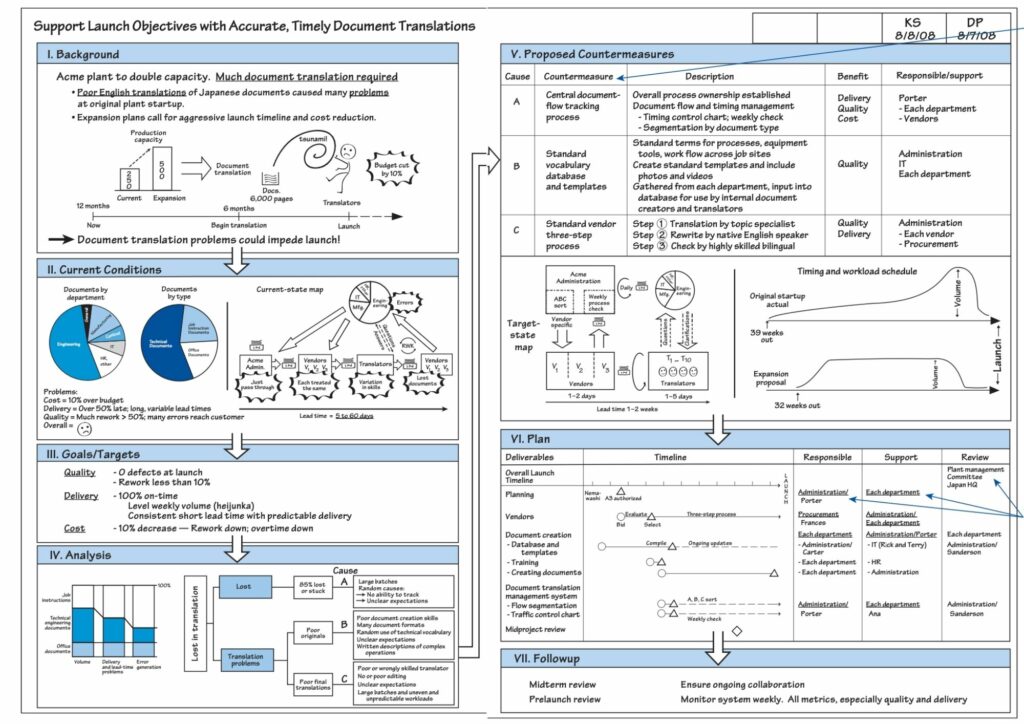

An A3 Report is a Toyota-pioneered practice of getting the problem, the analysis, the corrective actions, and the action plan down on a single sheet of large (A3) paper, often with the use of graphics. At Toyota, A3 reports have evolved into a standard method for summarizing problem-solving exercises, status reports, and planning exercises like value-stream mapping.

But it is much more than a sheet a paper with facts and figures. It is a management process learned through dialogue about concrete problems. It does this by means of a dialogue between a lean manager and a subordinate who learns lean management and leadership as she solves an important problem.

This process of solving problems while creating better employees—A3 analysis—is core to the Toyota management system. An A3 report guides the dialogue and analysis. It identifies the current situation, the nature of the issue, the range of possible counter- measures, the best countermeasure, the means (who will do what when) to put it into practice, and the evidence that the issue has actually been addressed.

The lean leader’s job is to develop people. If the worker hasn’t learned, the teacher hasn’t taught. Training Within Industry Report (Washington, DC: War Manpower Commission, Bureau of Training, 1945).

Effective use of the A3 process can facilitate the shift from a debate about who owns what (an authority-focused debate) to a dialogue around what is the right thing to do (a responsibility-focused conversation). This shift has a radical impact on the way decisions are made. Individuals earn the authority to take action through the manner in which they frame the issue. They form consensus and get decisions made by focusing relentlessly on indisputable facts that they and their peers derive from the gemba.

As a result, A3 management can best be understood as neither “top-down” nor “bottom-up.” The process clarifies responsibility by placing ownership squarely on the shoulders of the author-owner of the A3, the individual whose initials appear in the upper right-hand corner of the paper. This person may not have direct authority over every aspect of the proposal. Yet this owner is clearly identified as the person who has taken or accepted responsibility to get decisions made and implemented .

Example A3s

The Many Facets of A3

- A standard paper size: At its most fundamental, “A3” is the international term for a sheet of paper 297 millimeters wide and 420 millimeters long. The closest U.S. paper size is the 11-by-17-inch tabloid sheet.

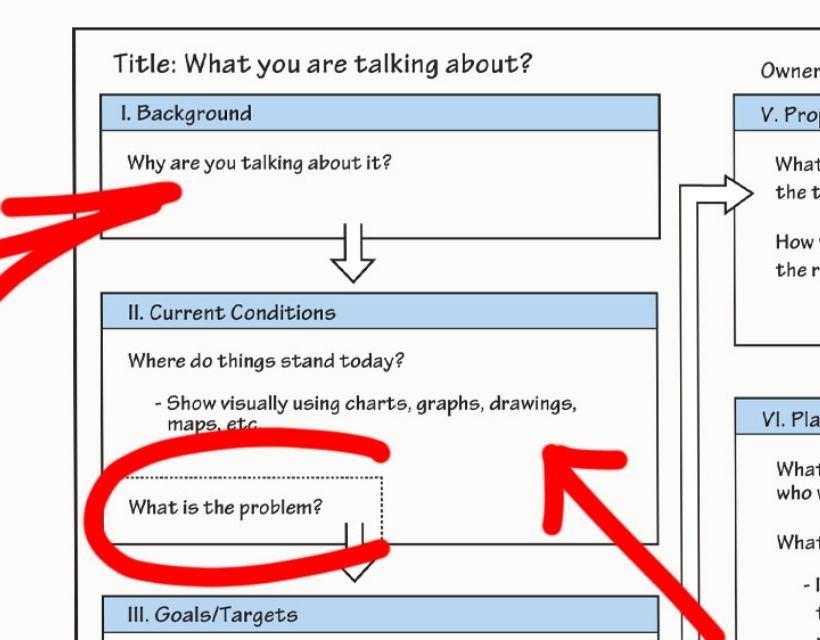

- A template: Many companies and individuals use an A3-sized document pre-printed with the steps needed to conduct lean problem-solving or improvement efforts, with generous white space for “A3 owners” to record their progress. While they refer to this document as a template, an “A3” is not a template.

- A storyboard: As users record their problem-solving or improvement project’s progress, the A3 becomes a storyboard used to facilitate communication, collaboration, and coordination with other stakeholders affected by the goal the A3 owner is working toward (e.g., solving a problem or improving a process ). By having all the facts about the effort in one place, logically presented and summarized, the A3 owner is better able to gain buy-in from other stakeholders for recommended process changes.

- A report: Once the A3 problem-solving effort concludes, the A3 storyboard serves as a report of the problem-solving or improvement initiative, including the facts and data gathered, hypotheses considered, countermeasures tried, experiment results, corrective actions taken, and the overall thinking of the A3 owner and stakeholders. At Toyota and elsewhere, A3 reports have evolved into a standard method for summarizing problem-solving exercises, status reports, and planning exercises like value-stream mapping.

- A problem-solving methodology (or process): Most lean practitioners know “the A3” as a problem-solving process guided by specific steps or questions. The left side of the A3 focuses on various elements of the problem or current condition, and the right on the countermeasures considered, tested, and chosen that resolves the issue or creates a higher standard.

- A management discipline (or process): At a higher level, lean leaders, managers, and supervisors use “the A3” as a means by which they oversee and guide subordinates while simultaneously helping them develop their lean thinking and practice — particularly lean leadership and problem-solving — capabilities. With A3 management, leaders challenge their direct reports to solve a problem. Then, with the A3 report guiding the dialogue and analysis, leaders coach them through the problem-solving process. Importantly, leaders coach by asking questions versus providing answers, ensuring responsibility remains with the subordinate to solve the problem by pursuing facts and building consensus. Through this interaction, subordinates address the issue, allowing them to make progress toward the objective and, in so doing, learn the lean approach to leadership and management and gain problem-solving capability.

- A3 thinking (or analysis): Most A3 coaches and advanced lean practitioners refer to “the A3” as a thinking process. In this case, the term refers to a systematic approach to resolving problems or improving work processes. Someone can follow this systematic approach, regardless of whether they are guided by or record their findings on an A3 document.

- An alignment tool: Advanced lean organizations that have incorporated lean thinking and practices throughout their operations use “A3s” as part of their strategy deployment and execution efforts. In this case, the A3 process ensures a standard approach to managing and coaching people, all directed toward solving problems that help achieve corporate objectives.

Additional Resources

How Do I Start My A3?

When asked “where do I start to write my A3,” David Verble responds “don’t start by writing.” His piece, the first in a series about getting started, offers lessons he has learned about the nature of thinking, and a productive way to start the A3 by recognzing it as a thinking process.

Don’t Present Your A3: Share Your A3

When asked “where do I start to write my A3,” David Verble responds “don’t start by writing.” His piece, the first in a series about getting started, offers lessons he has learned about the nature of thinking, and a productive way to start by recognizing it as a thinking process.

Related Books

Related Online Courses

Intro to Problem Solving

Problem-solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all of your senses to understand what is truly happening.

See: Value Stream Mapping

Privacy Overview

- Guide: A3 Problem Solving

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: June 13, 2023

- Learn Lean Sigma

Problem-solving is one of the key tools a successful business needs to structure improvements and one I have been using to solve problems in a structured way in my career at a range of businesses over the years. When there is a problem in business that is leading to increased costs, waste , quality issues, etc., it is necessary to address these problems. A3 structured problem solving is a Lean Six Sigma methodology that has been designed and developed to support continuous improvement and solve complex business problems in a logical and structured process.

The guide will give you a full understanding of what A3 Problem solving is and a breakdown of all the steps of how to apply it within your business with an example of where I have made improvements with it previously.

Table of Contents

Importance of a3 in lean management.

The A3 problem-solving method is a key tool in Lean Six Sigma and continuous improvement in business, and in my experience, it is often the standard approach all improvement activities must follow and is particularly popular in the automotive industry. This is because of the following:

Focus on Root Causes : Rather than applying a quick fix to a problem or jumping to conclusions and solutionizing, A3 requires gaining a deep understanding of the root causes of the problem. By addressing these root causes, the chances of recurrence is reduced.

Standardization : With a consistent format, the A3 process ensures that problems are approached in a standardized way, regardless of the team or department. This standardization creates a common language and understanding across the organization and ensures all problems are addressed to the same standard and approach.

Team Involvement : An A3 isn’t an individual process. It requires a cross-functional team to work together on problem-solving, ensuring that a range of perspectives and expertise is considered. This collective approach builds a stronger understanding of the problem and ensures that solutions are well-rounded and robust.

Visual Storytelling : The A3 report serves as a visual storyboard, making it easier for stakeholders at all levels to understand the problem, the analysis, and the countermeasures. This visualization enhances communication and drives alignment.

The 6 Steps of A3 Problem Solving (With Real Example)

The A3 problem-solving process can initially seem difficult if you have never done one before and particularly if you have never been a team member in one. To help you with this we will break down the 6 steps into manageable activities, followed by a real-life example to help you apply this method within your business.

As a side note, the A3 problem-solving process was actually one of the first Lean Six Sigma tools I learned to use three weeks into my continuous improvement career after being thrown into the deep end due to resource availability, so I can understand how difficult it can be to understand.

Step 1: Describe the problem

Problem description.

The problem description is an important first step in the process as it ensures a common understanding with the team of what the issue is that needs to be addressed. This can be done by using a technique called the 5W1H Is/Is Not method to help gain a clear understanding of the problem.

To understand the 5W1H Is/Is Not the Process, check out our guide for details of that technique. However, in short, it’s about asking key questions about the problem, for example, “What IS the problem?” and “What IS NOT the problem?”

Let’s say you have been asked to look into a problem where “Machine downtime on the automotive assembly line has increased by 30% over the past three months, leading to production delays and increased costs.”

An example of a 5W1H Is/Is Not on this may result in the following output:

Based on this we can create a clear problem description as the focus of the project that give the team a clear and common understanding of the issue looking to be resolved in the next steps of the process. The problem description could then be written as:

“Over the past three months, machine downtime on Automotive Assembly Line No.3 has increased by 30%. This has predominantly affected the assembly line workers and leads, leading to production delays and higher labour costs. “

Current Condition

Next is demonstrating the current condition and demonstrating the impact on the business. This can often be done with data and charts to back up the problem that might show trends or changes in outputs.

This might look something like the below and demonstrate a good baseline for confirming the improvement at the end of the A3

Containment Actions

Next is containment actions. Since you have identified a problem, there is likely an impact on the business or the customer. As a team, you should consider what can be done to limit or eliminate this problem in the short term. Remember this is just a containment action and should not be seen as a long-term fix.

In our situation we decided to “Implement temporary overtime shifts to meet production goals, leading to an increase in labor costs.”

At this stage, the A3 should look similar to the one below; you can use charts and graphics to represent the current state as well if they fit within the limit area. Remember, we must include the content of the A3 within the 1-page A3 Document.

Step 2: Set the A3 Goals

The next step of the A3 is to, as a team, set the goal for the project. As we have a clear understanding of the current condition of the problem, we can use that as our baseline for improvement and set a realistic target for improvement.

A suggested method for setting the Target condition would be to use the SMART Target method.

If you are not familiar with SMART Targets , read our guide; it will cover the topic in much more detail. In short, a SMART target creates a goal statement that is specific, measurable, achievable, relevant and time-bound.

By doing this you make it very clear what the goal of the project is, how it will be measured, it is something that can be achieved, relevant to the needs of the business and has a deadline for when results need to be seen.

For our A3 we decided that the goal would be “Our goal is to achieve at least a 20% reduction in machine downtime on Automotive Assembly Line No.3, lowering it from 90 minutes to no more than 72 minutes per day per machine, within the next 60 days. This reduction is crucial for increasing productivity and reducing labour costs, aligning with our overall business objectives.”

I also recommend using charts in this section to visualize the benefit or improvement to ensure you have stakeholder and sponsor support. Visuals are much easier and faster for people to understand.

At this point, your A3 might look something like the one below, with the first 1/4 or section complete. The next step is to move on to the root cause analysis to get to the root of the problem and ensure the improvement does not focus on addressing the symptoms of the problem.

Step 3: Root Cause Analysis

Root cause analysis is the next step in the process, often referred to as gap analysis, as this step focuses on how to get to the goal condition from the current condition.

Tip: If at this point you find the team going off-topic and focusing on other issues, Ask the question, “Is this preventing us from hitting our goal statement?” I have found this very useful for keeping on track in my time as an A3 facilitator.

For root cause analysis, a couple of key tools are usually used: a fishbone diagram and a five-why Analysis . Again, we won’t go into the full details of these tools within this guide, as they have been covered in extensive detail in their own guides.

But the aim at this point is as a team, to brainstorm what is preventing us from achieving our target condition. This is done by allowing all members of the team to input the reasons they think it is not being achieved. These inputs are often written on sticky notes and placed on the fishbone diagram. Following this, you may have results similar to the ones below. Note: it is important that the inputs are specific so they can be understood. e.g. “Calibration” alone is not specific to how it’s causing the problem; specify it with “Calibration: Inaccurate measurements affecting machine settings.”

After the fishbone diagram has been populated and the team has exhausted all ideas, the team should then vote on the most likely cause to explore with a 5 Whys analysis. This is done because, due to resource limitations, it is unlikely all of the suggestions can be explored and actioned.

In this situation the team decided the “lack of preventative machines: machines not being serviced regularly” was the cause of increased downtime. This was explored with the 5 Whys to get to the root cause of why Assembly Line 3 did not have preventative maintenance implemented.

The result of this root cause analysis can be seen below, and you may end up with more ideas on the fishbone, as generally there are a lot of ideas generated by a diverse team during brainstorming.

Step 4: Solutions and Corrective Actions

Now that we understand what the root cause of the problem is, we need to address it with solutions and corrective actions. Again, as a team, consider the root cause of the problem and discuss what actions need to be taken by the team, who will do them, and when they will be done. The result should be an action plan, for example, like the one below:

This action plan needs to be carried out and implemented.

The result of this section will likely just be an action list and look like the below section.

Step 5: Validate Solution and Standardize

Within step 5 it is time to collect data to validate and confirm the actions that have been implemented resulting in solving the problem and meeting the target state of the problem. This is done by continuing to collect data that demonstrates the problem in the baseline to see if the problem is being reduced.

For example, below, the project team continued to collect Assembly Line 3 downtime data on a weekly basis. Initially, there was a steady reduction, likely due to the focus of the project on the problem, which had some impact. However, once the majority of the action was implemented, a huge drop in product downtime was seen, exceeding the target. This showed the actions have been successful

If, in the validation stage, you find that the improvement required is not being made, you should go back to step 3 and reconsider the root cause analysis with the team, pick another area to focus on, and create an action plan for that following the same steps.

Step 6: Preventive Actions and Lessons Learned

In step 6 after the confirmation of project success you should look at preventive actions and lessons learned to be shared from this project:

- Preventive Action: The new preventive maintenance schedule will be standardized across all assembly lines. This will prevent other lines having similar issues and make further improvements

- Lessons Learned: A formal review will be conducted to document the process, including challenges faced and how they were overcome, which will then be archived for future reference.

In our project, this looked like the one below and will be used as a reference point in the future for similar issues.

And that is the successful completion of a structured A3 problem-solving technique.

The complete A3 looks like the below image. Yours may slightly differ as the problem and information vary between projects.

Downloadable A3 Reporting Template

To support you with your A3 problem solving, you can download our free A3 problem solving report from the template section of the website.

Problem-solving is important in businesses, specifically when faced with increased costs or quality issues. A3 Structured Problem Solving, rooted in Lean Six Sigma, addresses complex business challenges systematically.

Originally from Toyota’s lean methodology, A3, named after the 11″x17″ paper size, visually maps problem-solving processes. This method ensures concise communication and focuses on crucial details, as illustrated by the provided example.

Emphasized in Lean Management, A3 stresses understanding root causes, standardization across teams, team collaboration, and visual representation for clarity. This tool is not only a guide to understanding the issue but is a standardized format ensuring robust solutions. Particularly for novices, breaking down its six steps, from problem description to setting A3 goals and root cause analysis, provides clarity. Visual aids further enhance comprehension and alignment across stakeholders.

- Sobek II, D.K. and Jimmerson, C., 2004. A3 reports: tool for process improvement. In IIE Annual Conference. Proceedings (p. 1). Institute of Industrial and Systems Engineers (IISE).

- Matthews, D.D., 2018. The A3 workbook: unlock your problem-solving mind . CRC Press.

Q: What is A3 problem solving?

A: A3 problem solving is a structured approach used to tackle complex problems and find effective solutions. It gets its name from the A3-sized paper that is typically used to document the problem-solving process.

Q: What are the key benefits of using A3 problem solving?

A: A3 problem solving provides several benefits, including improved communication, enhanced teamwork, better problem understanding, increased problem-solving effectiveness, and the development of a culture of continuous improvement.

Q: How does A3 problem solving differ from other problem-solving methods?

A: A3 problem solving emphasizes a systematic and structured approach, focusing on problem understanding, root cause analysis, and the development and implementation of countermeasures. It promotes a holistic view of the problem and encourages collaboration and learning throughout the process.

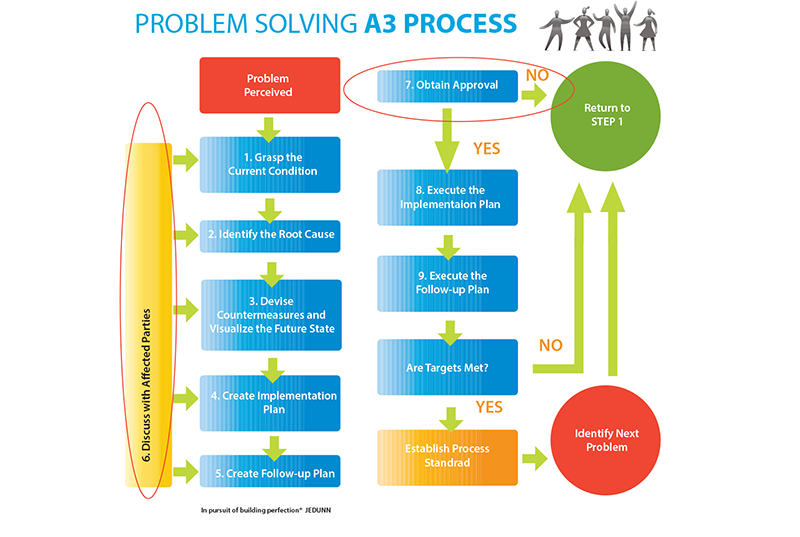

Q: What are the main steps in the A3 problem-solving process?

A: The A3 problem-solving process typically involves the following steps: problem identification and description, current condition analysis, goal setting, root cause analysis, countermeasure development, implementation planning, action plan execution, and follow-up and evaluation.

Q: What is the purpose of the problem identification and description step?

A: The problem identification and description step is crucial for clarifying the problem, its impact, and the desired outcome. It helps establish a common understanding among the team members and ensures everyone is working towards the same goal.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

LEI's Learning Portal

Developing structured problem-solving and leadership skills using a3 thinking: managing to learn remotely.

Join us for a seven-week learning experience and learn how to use the A3 methodology to solve important business problems. Optional one-on-one coaching package also available.

Today's unprecedented challenges require superior problem-solving skills not only from you as a leader but everyone you manage.

Learning objectives.

What makes the A3 problem-solving approach so powerful is that it is a complete process -- a way of thinking, leading, communicating, learning, getting things done, and developing an entire organization of problem solvers.

Select, define, clarify and investigate a real problem from work.

Clarify problem situations and define problems as gaps in performance.

Visualize work processes and focus on the problems in work methods that are affecting performance.

Investigate and confirm underlying causes and analyze barriers to improvement.

Identify, evaluate and lead in the selection of countermeasures.

Lead planning for implementation of countermeasures and follow-up to resolve problems in execution and reflect for organizational learning

The A3 format puts the problem, analysis, corrective actions, and an action plan on a single sheet of large (A3) paper, often with the use of graphics.

What's Included?

- 14 hours of live, online interaction

- Feedback from facilitators and peers

- Assignments between live sessions to begin applying the lessons and complete your A3

- Opportunities to practice discrete skills with live feedback

Cohort beginning September 17

12:00 PM - 2:00 PM ET

- Session 1: September 17

- Session 2: October 1

- Session 3: October 15

- Session 4: October 29

- Session 5: November 12

- Session 6: December 3

- Session 7: December 17

Optional One-on-One Coaching Sessions

Achieve an even deeper level of learning by taking personal coaching sessions with instructor David Verble, who has 30 years of experience teaching and coaching the A3 management process to leaders and managers.

- completion of the problem situation/current situation section;

- completion of the analysis section and whole left side;

- creation of recommended countermeasures and an implementation plan at the start of the right side.

Personal coaching gives you individual "just-in-time" assistance on your challenges in a private, completely safe online space to share and ask questions.

Schedule Overview

The seven sessions are hosted over 14 weeks, with one to two hours of assignments in between and optional individual coaching sessions available for an additional $499.

Who Should Attend

- Managers, supervisors or executives who want to develop the structured problem-solving, hypothesis-testing, and fact-based, decision-making skills of teams

- Continuous improvement or change management professionals involved in leading major change improvement initiatives

- HR professionals who wish to develop a curriculum and teach introduce structured problem solving and fact-based decision-making skills within their organization

Group Discounts

Engage your whole team with our group discounts.

Technology Used

Please click here to run through our technology check before registering for this course.

- Communication Channel: A ll our documents and assignments will be hosted on a browser-based platform. By logging onto our e-learning website you will be able to view all related materials, announcements, and zoom links.

- Zoom : W e will host our live meetings on zoom. You will receive an invitation with the meeting link.

Cancelation Policy

You can cancel your registration for online/live-streaming workshops 2 weeks prior to the start date of the course for a full refund. A cancellation occurring within 2 weeks of the workshop dates will be subject to a $350 cancellation fee. Once you have attended a workshop session, you cannot cancel your registration. To cancel please call LEI at (617) 871-2900 or email [email protected] .

Instructor(s)

LEI Faculty David Verble

Karen Gaudet

Interested in bringing this workshop to your company.

LEI will teach any of our workshops or develop a customized program to build capability in your team.

Whether you need coaching to develop organizational leadership effectiveness, frontline management proficiency, work team or business-unit process improvement capability, or to achieve an organization-wide transformation, LEI can customize a learning plan to meet your needs. Talk with a Coach to learn more »

Stay Connected

Subscribe to LEI's newsletters on lean thinking and practice.

Continuous Improvement Toolkit

Effective Tools for Business and Life!

A3 Thinking: A Structured Approach to Problem Solving

- 5 MINUTES READ

Also known as A3 Problem Solving.

Variants include 8D and CAPA.

A significant part of a leader’s role involves addressing problems as they arise. Various approaches and tools are available to facilitate problem-solving which is the driving force behind continuous improvement. These methods range from the advanced and more complex methodologies like Six Sigma to the simpler and more straightforward A3 thinking approach.

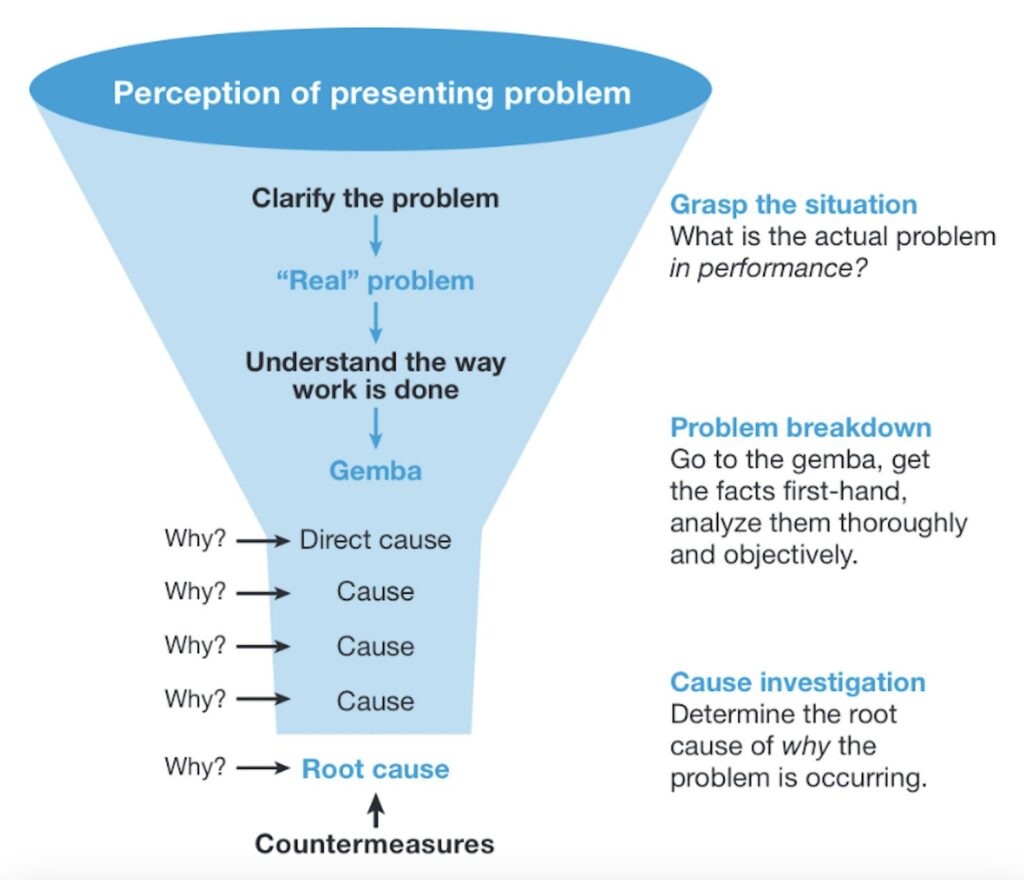

The power of the A3 approach lies in its systematic and structured approach to problem-solving. Although it appears to be a step-by-step process, A3 is built around the PDCA philosophy. It relies on the principle that it is much better to address the real root-cause rather than trying to find a solution. Hence, it’s important not to jump to the solution when solving a problem as it is likely to be less effective.

A3 thinking provides an effective way to bring together many of the problem-solving tools into one place. For example, techniques such as the 5 Whys and fishbone analysis can be used during the ‘Analysis’ stage to help identifying the root causes. Additionally, visual aids and graphs are highly recommended in the A3 report, as they are more effective than text in communicating ideas and providing concise project updates.

A3 thinking involves the practice of consolidating the problem, analysis, countermeasures, and action plan onto a single sheet of paper, commonly an A3-sized sheet. This brief document serves as a summary of the project at hand and is regarded as a valuable storytelling tool for project communication. Utilizing the A3 approach doesn’t require any specialized software or advanced computer skills. You may however use readily available A3 templates , or rely on basic tools such as paper, pencil and an eraser as you will need to erase and rewrite several times.

One of the characteristics of the A3 approach is that it does not get into specific details. Detailed documents are usually attached to the A3 report to prevent overwhelming the reader with an excess of information.

The A3 process is typically structured in multiple stages based on the PDCA model. The primary focus is on developing understanding of the current situation and defining the desired outcome before thinking about the solution. While the exact number of stages may vary depending on the preference of the company, what truly matters is adhering to a structured approach to problem-solving.

A3 Seven Stages Model

An A3 process is often managed by an individual who should own and maintain the A3 report. This individual takes the lead in steering the process, facilitating team involvement, and preparing the A3 report with team input. One of the most common models for A3 thinking is the seven stages model which is described in the following.

1. Background – The first step is to identify the business reason for choosing this problem or opportunity. In this stage, you need to identify the gap in performance and the extent of the problem.

2. Current situation – The purpose of this stage is to document the current state of the problem. You may need to refer to the process map or go to the Gemba to truly understand the current situation.

3. Target – The purpose of this stage is to define the desired future state. Clearly identify the expected benefits from solving the problem, the scope, and the key metrics that will help measure the success of the project.

4. Analysis – The objective of this stage is to conduct an in-depth analysis of the problem and understand why it’s happening. It might involve tools like the 5 Whys and cause-and-effect analysis, as well as advanced statistical methods.

5. Countermeasures – Countermeasures are the actions to be taken to eliminate root causes or reduce their effects. The team should brainstorm and evaluate possible countermeasures based on the analysis conducted earlier.

6. Implementation Plan – To achieve the target, develop a workable plan to implement the countermeasures. Gantt charts are great ways to manage implementation plans very simply and easily. Once the action plan is finalized, the team should begin working on the activities needed to implement the countermeasures.

7. Follow-up – The final stage involves evaluating the implementation of the plan and the results achieved. Follow-up actions are important to ensure the benefits extend beyond the project’s completion.

A3 thinking is considered to be the practical form of the PDCA model.

There are many online templates that can be used to manage your problem-solving efforts. One of the simplest and most straightforward ways is to use this A3 problem solving template .

Wrapping Up

A3 thinking represents a logical and structured approach for problem solving and continuous improvement. This approach can be used for most kinds of problems and in any part of the business. Originating from the Toyota Production System (TPS), it has been adopted by many Lean organizations around the world.

A3 thinking not only provides a systematic approach for problem-solving. The development of a continuous improvement culture is at the core of A3 thinking. It has become one of the most popular Lean tools today where people and teams work together to solve problems, share results and learn from each other.

Other Formats

Do you want to use the slides in your training courses?

A3 Thinking Training Material – $18.85

Related Articles

Project Charter

Gantt Chart

Related Templates

A3 Problem Solving

Written by:

CIToolkit Content Team

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Culture , Lean Training , Lean Wiki , Tools

A Deep Dive into the A3 Problem-Solving Approach

- 11 mins to read

- June 20, 2023

- By Reagan Pannell

In today’s fast-paced and fiercely competitive business world, organisations must find ways to continuously adapt, evolve, and excel. Amidst the myriad methods and techniques for achieving improvements and driving continuous improvement, few have proven as profound and transformative as Toyota’s A3 problem-solving approach.

A significant driving force behind the company’s rise to global prominence, the A3 process fosters a culture where problems are embraced as opportunities for growth and learning. In this article, we’ll explore the origins and underlying principles of the A3 approach and uncover the secrets to its success in unlocking the power of improvements.

Understanding the A3 Approach

The A3 methodology is an integral part of the Toyota Production System (TPS), a set of principles and practices that have shaped the company’s approach to manufacturing, management, and continuous improvement over the years. Named after the A3 sheet of paper that was historically used to capture the plan, analysis, and follow-up on a single page, the A3 process represents a simple, yet powerful, tool for addressing complex challenges and discovering lasting solutions.

At its core, the A3 approach is rooted in three key elements:

1. Thorough problem analysis: The foundation of the A3 process lies in digging deep to diagnose the true nature and root cause of an issue, rather than jumping to hastily devised fixes that merely address symptoms.

2. Structured documentation: The A3 report serves as both a communication tool and an iterative planning device, with each section building on the previous ones to guide problem solvers through a comprehensive analysis, solution development, and execution process. It’s the foundation of good continuous improvement.

3. Cyclical learning and improvement: Leadership and employees alike are encouraged to commit to hypothesis-driven inquiry, observation, experimentation, and reflection, leading to a culture that actively seeks and leverages opportunities for growth by solving problems.

How to Implement the A3 Process in Your Organisation

The Lean Thinking A3 approach can be distilled into seven essential steps:

1. Identify the problem:

Clearly articulate and define the issue at hand, avoiding the temptation to jump to solutions or assume important facts to be self-evident..

When identifying the problem, it is important to ensure that all relevant stakeholders in the organisation are consulted. This helps to ensure that the issue is accurately described and understood from multiple perspectives. A thorough problem analysis should also include conducting research into possible causes or root issues, and clearly documenting any observed symptoms of the problem. Additionally, it is essential to identify any major risks associated with not finding a solution and recognise any constraints (both external and internal) that may exist which could limit potential solutions. Lastly, it is important to consider any potential opportunities which may arise from addressing the issue that may have been overlooked at first glance. This is the problem statement part which is a critical component that identifies the difference between the current condition and the target condition.

At this stage, we are not looking at how to solve problems being faced or at the potential solution to solving problems. It’s about developing a good understanding of how the actual results differ from the expected results and providing an in-depth systematic approach to process improvement and developing problem-solving skills.

2. Establish the context and background:

Provide a high-level overview of the problem, describing the stakeholders involved, relevant data, and the broader organisational context in which the challenge has arisen..

It is important to ensure that all stakeholders are properly considered when identifying any potential solutions as their perspectives can play a vital role in determining an effective solution. All related data should be thoroughly analysed to understand the full scope of potential solutions. This includes resources, costs, timelines, and any legal or regulatory issues that may need to be considered. Additionally, it is important to consider how well-proposed solutions fit within existing organisational policies and procedures as this could impact implementation success. Finally, understanding how proposed solutions would interact with other initiatives or processes currently taking place in the organisation can help inform decisions about whether or not they are viable options. It may include conducting some value stream mapping to dig deeper into the current state.

It is important to fully explore any underlying factors that may be contributing to the issue at hand and ensure in-depth problem analysis. This includes looking deeper into existing systems, structures, and processes related to the problem in order to identify potential areas of improvement or optimisation. Additionally, it is essential to consider any relevant industry trends or external influences that could impact how the problem manifests within the organisation.

When analysing a problem, collecting data from various sources is important to get a more comprehensive understanding of how a particular issue can be addressed. This includes mapping the current process using the VSM, SIPOC, Process Mapping or Flowcharting techniques. Additionally, interviews and surveys can be conducted with stakeholders to gain insights into how they perceive the issue and their perspectives on potential solutions. Lastly, it is important to observe any real-world activities related to the problem to uncover key areas where time, effort, resources, money etc is being wasted. This is the time improvement that may not have been identified otherwise.

GB MASTERCLASS COURSE

Get access to our free gb mastercourse classes, free course previews, fundamentals of lean.

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LEAN SIX SIGMA GREEN BELT

Get 3-days free access to our green belt course, accelerate your career, 3. set a goal:, now that you have identified the problem and outlined the relevant context, it is time to set a project goal or outcome..

This involves clearly articulating the desired state of affairs and any key deliverables of the proposed solution. Whether it is reducing operational costs, increasing efficiency, improving customer experience, or something else entirely – defining specific objectives with measurable metrics can help ensure that project teams stay focused and remain aligned on their ultimate destination.

At this stage, it is also important to consider how long it will take to reach the desired outcome. Establishing an implementation timeline will help safeguard progress and provide a framework for tracking results along the way. Setting milestones for achieving particular goals at certain points in time can be especially helpful in keeping teams accountable throughout the process. Additionally, having a plan for evaluating success after reaching the end target will allow stakeholders to gain further insights into how effective their approach has been in addressing underlying problems, as well as how well-proposed solutions have fared once implemented.

4. Investigate root causes:

Use a variety of techniques (e.g., the 5 whys, fishbone diagrams, pareto charts) to probe the problem’s underlying causes and avoid settling on proximate reasons..

The process of identifying root causes is essential when using data-driven tools. We always want to find the simplest root cause approach.

One of the most widely used methods for root cause analysis is the ‘5 Whys’ technique. This method involves asking a series of ‘why’ questions to determine the underlying cause of a particular symptom or issue. The goal is to keep asking “Why?” until you reach an answer that can provide insight into how to address the problem and prevent it from occurring in the future.

Another commonly used tool for root cause analysis is the fishbone diagram (also known as Ishikawa diagrams). This approach involves visualising all potential causes which could be causing a symptom or issue in a logical format, allowing users to identify patterns and uncover links between root causes and their respective effects. This technique can be helpful in identifying and focusing on key areas for improvement, as well as helping to identify interdependencies between components within an organisation’s systems.

Finally, Pareto Charts are useful for analysing data collected from surveys, interviews, observations, etc., concerning the severity or frequency of occurrence. This type of chart helps users quickly identify which factors are contributing most significantly towards an issue, allowing them to focus resources towards addressing those areas first and foremost. Additionally, Pareto charts can also be used to prioritise different solutions based on their estimated effectiveness in addressing an issue.

In conclusion, understanding the root cause of an issue through rigorous techniques such as 5 Whys, fishbone diagrams, and Pareto charts provides invaluable insight into how best to address it effectively while preventing it from reoccurring in the future. By leveraging these tools along with other data-led approaches such as process mapping and flowcharting, organisations can ensure that any proposed solutions are well-informed by both qualitative and quantitative data sources as well as ensure they are building consensus across the entire organisation.

5. Countermeasures:

Identify the right countermeasures (corrective actions) to implement that will directly impact the root causes identified..

Brainstorming is a useful tool for identifying potential improvements. It involves coming up with ideas and solutions in an open and collaborative manner, without judgement or criticism. By allowing team members to share their thoughts freely, brainstorming can help uncover innovative solutions that may have otherwise gone unnoticed. Additionally, looking at how waste reduction, flow and pull can be used to improve processes can also provide valuable insights into where improvement opportunities lie.

Brainstorm potential solutions that directly target the root causes and create detailed action plans for implementation, complete with assigned roles, responsibilities, and timelines.

Once the countermeasures are identified, it is important to design an implementation plan and assign roles & responsibilities. This will help ensure that all stakeholders understand their part in the implementation and can work together to achieve the desired outcome. Additionally, it is important to track progress along the way – setting measurable milestones that can be tracked against goals established during the initial problem-solving phase will help keep teams accountable and allow for course corrections if needed.

By utilising A3 Problem Solving Tools such as a template, organisations can easily document and share their analyses with relevant stakeholders throughout each stage of the project. Having detailed record-keeping like this also helps teams stay on target over time while providing insights into how proposed solutions may need to be re-evaluated down the line. This implementation plan provides the entire organisation with a clear project status on a one-page report.

6. Evaluate the results:

Measure the impact of your countermeasures against the problem, using well-defined success criteria, key performance indicators, or other relevant metrics..

Once the countermeasures have been implemented, it is essential to measure and evaluate their success. This can be done by tracking performance against the initial objectives established during the goal phase, as well as establishing key performance indicators to gauge how well the proposed solutions have fared.

Additionally, stakeholders should also consider conducting a post-implementation evaluation in order to assess how successful their approach has been in addressing underlying issues and determining what lessons can be learned from the experience. This will enable teams to identify strengths and weaknesses within their existing processes and make any necessary adjustments going forward. By understanding the outcomes of their improvements, organisations are able to gain valuable insights into how well they’ve succeeded in achieving their goals and ensure continued success moving forward.

Once the countermeasures have been implemented and their success measured, it is important to compare the results against the initial objective. This can be done in a variety of ways, including graphical analysis such as charts, process maps or flow diagrams. Graphical analysis helps to visualise the differences between results achieved before and after the implementation of new measures in a meaningful way. It also provides an increased level of clarity when assessing whether the desired outcomes have been achieved or not.

Process maps can be useful in understanding how changes made during the improvement phase have impacted processes within an organisation. By mapping out existing processes and then comparing them against those following implementation of countermeasures, teams can easily pinpoint where improvements were made and analyse how they led to improved performance overall.

Charts, on the other hand, enable users to quickly identify trends that may have emerged from data collected during the project. For example, if performance metrics are tracked before and after countermeasures are implemented, users can use charts and graphs to more clearly observe any patterns that may indicate an improvement or regression in performance over time – providing further insights into which areas need further attention or adjustment moving forward.

Finally, dashboard views provide an effective means of displaying results at a glance while highlighting any anomalies that might warrant further investigation. Dashboards allow stakeholders to gain access to important information quickly and easily while also helping them keep track of progress towards goals set out during initial problem-solving phases. Additionally, because dashboards support data visualisation capabilities they offer a highly interactive user experience which can help teams understand underlying trends with greater clarity and precision.

7. Standardise and share:

If a countermeasure proves successful, integrate it into the organisation’s standard operating procedures and share it with other teams as a best practice..

Once the countermeasures have been successfully implemented and measured against the initial objectives, these changes need to be integrated into the organisation’s standard operating procedures (SOPs) and shared with other teams as best practices. This will ensure that any improvements made during the problem-solving phase are consistently applied across all teams within the organisation.

In order to ensure that these improvements become part of the organisation’s long-term strategy, process maps should be updated to reflect the new improved way of working. Process maps provide a visual representation of how workflows are structured within an organisation, and by updating them in line with newly-implemented countermeasures, organisations can ensure that their processes continue to remain up-to-date and efficient moving forward. It may also be necessary to build a follow-up plan if not all tasks are fully completed as well as develop a Lean-focused PDCA cycle to ensure long-term effective collaboration on the solutions that were implemented.

Process documentation should also be updated in order to keep track of changes made during problem-solving. By documenting not just the solutions that were proposed but also why they were proposed, teams can gain valuable insights into their decision-making process which they can leverage for similar future problems.

Furthermore, it is important to update key performance indicators (KPIs) to accurately reflect any progress made during problem-solving. By tracking performance against objectives established before and after countermeasures were implemented, organisations will be able to identify any areas that may still need improvement or require further adjustment going forward. Additionally, tracking KPIs over time will help teams understand whether or not their current strategies are leading them towards meeting their goals in a timely manner or if additional measures may need to be taken in order to achieve desired results more quickly.

Finally, organisations should share successful solutions with other teams in order to promote collaboration and knowledge sharing amongst stakeholders throughout different parts of the business. This will allow for ideas generated through one team’s problem-solving efforts to benefit multiple departments – helping foster creativity and innovation while ensuring that everyone is on board with necessary changes being made throughout the organisation. The last step is key to Toyota’s PDCA management system designed for the entire organisation.

By breaking down the problem-solving process into these seven discrete stages, the A3 method offers practitioners a comprehensive, end-to-end framework for tackling complex challenges and driving improvements in any organisation.

- Corporate Training

- Courses for Individuals

Training the team on A3

To get A3 started, everyone in the entire organisation needs to learn how to use this single-sheet or single-page document. This means training people across all parts of the company so that everyone knows how to use the A3 Problem Solving Tool and A3 template. Training will help make sure that everyone follows a structured approach when using A3.

Getting the organisation fully onboard with A3 Problem Solving is not an easy task and will require a dedicated effort to ensure its successful implementation. To this end, it is important to start with specific areas of the business – whether it be operations, finance or marketing – by setting up targeted training sessions for both operational teams and senior managers. This will help everyone understand how and why A3 is used, as well as the potential benefits it can bring to their business.

Once everyone has mastered the basics of working with an A3 template, companies should look to regularly review and evaluate its effectiveness. This could include setting up quarterly reviews or running workshops where teams discuss successes and areas for improvement when using the A3 tool. Doing this will ensure that any issues are identified early on, allowing the team to quickly adjust accordingly.

At Leanscape, we understand that transitioning to A3 Problem Solving can be a daunting task. With our team of specialists, we can provide your teams with the necessary training and coaching to ensure that they are able to adapt quickly and efficiently. Our comprehensive approach to A3 will equip your team with the knowledge and skills needed to successfully use this powerful tool for improving performance in all areas of your business.

We are committed to helping you develop a culture of continuous improvement within your organisation by teaching best practices and providing guidance through every step of the problem-solving process. Through our specialised training programs, we will help your teams learn how to use the A3 template more effectively, as well as how to interpret data visualisations quickly and accurately – enabling them to take action swiftly when required. Our experienced coaches will also share insights from industry experts on how best to integrate countermeasures into standard operating procedures (SOPs) and process maps, keeping up-to-date with industry trends in order to stay ahead of the competition.

By leveraging Leanscape’s expertise in A3 Problem Solving, you can rest assured knowing that your team is in good hands. Our team is dedicated to providing you with the support needed for successful implementation so that you can achieve sustained performance improvements over time.

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

The implementation of A3 Problem Solving provides a comprehensive framework for organisations looking to successfully address complex problems in an efficient and cost-effective manner. By breaking down the problem-solving process into seven distinct stages, users can structure their approach and track the progress of their countermeasures over time.

In order to ensure successful implementation, organisations should dedicate time towards training their teams on how to use the A3 Problem Solving Tool and A3 template. This will give everyone a solid foundation for carrying out future problem-solving activities more effectively, as well as provide insights into the effectiveness of certain countermeasures over time.

Through Leanscape’s specialised training programs, you can ensure that your team is fully equipped with the necessary skills to successfully adopt and incorporate A3 Problem Solving into all areas of your business. Our experienced coaches are committed to helping you develop a culture of continuous improvement within your organisation – providing guidance through every step of the process

Final Thoughts

The A3 approach is an invaluable tool for unlocking the power of improvements within any organisation. By leveraging its structured framework and cyclical learning approach, businesses can remain agile and responsive to ever-changing conditions, allowing them to navigate change more successfully and emerge stronger than ever before. Ultimately, this makes Toyota’s A3 problem-solving process one of the most effective ways to ensure long-term success in today’s fast-paced and competitive market.

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, principe 8: use throughly tested technology | principles of lean, 12 best lean management books, 2 proportion test: the basics, principle 7: visual management in lean | the 3 second rule, newsletter | porters five forces and how to stand out, a beginner’s guide to the mood’s median test in lean six sigma, understanding takt time | what is takt time, the power of hansei: why japanese business leaders swear by this concept, the vital role of successfully adopting lean in driving operational improvement, time thieves: how time slips away, how business and management are connected.

- | lean , lean thinking , problem solving , toolkit , tools

Related Articles

Is problem solving a skill how to improve your problem-solving skills, overall equipment effectiveness – how does it work, 5 bullet friday lean thinking newsletter | 8th sept 2023, an overview of the pugh matrix: what is it and how does it work, sources of measurement error – bias and precision, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

- Learn center

- Project management

How to use Toyota’s legendary A3 problem-solving technique

Georgina Guthrie

February 21, 2020

If you came home one day and found your kitchen taps on full-blast and your house full of water, what’s the first thing you’d do? Grab a bucket and start scooping — or turn off the tap?

When it comes to problem-solving, many of us take a rushed, reactionary approach rather than fixing the issue at the source. So in other words, we see the water, panic, and start scooping. If this sounds like something you’ve done recently, then don’t feel too bad: when the pressure’s high, we often jump towards the quickest fix, as opposed to the most effective one.

This is where the A3 technique comes in. It’s a problem-solving approach designed to efficiently address the root cause of issues.

What is the A3 technique?

The A3 technique is a structured way to solve problems. It’s part of the Lean methodology , developed by Toyota back in the mid-’40s. This doesn’t mean you need to implement a Lean way of working to take advantage of this process — it can work as a standalone exercise.

Granted, A3 isn’t an inspiring name, but the story of its origins is actually pretty interesting. Rumour has it that Taiichi Ohno, inventor of the Toyota Production System, refused to read past the first page of any report. In response, his team created A3 address and summarize problem-solving on one side of A3-sized paper. The A3 technique played a huge part in Toyota’s success and all kinds of industries have since adopted it. Here’s how to get started.

How to solve a problem with A3

The first thing to remember is this: A3 is collaborative and relies on good communication. It’s not something you should do by yourself.

There are three main roles involved:

- Owner (that’s you or someone under your charge)

As you’ve probably guessed, these aren’t roles that already exist in your company; you must create them for the purpose of this process. Here’s what they mean.

The owner is responsible for leading the exercise. They are the lynchpin between the two other roles, fostering good communication and keeping documents up to date. It’s tempting to think of the owner as the head of this trio, but that’s not true: everyone is equal here.

The mentor is someone with solid problem-solving experience. It’s their job to coach the owner and steer them towards finding a solution. It’s not their job to find the answers themselves.

And finally, there are the responders . This is someone (or a group of people) who have a vested interest in the outcome of the A3 project. Responders might include the client, stakeholders, or managers. A potential problem here is gaining access to them: if you work somewhere with a strict hierarchy — and you’re somewhere near the bottom of that structure — you may face challenges. There’s no easy way around this. Essentially, you need your organization to support this way of working and make it easy for you to access those at the top if needed.

How to create an A3 report

True to its origins, the A3 report is a one-page document. It typically contains 5-7 sections that systematically lead you towards a solution. These are the most commonly used steps, but feel free to modify them.

- Background: Explain your project in a few sentences, including its context.

- Problem statement: Explain the current problem. You can use process mapping to see the different tasks that surround the issue. This isn’t essential, but it will make it easier for you to locate the root cause.

- Goals: Define your desired outcome, and include metrics for measuring success. You won’t know everything until you reach the end, so you may find you need to come back and refine stages 1-3.

- Root cause analysis: This is a big stage of the process. You need to work out what you think the root problem is. You can use different methods to help you here, including 5 whys or a fault tree analysis .

- Countermeasures: Once you’ve worked out your root cause, you can start proposing solutions.

- Implementation: Work out how you’ll implement these solutions, including an action list with clearly defined roles and responsibilities. Project management software is a useful tool here because it can help everyone on the team track each other’s progress in real-time.

- Follow-up: Using your metrics for success, decide whether the problem was solved. Report your results back to the team/organization. In the spirit of Lean (continuous improvement), you should go back and modify your plan if the results weren’t as expected. And if they were, you should make this process the new standard.

Final thoughts

A3 is an efficient, methodical way to solve problems at their source. When issues rear their head, rising stress can lead people to panic. Having a clearly designed system in place to guide you towards a solution minimizes the chances of people settling for a ‘quick fix’ or failing to act altogether.

Beyond being a guiding light in times of pressure, A3 is a great team-building exercise because it encourages individuals to work together towards a common goal — across all areas of the organization. Combine this with collaborative tools designed to help teams track progress and work together more effectively, and you’ll be unstoppable.

Solve problems like a pro with Root Cause Corrective Action

Lean to Six Sigma: process improvement methodologies explained

Subscribe to our newsletter.

Learn with Nulab to bring your best ideas to life

- MY LCI Login

- LCI Design & LCI Engineering Design Award

- Our Mission & Vision

- Our Strengths

- History of LCI

- How We Serve

- Board of Directors

- LCI Congress 2024

- Lean in Design Forum 2024

- Respect For People

- Communities

- New to Lean

- Learn by Pathway

- For Designers

- For Constructors

- Field Crew Huddle

- Assessments

- Classroom Learning

- Instructor Program

- LCI Publications

- Learning Videos

- Partner Programs

- Simulations

- Certification FAQs

- Certification Practice Quiz

- Designation Directory

- Lean Construction

- Lean Design

- Lean Project Delivery

- What is Lean?

- Founder’s White Papers

- Lean Construction Journal

- LCI Research

- Newsletter Archives

- Past Event Presentations

- Blog & Buzz

- Lean Consultant Members

- Member Directory

A3: Thinking, Reports, Examples & Templates

A3 thinking, an introduction to a3.

In the design and construction industry – as in all industries – complex problems arise daily. Each project contains hundreds of decisions containing thousands of variables, and sorting them out to arrive at the best outcome is critical.

A3 problem solving provides teams with a strategy to effectively and efficiently deal with problems that they encounter and decisions that need to be reached. In true Lean fashion, A3 process improvement brings the entire team into the collaborative problem-solving process and allows teams to embrace out-of-the-box solutions.

What is A3?

An A3 is a one-page report prepared on a single 11 x 17 sheet of paper that adheres to the discipline of PDCA thinking as applied to collaborative problem solving, strategy development or reporting. The A3 includes the background, problem statement, analysis, proposed actions, and the expected results.

The History

A3 thinking was developed by Toyota in the 1940s. Toyota believed that any problem should be capable of being explained and solved using one sheet of paper (an 11 x 17 sheet being the largest sized paper that is capable of being faxed and closest in size to the traditional A3).

The company also believed that if a problem is too complex to fit onto an A3 report, it should be broken down into smaller bits that would be solved individually. If your problem cannot fit onto an A3, you should reconsider the scope of what you are hoping to accomplish.

Who Uses A3 Strategies?

Today, A3 strategies are deployed across various industries that employ Lean thinking such as:

- Design & Construction

- Manufacturing

- Project Management

- Engineering & Architecture

- Service Industries

LCI’s Meaning of A3

A3 thinking is an extremely useful tool when utilized correctly. By distilling the entirety of a problem on a single sheet of paper, A3 Lean thinking forces team members to collaborate and rationalize through the problem solving process. A3 thinking makes for more effective problem solving and produces written explanations that can then be passed on to senior management. An effectively completed A3 report will also build management’s confidence in the team and its ability to solve problems.

A3 Reporting

A well-written A3 report should show and explain the consideration that went into the counter-measure to the problem listed. Properly executed plans include the input of team members from all across the stakeholder spectrum and should allow members to emerge as leaders in its problem solving. A3 papers can also be referenced later, allowing the lessons learned during the process to be shared with future project teams.

Understanding A3 Thinking

A3 thinking does not provide a solution to the problem your team is facing. Rather, it guides your team’s process to help it reach the best possible countermeasure with the tools it has at its disposal.

An A3 report is to be filled out by one person on the team – the “champion” – who will gather assessments and intel from other members in a collaborative fashion. Bringing all of the knowledge and expertise of the team to bear when solving a problem is the best way to come to a satisfying outcome.

Problem Solving: An A3 Process

A3 thinking allows for many different types of decision-making. But ultimately, all decisions are fundamentally a form of problem solving. For example, A3 thinking can be deployed to guide the team in optimizing decisions during the design phase, or for solving a constructability challenge.

The First Step to A3 Thinking

The first step of the A3 process for problem solving is to correctly identify the problem. From unexpected lead times on materials to communication breakdowns among design teams, “problems” are in no short supply in the design and construction industry. Before engaging in A3, ask yourself the following questions about the problem you are working to solve.

Questions to Facilitate the Process

- What are you trying to address or solve?

- What is the current situation?

- What are clear Conditions of Satisfaction (CoS) I can develop?

- Where can I brainstorm and analyze the 5 whys/root cause ideas?

- What’s a recommendation I can put forth?

- What is my plan to implement the recommendation above (if applicable)?

State plan to check and adjust using the PDCA cycle.

More on the PDCA Cycle

PDCA stands for Plan, Do, Check, Adjust. Explore each element of this acronym for more information about how it supports both the problem solving questions above as well as A3 problem solving as a whole.

Identify an issue in your process and exercise continuous improvement by planning your course of change.

Perform your case study by applying the corrective actions outlined in the “plan” stage in an experimental manner.

Follow the performance of your experiment and measure it to determine whether it is having the desired effect.

If your plan worked, implement the change to the necessary areas of your process. If it did not, determine what you will do differently next time and repeat the cycle.

A3 Reports for Solutions

While A3 reports broadly follow the PDCA cycle, the actual journey of an A3 process is a bit more granular. Let’s analyze the various steps and sections of an A3 report.

Describe the problem, theme, or issue. List out all of the details including the champion’s name, date, and the names of all of the collaborators who will be helping with the report.

Establish the business context & importance. Provide additional information on the problem being addressed.

Current State

Describe what is currently known about the problem. Note potential variables and roadblocks that may stop your team from solving this problem and additional information you hope you acquire.

Future State or Goal

Identify the desired outcome for your experiment. Identify the Conditions of Satisfaction (CoS) for the project.

Analyze the situation and underlying cause.

Recommendation

Provide a recommendation for process improvement that your team can implement for the future.

Create a follow-up/review process.

A3 Examples

A3 thinking is frequently applied in Lean design and Lean construction during all phases of the process for the purposes of making sound decisions. In the example below, A3 thinking is applied to the process of learning Lean design and construction techniques.

A3 Template

The Lean Construction Institute seeks to educate companies all throughout the design and construction industry on Lean practices and methods. Here is our A3 template which you can use to guide your decision-making processes.

A3 Training

The Lean Construction Institute offers A3 training as well as tools , events , education , and networking opportunities for Lean practitioners in design and construction all around the world. Whether you’re a Lean expert or are just learning about Lean for the first time, LCI can provide the tools you need for problem solving and continuous improvement in your business.

Lean Assessments

How strong is your Lean knowledge? Take a Lean assessment to determine your current state so you have a baseline for improvement. Lean assessments are available for individuals, teams, and organizations alike. Whether you’re new to Lean or are an experienced Lean practitioner, Lean assessments are a great way to get started at LCI!

William R. (Bill) Seed, Executive Editor

Executive Editors: Kristin Hill, Katherine Copeland and Christian Pikel

More lean topics.

From 5s to IPD, explore more popular Lean design and construction topics below.

- A3 Problem Solving

Sales Acceleration Workshop

Lorem ipsum dolor sub title..

Do you know the best ways to solve your problems? Are you sometimes stumped and unable to move forward? That’s why the Michigan Manufacturing Technology Center is here for you! Plainly stated, WE HELP YOU LEARN HOW TO FIND SOLUTIONS.

Problematic? Our approach is Automatic! Solving problems is all in a day’s work for many of us. However, are we analyzing the symptoms of the problem correctly, with an eye to hidden elements? Are we handling the situation in the most efficient, cost-effective way? In short, do we really know what we are talking about and doing?

These are the problems that can cause managers to lose sleep, and cause their employees to doubt the efficacy of decisions that manager is making.

The Michigan Manufacturing Technology Center knows that successful manufacturers constantly focus on improving quality and on-time delivery while attempting to reduce operating costs. Resources are always in short supply, so effective, rapid, real-time problem-solving methods are critical. The A-3 technique, a structured problem-solving approach, teaches employees how to rapidly address manufacturing problems, effectively communicate solutions, and monitor results.

This technique seeks to clearly define the problem in measurable terms, uncover potential root causes, determine the true root cause or causes, analyze alternative answers, develop implementation plans, and communicate key performance indicators. All information is recorded in a document printed on 11-by-17-inch paper, the size designated “A-3” by ISO 216.

With the Michigan Manufacturing Technology Center, the A3 Process is a successful and pragmatic problem-solving technique for creating sustainable organizational change. It is also a great plan of attack for an aggravating, stubborn and ongoing problem that prevents it from growing into a major catastrophe! Register for The Center’s A3 Problem Solving Seminar by phone, fax or email today and . . . Sleep well tonight!

Upcoming Classes

June 04, 2024 8:00 AM- 12:00 PM 45501 Helm St. Plymouth, MI

Register Now

June 19, 2024 9:00 AM- 1:00 PM 6800 Browns Lake Rd. Jackson, MI

September 16, 2024 8:00 AM- 12:00 PM 45501 Helm St. Plymouth, MI

November 11, 2024 8:00 AM- 12:00 PM 45501 Helm St. Plymouth, MI

- Virtual Classes

- Cybersecurity

- Food Safety

- Industry 4.0

- Leadership / Culture

- 5S Workplace Organization Simulation

- 5S/Visual Management

- Advanced Problem Solving: Lean Six Sigma Yellow Belt (CEUs: 2.1 | PDCs: 21)

- Digital 5S Document Management

- Lean Applications Workforce Training (CEUs: 3.5)

- Lean Manufacturing Champion Certification with Kaizen

- Lean Manufacturing Practitioner

- Lean Manufacturing Simulation

- Lean Office Champion (CEUs: 2.1 | PDCs: 21)

- Lean Office Champion Certification With Kaizen

- Lean Office Practitioner

- Lean Office Simulation

- Lean Simulation

- Lean Six Sigma Green Belt (CEUs: 5.6)

- Mistake-Proofing

- Power of Lean Series

- Standard Work

- Total Productive Maintenance/Quick Changeover

- VIRTUAL CLASS: A3 Problem Solving

- VIRTUAL CLASS: Lean Manufacturing Champion Certification

- VIRTUAL CLASS: Lean Manufacturing Practitioner

- VIRTUAL CLASS: Lean Office Practitioner

- VIRTUAL: Principles of Biomanufacturing

- Quality Management

- Safety/Environmental

- Specification Management

- Supply Chain

- Open access

- Published: 17 February 2022

Effectiveness of problem-based learning methodology in undergraduate medical education: a scoping review

- Joan Carles Trullàs ORCID: orcid.org/0000-0002-7380-3475 1 , 2 , 3 ,

- Carles Blay ORCID: orcid.org/0000-0003-3962-5887 1 , 4 ,

- Elisabet Sarri ORCID: orcid.org/0000-0002-2435-399X 3 &

- Ramon Pujol ORCID: orcid.org/0000-0003-2527-385X 1

BMC Medical Education volume 22 , Article number: 104 ( 2022 ) Cite this article

31k Accesses

78 Citations

10 Altmetric

Metrics details

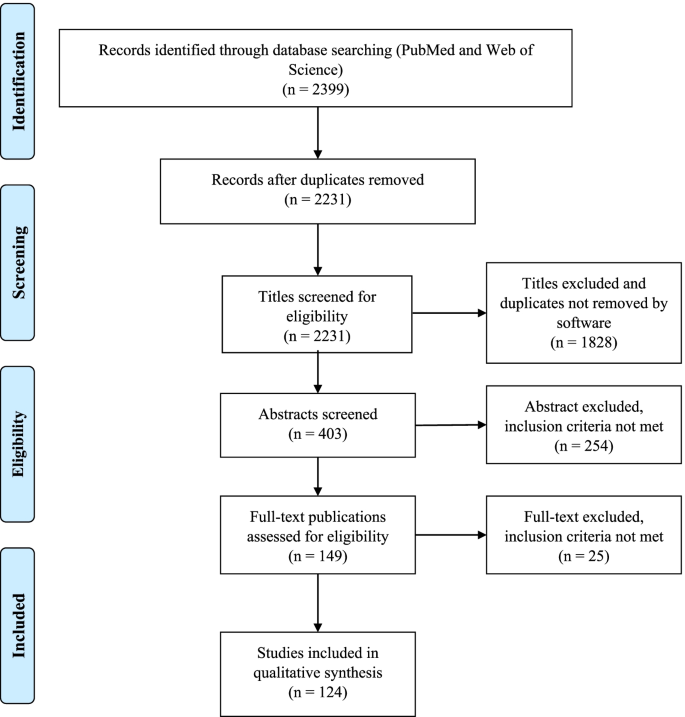

Problem-based learning (PBL) is a pedagogical approach that shifts the role of the teacher to the student (student-centered) and is based on self-directed learning. Although PBL has been adopted in undergraduate and postgraduate medical education, the effectiveness of the method is still under discussion. The author’s purpose was to appraise available international evidence concerning to the effectiveness and usefulness of PBL methodology in undergraduate medical teaching programs.

The authors applied the Arksey and O’Malley framework to undertake a scoping review. The search was carried out in February 2021 in PubMed and Web of Science including all publications in English and Spanish with no limits on publication date, study design or country of origin.