

8D: Tools and Techniques

Are you grappling with recurring problems in your organization and searching for a structured way…

How to Select the Right Lean Six Sigma Projects: A Comprehensive Guide

Going on a Lean Six Sigma journey is an invigorating experience filled with opportunities for…

- Your Project

What is the PDCA Model?

The PDCA Model is a Problem-Solving tool that suggests 4 simple Steps to achieve Goals efficiently .

- Its Name is an acronym for the Steps suggested: P lan, D o, C heck, A ct.

These steps can (or should) be repeated cyclically in order to improve the results obtained.

As in many other Continuous-Improvement tools, the more you repeat the cycle, the closer you will be to finding the solution or reaching the end goal .

Four Steps of the PDCA Model

1. Plan : In this first Step, you should:

- Define the Problem or the Goal you want to achieve.

- Design a Strategy or a Method to do it.

2. Do : In this Step, you should:

- Implement the necessary actions to comply with the Plan.

3: Check : In this Step, you should:

- Check the results obtained.

- Choose and Use the right metrics .

- Find out what worked and what didn’t .

4: Act : In this Step, you should:

- Adopt the modifications that have proven to work.

- Come up with a new Plan to fix what isn’t working yet.

This cycle is meant to be repeated frequently :

- If you have not been able to reach your initial Goal, you must repeat it until you have achieved it.

- If you have reached your initial Goal, you should look for the Next one .

Let’s see the first example so that you understand it better:

PDCA Model example

Imagine that you own a Restaurant specialized in ribs .

- You think people are a little “tired” of your recipe.

You want to discover a new recipe that will drive your customers crazy.

Since you are not a very methodical person, you decide to use the PDCA Model:

Your Goal is to find a new successful Recipe for your Ribs .

- You’ll start offering 5 alternatives to your Clients.

- Every week, you will keep the top 3 and introduce 2 new ones .

You’ll use an iterative process to find which ingredients and cooking processes your customers like best .

The first week, you prepare the 5 best recipes you know , listing all the ingredients that each one has and what cooking processes you followed.

- Once you have feedback, you’ll make different modifications.

At the end of every week, you check the most successful recipes.

- The ingredients they have (spices, amount of salt, rib supplier, etc).

- The cooking process used (which charcoal yo used, how much time you employed, etc).

Your goal in this step is to see if your recipes are going in the right direction .

Once you have checked the best recipes, you analyze and decide what new recipes you will use next week .

- After 3 months of research, you end up with a successful recipe that has been undefeated for 4 consecutive weeks .

As you may be thinking right now, this model can be used in very different situations in very different ways.

But why is it important that you use it?

Why is the PDCA Model important?

In general, people tend to be chaotic when looking for solutions to their problems.

- Once we’ve found a “solution” we don’t look for a better option .

The PDCA Method offers you 4 simple Steps to follow and encourages you to keep improving your results permanently .

As we always say: Just because something is intuitive doesn’t mean it’s obvious .

But, when should you use this Tool?

When should you use the PDCA Model?

This is one of the few methods that can be used in any situation .

Even if you don’t use it explicitly, you can act according to its dynamics :

- To Plan something, Do it, Check your results and Modify what needs to be modified.

If is a very simple and flexible Model that can be very useful:

- For Starting new Projects.

- To improve a Product or Service.

- To improve Personal Skills.

You can even use it to lose a few kilos.

PDCA Model examples

Now, we will share with you some examples of different situations where the PDCA Model can be of great help .

Let’s begin:

Clothing Store - PDCA Model example

Now, let’s imagine you have started your own Clothing Store .

- However, you’re still not sure which product line would best suit your customers’ preferences.

You decide to use the PDCA Model:

Every 2 weeks, you’ll introduce 2 new product lines .

At the end of those 2 weeks, you’ll analyze:

- Which products brought more customers.

- Which products gave you the most benefits.

Depending on the results obtained, you’ll decide which new product-lines you’ll introduce the next 2 weeks .

- You’ll repeat this process for the next 6 months.

Every 2 weeks, you introduce the new products.

You decide promote the new products as special opportunities .

- This way you won’t give a chaotic impression to your customers.

At the end of every 2 weeks you analyze your results:

- Number of clients you have received.

- Customer preferences.

- Benefits obtained.

Have the changes taken effect?

Finally, you decide what new product lines you will introduce the next 2 weeks .

- Since you would need some time to talk to your suppliers, you could introduce a 1 month delay in your operations.

The products that work best will give you an idea of what to do.

- After 6 months, you find the product line that bests suits your customers’ preferences and maximizes your profits .

Blogging - PDCA Model example

Now, we’re going to imagine that you have just started your own Blog .

- This is a very common situation.

Therefore, you decide to use the PDCA Method:

Since Google needs time to Rank content correctly, you will develop a 1-year plan .

The first 6 months, you’ll write about 5 different Topics that you like the most .

- If you want to have a successful Blog, you need to love what you write about.

After those 6 months, you’ll decide what 3 Topics you’ll write about the next 6 months .

- By choosing the 3 most popular Topics.

Finally, after 1 year, you’ll chose your final main Blog Topic .

Every week, you’ll write 2 good Blog Posts .

- In the first 6 months, you’ll have written 10 Posts of each Topic.

After 6 months you analyze:

- Which Topics were most popular.

- What Post Structure was most successful (length, appearance).

Google offers an infinity of tools and metrics for this.

Were your assumptions and predictions correct?

After 6 months, you decide what Topics to focus on and what Structure you will follow the next 6 months.

- After an exhausting year, you finally have found your niche and your results do not stop growing .

Personal Trainer - PDCA Model example

Now, you are a Personal Trainer .

- You have different clients that you train regularly.

You are thinking of a new type of training but you are not sure how to design it.

You then decide to use the PDCA Method:

You decide to offer 4 of your Clients a new training method.

You will test different versions of it and measure the Weight loss and Customer satisfaction of each version .

After 2 months , you’ll decide what modifications you can make to each training method and you’ll repeat the whole process with 4 new Clients .

You’ll repeat this cycle 3 times: you’ll need 6 months .

Every week, you prepare the training of your 4 “special” Clients closely, measuring :

- Their satisfaction (with a simple and quick test).

- Their weight loss .

- Their health in general.

Every 2 months, you collect all the results obtained and decide what works best and what doesn’t .

- By doing this you can introduce further modifications for the training of the new 4 clients.

Finally, you introduce the modifications necessary for the new training programs and you offer it to 4 different Clients .

- After 6 months you end up with a new effective training that people love .

Summarizing

The PDCA Model is an iterative problem-solving tool that proposes 4 simple Steps to achieve Goals efficiently.

- These steps should be repeated cyclically until the Goal has been achieved.

The 4 Steps proposed are:

- Plan : Prepare your Goals and Strategy.

- Do : Take the necessary actions.

- Check : Test your results.

- Act : Introduce the necessary modifications.

- The PDCA Method offers 4 simple Steps to follow.

It is a very simple and flexible model that can be used in many situations.

- Economies of Scale

- Business Plan for Beginners

- Business Plan Basics

- How to write a Business Plan

- Cash Flow Calculation

- Raising Funds for a Business

- 4 C’s of Credit

- Business Plan Templates

- Customer Insight

- Customer Experience

- Customer Pain Points

- 4C Marketing Model

- RATER Model

- Augmented Product

- Product Mix

- Unique Selling Proposition

- DAGMAR Model

- Marketing Storytelling

- Content Marketing

- Psychographics

- Barnum Effect

- Market Segmentation

- Market Research & Big Data

- Marketing to Generation Z

- 4P Marketing Mix

- 7P Marketing Mix

- Sales Funnel

- Loyalty Ladder

- RACE Planning

- Push and Pull Marketing

- Marketing Strategy

- Marketing Templates

- Starting your own business

- From Startup to a Business

- Entrepreneur FAQs

- Start your Business Idea

- Entrepreneur Golden Rules

- Innovate or Imitate?

- Design Thinking

- SCAMPER Model

- AAR Process

- Work From Home

- Growth strategies for Startups

- VMOST Analysis

- 3P Framework

- SOAR Analysis

- TELOS Analysis

- 5 C’s of Entrepreneurship

- Crowdfunding

- BATNA & ZOPA Negotiation

- Entrepreneur with no Money

- Entrepreneurship Templates

- Strategy vs Tactics

- Mission and Vision

- Business Values

- Value Chain

- Scenario Planning

- Porter 6 Forces

- Bowman’s Strategy Clock

- GE-McKinsey Matrix

- Delta Model

- PEST Analysis

- PESTEL Analysis

- SWOT Analysis

- VRIO Framework

- Strategy Canvas

- Competitive Advantages

- Porter’s Four Corners

- 5 Ps of Strategy

- Porter’s Generic Strategies

- Porter’s Diamond Model

- Wardley Map

- Core Competencies

- Resource Based View

- Bridges Transition Model

- CAGE Distance Framework

- McKinsey’s 3 Horizons

- Vertical Integration

- Horizontal Integration

- Blue Ocean Strategy

- Red Ocean Strategy

- Porter 5 Forces

- Ansoff Matrix

- McKinsey 7S Framework

- CATWOE Analysis

- Strategy Pyramid

- Bain’s RAPID Framework

- Balanced Scorecard

- Resources and Capabilities

- Strategy of Apple

- Strategy of Amazon

- Strategy of Starbucks

- Strategy Templates

- Communicate Effectively

- COIN Conversation Model

- SCARF Model

- SBI Feedback Model

- CEDAR Feedback Model

- How to behave at a meeting

- Gibbs’ Reflective Cycle

- Bloom’s Taxonomy

- 5E Learning Model

- 9-Box Performance Grid

- SEEDS Bias Model

- Halo Effect

- Pygmalion Rosenthal Effect

- Dunning-Kruger Effect

- How to be an Entrepreneur

- How to be a Leader