Top 18 Machinist Resume Objective Examples

Updated July 8, 2023 13 min read

A resume objective for a machinist position is a statement that explains your qualifications and career goals. It should be concise, clearly outlining why you are the best candidate for the job. When writing a resume objective, focus on showcasing your experience and skills in relation to the specific role. For example, you might write, “Experienced machinist with 10+ years of experience seeking to use my expertise to ensure accuracy and precision in all projects at ABC Company.” Additionally, it can be helpful to mention any certifications or specialized training you have received related to machining. For instance, “Highly skilled machinist who holds advanced certifications in CNC programming and CAD/CAM software.” By including this information in your resume objective, you can demonstrate how your qualifications make you an ideal fit for the job.

or download as PDF

Top 18 Machinist Resume Objective Samples

- To obtain a Machinist position utilizing my expertise in machining and fabrication to contribute to the success of the organization.

- To secure a Machinist role that will enable me to utilize my skills in precision machining and problem solving.

- Seeking a Machinist position at an established company where I can utilize my experience in setting up, operating, and troubleshooting CNC machines.

- To find employment as a Machinist where I can apply my extensive knowledge of machine shop operations and quality control processes.

- To work as a Machinist for a company that values hard work, dedication, and teamwork.

- Looking for an opportunity to join an organization as a Machinist where I can use my technical skills and knowledge of industrial machinery.

- Seeking a challenging Machinist position with an organization that offers growth opportunities.

- Seeking employment as a Machinist with the ability to operate manual lathes, mills, grinders, saws, drills, etc., while ensuring accuracy and quality standards are met.

- To acquire the position of Machinist at XYZ Company so that I may utilize my skills in precision machining and problem-solving abilities to benefit the organization’s growth.

- Aiming to work as a Machinist at ABC Company where I can use my experience in operating CNC machines and performing maintenance activities on them.

- Applying for the role of Machinist with ABC Company where I can make use of my experience in reading blueprints, setting up tools & fixtures, and performing quality checks on finished products.

- Pursuing an opportunity as a skilled Machinist with XYZ Corporation leveraging 5+ years of experience in operating various types of machine tools safely and efficiently.

- Looking for an entry-level position as a machinist with ABC Company where I can gain hands-on experience while contributing to the team’s success through hard work and dedication.

- Seeking employment as a qualified machinist at XYZ Corporation offering excellent problem-solving skills combined with exceptional mechanical aptitude & attention to detail.

- Aiming for an opportunity to join ABC Company as a skilled machinist utilizing 5+ years of experience in using various hand tools & measuring instruments accurately & precisely.

- Looking for the chance to join XYZ Corporation as an experienced machinist bringing strong knowledge of machine shop operations along with excellent troubleshooting abilities.

- Applying for the role of Machinist at ABC Company leveraging extensive experience working on CNC machines along with strong math & communication skills .

- Searching for an opportunity to work as a highly motivated machinist at XYZ Corporation offering advanced technical knowledge combined with excellent organizational skills & attention to detail

How to Write a Machinist Resume Objective

A machinist resume objective is an important component of a resume for any machinist position. It should clearly communicate the candidate’s qualifications and experience, as well as their career goals. A strong resume objective can help to set a candidate apart from other job seekers and increase their chances of getting called in for an interview.

When writing a machinist resume objective, it’s important to think carefully about what you want to communicate to potential employers. Begin by highlighting your skills and experience that are most relevant to the job you are applying for. For example, if you have experience using CNC machines, be sure to mention this in your objective statement. Additionally, include any certifications or training related to machining that you may have received.

In addition to listing your qualifications, it’s also important to include information about your career goals in your machinist resume objective. Explain what type of position you are looking for and how this position fits into your overall long-term career plans. Doing so will demonstrate that you understand the industry and are actively pursuing a successful future in it.

Finally, make sure your machinist resume objective is concise and professional. Focus on the most important points and don’t go into excessive detail or include any irrelevant information. Keep it short and straightforward while still conveying all the necessary information about yourself as a candidate.

By following these tips when crafting a machinist resume objective, you can create an effective statement that will help you stand out from other applicants and potentially get noticed by employers.

Related : What does a Machinist do?

Key Skills to Highlight in Your Machinist Resume Objective

In the competitive field of machining, your resume objective is a crucial platform to showcase your unique skills and qualifications. The 'Key Skills to Highlight in Your Machinist Resume Objective' section will guide you on how to effectively present your abilities to potential employers. This segment focuses on the essential capabilities that hiring managers often look for in a machinist, including technical acumen, attention to detail, problem-solving skills, and more. By highlighting these key skills in your resume objective, you can set yourself apart from other candidates and increase your chances of landing the job.

1. Blueprint interpretation

A machinist needs the skill of blueprint interpretation as it is crucial in understanding and executing the design and construction of various mechanical parts or tools. This skill is necessary to ensure precision, quality, and adherence to specifications in the manufacturing process. Including this skill in a resume objective demonstrates an applicant's ability to comprehend complex technical diagrams, which is essential for performing tasks accurately and efficiently in a machining role.

2. Precision measuring

A machinist needs the skill of precision measuring because they work with complex machinery and parts that require exact measurements. Any error, no matter how small, can lead to faulty products or equipment failure. Therefore, showcasing this skill in a resume objective demonstrates attention to detail and accuracy, which are crucial for success in this role.

3. CNC programming

CNC programming is a critical skill for a machinist because it involves the ability to program and operate computer numerical control machines, which are used to cut, shape and finish materials in manufacturing. This skill demonstrates an understanding of complex machinery operation, precision, and attention to detail. It also shows the ability to learn and adapt to new technologies, which is essential in a constantly evolving field like manufacturing. Including this skill in a resume objective can highlight the candidate's technical proficiency and commitment to producing high-quality work.

4. Lathe operation

Lathe operation is a crucial skill for a machinist as it involves the use of a key machine in the manufacturing process. This skill demonstrates the ability to shape, cut, drill and form materials accurately, which is essential in creating quality products. Including this skill in a resume objective shows potential employers that the candidate has hands-on experience with important machinery and possesses technical knowledge required for the job.

5. Milling machine expertise

A machinist's job often involves operating various machines to produce precision parts. Milling machine expertise is a crucial skill for this role as it demonstrates the candidate's ability to handle and operate milling machines proficiently. This skill is needed in a resume objective to show potential employers that the candidate has specific knowledge and experience in operating such machinery, which is essential for producing high-quality work in this profession. It also indicates that the candidate can maintain safety standards while working with potentially dangerous equipment.

6. Grinding techniques

A machinist needs to have a strong understanding of grinding techniques as it is a fundamental part of the job. This skill is needed for a resume objective to showcase the candidate's ability to shape and finish parts to precise dimensions, which is essential in creating functional and high-quality products. It also demonstrates their knowledge in operating various grinding machines and tools, ensuring efficiency and safety in the workplace.

7. Metal fabrication

A machinist often works with various types of metals to create parts and tools. Metal fabrication skill is essential as it involves cutting, bending, and assembling processes which are crucial in the production process. This skill demonstrates a candidate's ability to accurately measure, cut, and shape metal materials, ensuring high-quality output. It also shows their familiarity with safety procedures and operation of machinery involved in metalwork. Including this on a resume objective would highlight the candidate's technical capability and precision, making them an ideal fit for the role.

8. Tool maintenance

A machinist's job involves operating and maintaining a variety of machines to produce precision parts and instruments. Therefore, tool maintenance is a crucial skill as it ensures that the machinery is always in good working condition, reducing downtime and increasing productivity. Including this skill in a resume objective demonstrates the candidate's ability to perform routine checks, troubleshoot issues, and carry out necessary repairs or replacements, contributing to efficient operations. It also showcases their technical knowledge, attention to detail, and commitment to quality control.

9. Quality control inspection

A machinist is responsible for creating and maintaining various types of machinery, tools, and parts. Quality control inspection is a crucial skill for this role as it involves checking the quality of the products or components produced to ensure they meet specific standards and specifications. This skill is needed in a resume objective to demonstrate the candidate's ability to maintain high production standards, reduce errors, and ensure safety and functionality of the machines or parts produced. It also shows their attention to detail, precision, and commitment to producing high-quality work.

10. CAD/CAM proficiency

A machinist needs CAD/CAM proficiency because it is essential for creating and interpreting the digital designs used in modern manufacturing processes. This skill allows a machinist to accurately produce or modify parts according to precise specifications, improving efficiency and quality of work. Including this skill in a resume objective demonstrates the candidate's ability to utilize advanced technology in machining tasks, which can be a key requirement for many employers in the industry.

In conclusion, your machinist resume objective should effectively highlight your key skills to show potential employers that you are the ideal candidate for the job. These skills should align with the job requirements and demonstrate your ability to perform tasks efficiently and accurately. Remember, your objective is the first thing employers read, so make it compelling by focusing on what makes you unique as a machinist. A well-crafted objective can significantly increase your chances of landing an interview and ultimately securing the position.

Related : Machinist Skills: Definition and Examples

Common Mistakes When Writing a Machinist Resume Objective

A machinist resume objective is an important part of the resume as it helps to illustrate your career goals and objectives. It is used to explain why you are a good fit for the position and what makes you stand out from other applicants. While writing a machinist resume objective, there are several common mistakes that should be avoided.

The first mistake is failing to tailor the objective to the specific job you are applying for. Many people make the mistake of using a generic objective statement which does not address what makes them uniquely qualified for the position. It is important to research the job description and tailor your objective to match its requirements. This will help show employers that you understand what they are looking for in a candidate and how you can meet their needs.

Another mistake is being too vague or general in your objective statement. Instead of simply stating that you have experience in machine operations, provide details such as specific types of machines operated or accomplishments achieved while working with those machines. You should also include any certifications or specialized training related to machining that you have obtained, as this will demonstrate your commitment to staying up-to-date on industry trends and technologies.

Finally, another common mistake when writing a machinist resume objective is including irrelevant information that has nothing to do with the job at hand. Do not include personal interests, hobbies, or skills unrelated to machining as they can distract from your qualifications as an applicant. Stick strictly to information relevant to the job opening and avoid any unnecessary distractions or details which may detract from your professional capabilities.

By avoiding these common mistakes when writing a machinist resume objective, you can create an effective summary of your qualifications which will help demonstrate why you are the ideal candidate for the position. Good luck!

Related : Machinist Resume Examples

A right resume objective for a machinist would focus on the specific skills and experience that make the applicant an ideal candidate, while a wrong resume objective would be generic and not tailored to any particular job or situation.

Editorial staff

Brenna Goyette

Brenna is a certified professional resume writer, career expert, and the content manager of the ResumeCat team. She has a background in corporate recruiting and human resources and has been writing resumes for over 10 years. Brenna has experience in recruiting for tech, finance, and marketing roles and has a passion for helping people find their dream jobs. She creates expert resources to help job seekers write the best resumes and cover letters, land the job, and succeed in the workplace.

Similar articles

- Top 18 Manual Machinist Resume Objective Examples

- Top 17 Lathe Machinist Resume Objective Examples

- Top 17 CNC Machinist Resume Objective Examples

- Top 16 CNC Lathe Machinist Resume Objective Examples

- Tesla CNC Machinist Resume Examples

- Top 10 Machinist Certifications

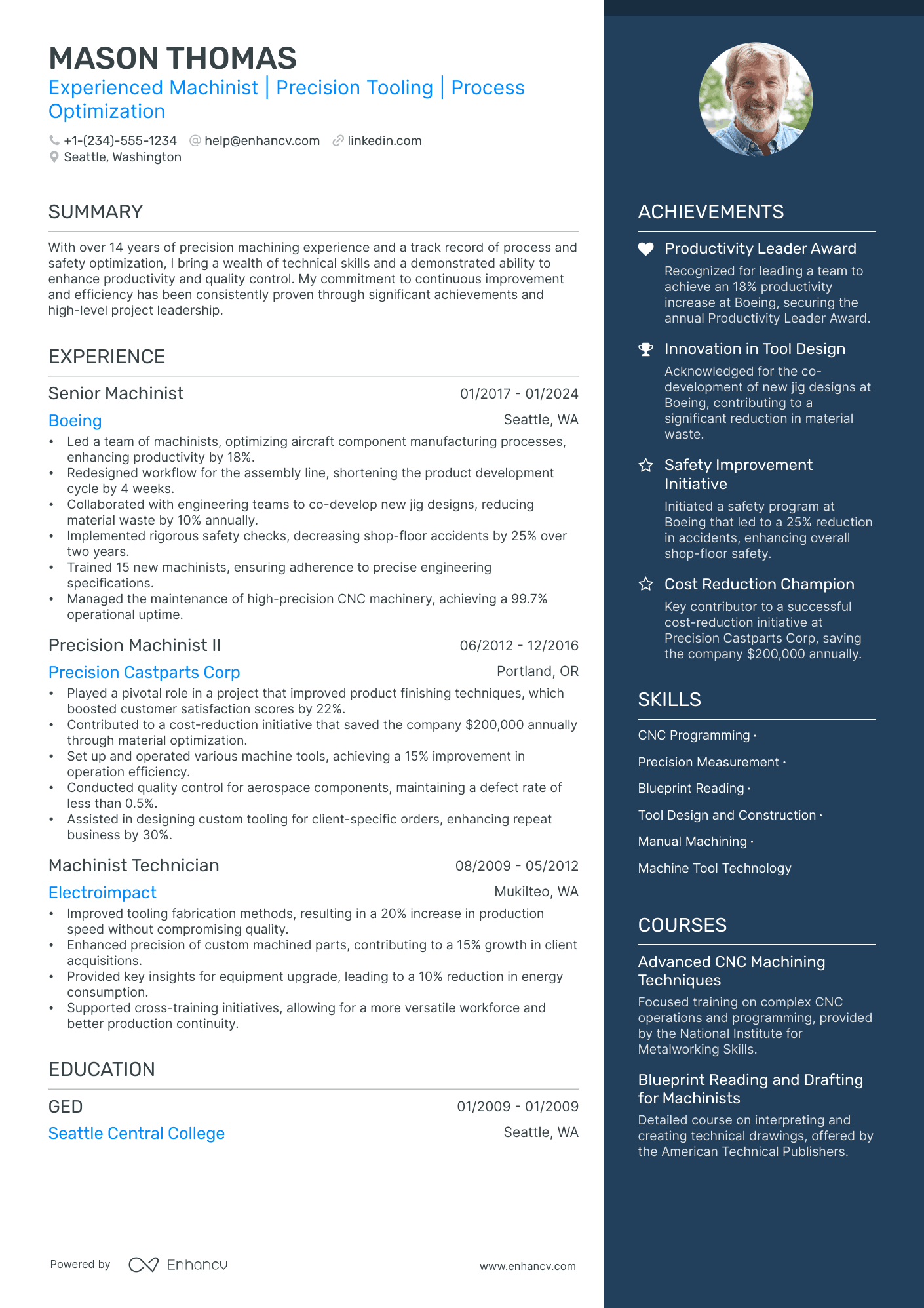

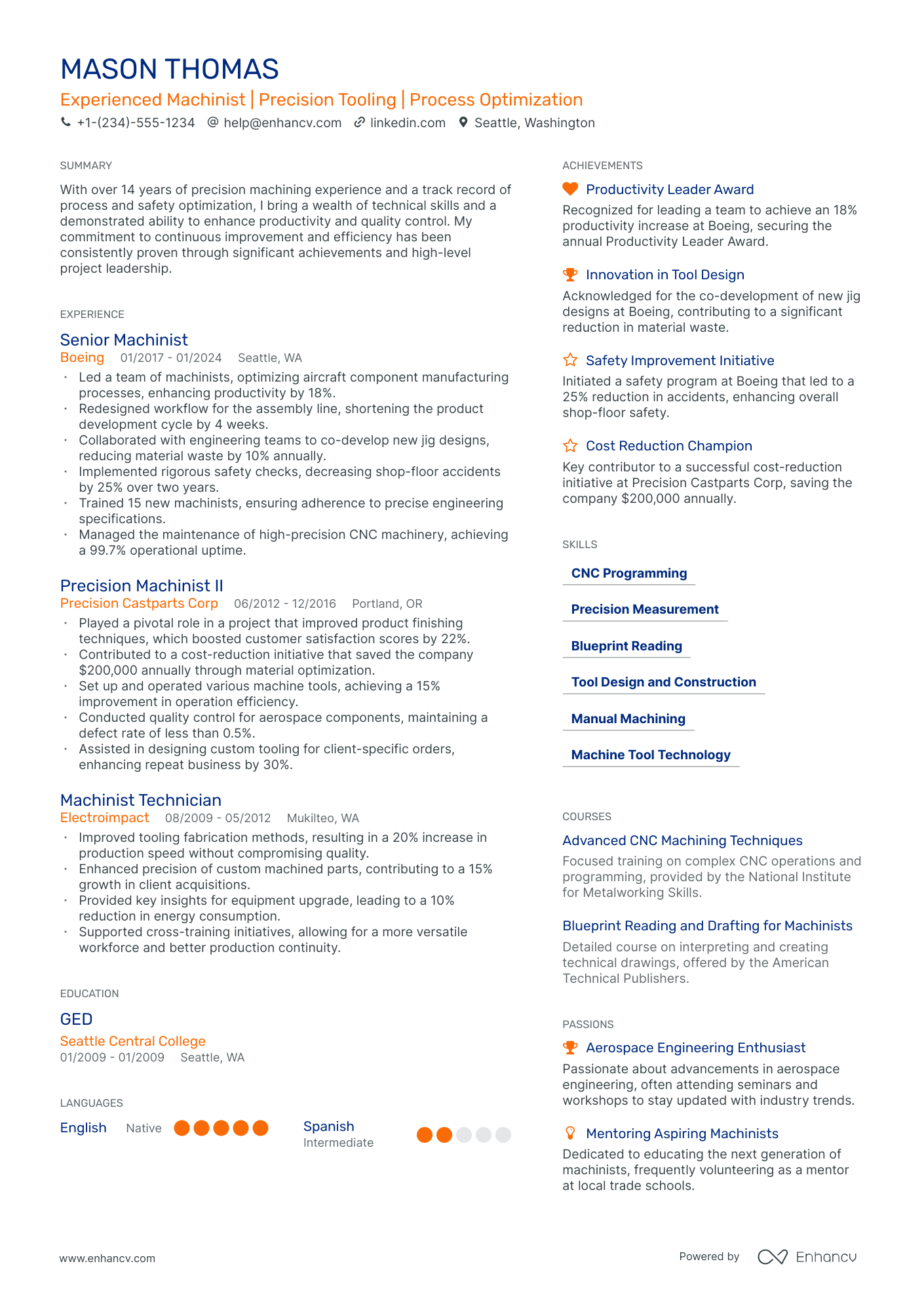

- • Led a team of machinists, optimizing aircraft component manufacturing processes, enhancing productivity by 18%.

- • Redesigned workflow for the assembly line, shortening the product development cycle by 4 weeks.

- • Collaborated with engineering teams to co-develop new jig designs, reducing material waste by 10% annually.

- • Implemented rigorous safety checks, decreasing shop-floor accidents by 25% over two years.

- • Trained 15 new machinists, ensuring adherence to precise engineering specifications.

- • Managed the maintenance of high-precision CNC machinery, achieving a 99.7% operational uptime.

- • Played a pivotal role in a project that improved product finishing techniques, which boosted customer satisfaction scores by 22%.

- • Contributed to a cost-reduction initiative that saved the company $200,000 annually through material optimization.

- • Set up and operated various machine tools, achieving a 15% improvement in operation efficiency.

- • Conducted quality control for aerospace components, maintaining a defect rate of less than 0.5%.

- • Assisted in designing custom tooling for client-specific orders, enhancing repeat business by 30%.

- • Improved tooling fabrication methods, resulting in a 20% increase in production speed without compromising quality.

- • Enhanced precision of custom machined parts, contributing to a 15% growth in client acquisitions.

- • Provided key insights for equipment upgrade, leading to a 10% reduction in energy consumption.

- • Supported cross-training initiatives, allowing for a more versatile workforce and better production continuity.

5 Machinist Resume Examples & Guide for 2024

A machinist must showcase their technical proficiency on their resume. Demonstrate your expertise with machinery and tools through specific experiences or certifications. Include examples of your problem-solving skills. Your ability to troubleshoot and maintain equipment is crucial to highlight.

All resume examples in this guide

Traditional

Resume Guide

Resume Format Tips

Resume Experience

Skills on Resume

Education & Certifications

Resume Summary Tips

Additional Resume Sections

Key Takeaways

As a machinist, one common resume challenge you might encounter is effectively showcasing your technical skills and precision workmanship to potential employers who may not be familiar with the specific machinery you've operated. Our guide can provide you with industry-specific tips to translate your hands-on experience into clear, impactful language that resonates with hiring managers, ensuring your expertise is both understood and valued.

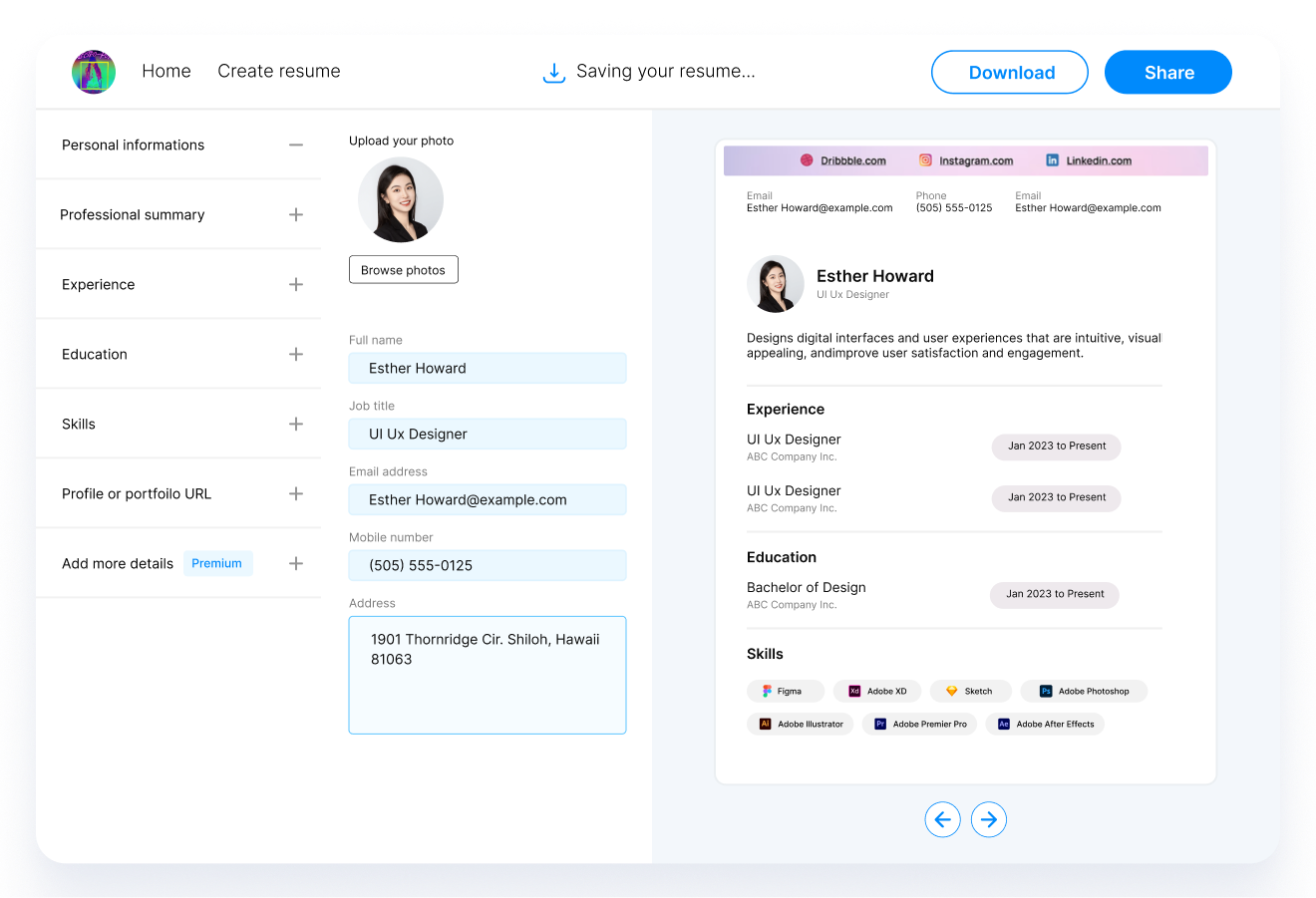

- The most straightforward and effective resume format, ensuring your machinist resume stands out among numerous candidate profiles;

- The significance of the top one-third of your resume, including the header, summary or objective, and skills section, and its impact on recruiters;

- Frameworks and structures used by real machinist professionals, offering insights on how to enhance your resume with industry-specific expertise;

- A variety of machinist resume sections that bolster your profile, showcasing your comprehensive capabilities and distinctiveness.

Gaining insights from the best has never been easier. Explore more machinist resume examples below:

- Welder Resume Example

- Field Manager Resume Example

- Production Technician Resume Example

- Packaging Manager Resume Example

- Automotive Technician Resume Example

- Plant Manager Resume Example

- Carpenter Resume Example

- Distributor Resume Example

- Factory Worker Resume Example

- Export Manager Resume Example

Machinist resume format made simple

You don't need to go over the top when it comes to creativity in your Machinist resume format .

What recruiters care about more is the legibility of your Machinist resume, alongside the relevancy of your application to the role.

That's why we're presenting you with four simple steps that could help your professional presentation check all the right boxes:

- The reverse-chronological resume format is the one for you, if you happen to have plenty of relevant (and recent) professional experience you'd like to showcase. This format follows a pretty succinct logic and puts the focus on your experience.

- Keep your header simple with your contact details; a headline that details the role you're applying for or your current job; and a link to your portfolio.

- Ensure your resume reaches an up-to-two-page limit, only if you happen to be applying for a more senior role or you have over a decade of relevant experience.

- Save your Machinist resume as a PDF to retain its structure and presentation.

Upload & Check Your Resume

Drop your resume here or choose a file . PDF & DOCX only. Max 2MB file size.

If the certificate you've obtained is especially vital for the industry or company, include it as part of your name within the resume headline.

The five (plus) definite sections your resume for a machinist job should include are:

- Header with your headline, contact details, and/or a preview of your work

- Summary (or objective) to pinpoint how your success aligns with the role

- Experience with bullets of your most relevant achievements in the field

- Skills to integrate vital job requirements (both technical and personal)

- Your further dedication to the field, showcased via relevant higher education and/or certifications

What recruiters want to see on your resume:

- Demonstrated ability to read and interpret mechanical documents and drawings

- Proficient in using a wide range of machinist tools and equipment, including CNC machines

- Experience with precision measuring instruments and electronic testing devices

- Knowledge of the properties of metal and other material

- Strong mathematical skills and understanding of machining procedures

Defining your professional expertise in your machinist resume work experience section

The work experience section, often the most detailed part of your resume , is where you discuss your past roles and achievements. To effectively list your experience, consider these four key tips:

- Align your expertise with the job requirements. It's vital to integrate keywords matching the job criteria to pass initial assessments;

- Show, don’t just tell. Quantify your responsibilities by stating your actual achievements in previous roles;

- Include measurable metrics. For instance, how did your performance impact the annual ROI?

- Highlight crucial industry skills. Mention both technological knowledge and interpersonal skills in this section.

These guidelines will help you craft an impressive machinist resume work experience section that is bound to catch recruiters' attention.

- Led a team of machinists in the manufacture of aerospace components, improving product quality by 15% over 2 years through meticulous process optimization.

- Developed innovative jigs and fixtures to expedite the machining process, which increased overall production speed by 25%.

- Designed and implemented a CNC program that reduced waste by 10% and improved material utilization, significantly cutting operational costs.

- Managed the fabrication of custom automotive parts, receiving a 95% customer satisfaction rating for precision and delivery time.

- Introduced a regular maintenance schedule for machining equipment, reducing downtime by 30% and extending machine lifespan.

- Collaborated with engineering teams to prototype parts for new car models, ensuring a 100% fit rate on initial installations.

- Enhanced the accuracy of machined components by performing detailed quality control, achieving a defect rate of less than 0.5%.

- Streamlined the production process by integrating Lean manufacturing principles, leading to a 20% increase in efficiency.

- Conducted training sessions on advanced machining techniques for junior machinists, raising team skills and productivity levels significantly.

- Operated multi-axis CNC machines to produce precision medical devices, while rigorously adhering to FDA guidelines for equipment and process validation.

- Implemented a tooling inventory management system that minimized production stoppages and contributed to a 10% increase in output.

- Collaborated with R&D to enhance product designs for manufacturability, shortening the prototype cycle by two weeks.

- Custom fabricated intricate components for experimental physics research, which required tolerances of up to +/- .0001 inches.

- Played a critical role in supporting the experimental team by providing rapid turnaround on complex, non-standard parts.

- Mastered the use of exotic materials such as Inconel and Titanium to meet highly specific research equipment needs.

- Established and oversaw a continuous improvement program for machining processes that resulted in a sustainable 15% increase in throughput.

- Successfully managed a cross-training initiative to ensure all machinists were proficient in both conventional and CNC machining operations.

- Won 'Best Innovation Award' for designing a proprietary part holding system that reduced setup times by an average of 20 minutes per operation.

- Directed operations within a high-volume machine shop, producing critical engine components with a zero-failure rate over the tenure.

- Implemented an advanced tracking system for project milestones, which improved on-time delivery by 40% for complex orders.

- Fostered a culture of safety and accountability, resulting in a record-breaking 500 consecutive days without a workplace accident.

- Expertly operated and maintained a fleet of high-precision Swiss-style lathes, contributing to a 12% increase in annual production volume.

- Key team member in the redesign of workflow layout, boosting shop efficiency by 35% by minimizing material handling and setup times.

- Took charge of apprenticeship programs, mentoring and training apprentices to become skilled CNC machinists, and reducing skill gaps within the workforce.

Quantifying impact on your resume

- Include the number of complex components you have precision-machined to showcase your technical ability.

- Mention specific tolerances you've achieved in machining parts to demonstrate your attention to detail.

- Detail the percentage of scrap rate reduction achieved through process optimization to highlight efficiency improvements.

- Quantify the amount of time saved on projects by implementing new machining techniques to show your innovation.

- List the volume of materials you have experience with to illustrate your industry versatility.

- State the number of CNC programs you've written or modified to emphasize your programming skills.

- Document any cost savings realized through material selection or process changes to underscore your cost-effectiveness.

- Report the number of successful project completions to reflect your reliability and project management abilities.

Action verbs for your machinist resume

No relevant experience - what to feature instead

Suppose you're new to the job market or considering a switch in industry or niche. In such cases, it's common to have limited standard professional experience . However, this isn't a cause for concern. You can still craft an impressive machinist resume by emphasizing other sections, showing why you're a great fit for the role:

- Emphasize your educational background and extracurricular activities to demonstrate your industry knowledge;

- Replace the typical experience section with internships or temporary jobs where you've gained relevant skills and expertise;

- Highlight your unique skill set, encompassing both technological and personal abilities;

- Showcase transferable skills acquired throughout your life and work experiences so far.

Recommended reads:

- Should I Put In An Incomplete Degree On A Resume?

- When You Should (And Not) Add Dean's List On Your Resume

If you happen to have plenty of certificates, select the ones that are most applicable and sought-after across the industry. Organize them by relevance to the role you're applying for.

Bringing your machinist hard skills and soft skills to the forefront of recruiters' attention

Hard skills are used to define the technological (and software) capacities you have in the industry. Technical skills are easily defined via your certification and expertise.

Soft skills have more to do with your at-work personality and how you prosper within new environments. People skills can be obtained thanks to your whole life experience and are thus a bit more difficult to define.

Why do recruiters care about both types of skills?

Hard skills have more to do with job alignment and the time your new potential employers would have to invest in training you.

Soft skills hint at how well you'd adapt to your new environment, company culture, and task organization.

Fine-tune your resume to reflect on your skills capacities and talents:

- Avoid listing basic requirements (e.g. "Excel"), instead substitute with the specifics of the technology (e.g. "Excel Macros").

- Feature your workplace values and ethics as soft skills to hint at what matters most to you in a new environment.

- Build a separate skills section for your language capabilities, only if it makes sense to the role you're applying for.

- The best way to balance machinist hard and soft skills is by building a strengths or achievements section, where you define your outcomes via both types of skills.

There are plenty of skills that could make the cut on your resume.

That's why we've compiled for you some of the most wanted skills by recruiters, so make sure to include the technologies and soft skills that make the most sense to you (and the company you're applying for):

Top skills for your machinist resume:

Blueprint reading

Manual dexterity

CNC (Computer Numerical Control) operation

Precision measurement

Machine setup and maintenance

Metalworking

Lathe operation

Tool sharpening

Attention to detail

Problem-solving

Time management

Critical thinking

Adaptability

Communication skills

Continuous learning

Safety consciousness

Listing your relevant degrees or certificates on your machinist resume is a win-win situation. Not only does it hint at your technical capabilities in the industry, but an array of soft skills, like perseverance, adaptability, and motivation.

The importance of your certifications and education on your machinist resume

Pay attention to the resume education section . It can offer clues about your skills and experiences that align with the job.

- List only tertiary education details, including the institution and dates.

- Mention your expected graduation date if you're currently studying.

- Exclude degrees unrelated to the job or field.

- Describe your education if it allows you to highlight your achievements further.

Your professional qualifications: certificates and education play a crucial role in your machinist application. They showcase your dedication to gaining the best expertise and know-how in the field. Include any diplomas and certificates that are:

- Listed within the job requirements or could make your application stand out

- Niche to your industry and require plenty of effort to obtain

- Helping you prepare for professional growth with forward-facing know-how

- Relevant to the machinist job - make sure to include the name of the certificate, institution you've obtained it at, and dates

Both your certificates and education section need to add further value to your application. That's why we've dedicated this next list just for you - check out some of the most popular machinist certificates to include on your resume:

The top 5 certifications for your machinist resume:

- National Institute for Metalworking Skills Certification (NIMS)

- Precision Machining Technology Certificate (PMTC) - Various Trade Schools

- Computer Numerical Control (CNC) Machinist Certificate - Various Trade Schools

- Mastercam Certification Program (MCP) - CNC Software, Inc.

- Certified Manufacturing Engineer (CMfgE) - Society of Manufacturing Engineers (SME)

- How to List a Major & Minor on Your Resume (with Examples)

The machinist resume summary or objective: integrating keywords, achievements, and more

Deciding whether to include a resume summary or an objective in your machinist resume is crucial. Both serve as key introductory elements at the top of your resume, encapsulating your profile in up to five sentences and incorporating relevant keywords from the job advert.

Here are the key differences between the two:

- The resume summary focuses on aligning your achievements and experience with the job requirements. It provides recruiters with a snapshot of your expertise , helping you stand out as an ideal candidate for the role.

- The resume objective, on the other hand, centers on your career goals and aspirations , detailing how the role aligns with your career progression. It's particularly suitable for candidates with less professional experience or those new to the job market.

Below are examples demonstrating best practices in utilizing the resume summary and/or objective to make a strong first impression with your machinist resume.

Resume summaries for a machinist job

- With over a decade of precision machining experience, adept in operating CNC machinery and complex lathe equipment, I have consistently delivered high-quality components within the aerospace industry. My crowning achievement includes reducing material waste by 15% through enhanced machining strategies at Globetech Aerospace.

- As an experienced machinist with 7 years of experience in the automotive manufacturing sector, I specialize in programming, setting up, and operating CNC machines to produce high-tolerance parts. Recently, I led a team project that achieved a 20% increase in production efficiency at Piston Automotive Solutions.

- Transitioning from a career in IT with robust problem-solving and analytical skills, I am eager to apply a methodical and detail-oriented approach to the field of precision machining. With comprehensive training in CAD/CAM software and a strong mechanical aptitude, I am well-prepared to contribute effectively to high-stakes projects.

- Seeking to bring a fresh perspective to machining from a background in material science, my unique understanding of metallurgical properties can enhance the development and fabrication of metal parts. I have hands-on experience with 3D printing and am proficient in SolidWorks, ready to apply these skills to traditional machinist tasks.

- Aspiring machinist with a strong foundation in mechanical engineering principles, I am enthusiastic about beginning my professional journey by mastering CNC programming and operations. My ultimate objective is to specialize in the creation of medical devices and to become a leading expert in the manufacturing of lifesaving technology.

- Eager to launch a career in machining with no prior experience but equipped with a fast learning curve and a commitment to quality craftsmanship. My objective is to acquire hands-on skills in operating advanced machinery and to ultimately contribute to groundbreaking innovations in the field of renewable energy components.

Extra sections to include in your machinist resume

What should you do if you happen to have some space left on your resume, and want to highlight other aspects of your profile that you deem are relevant to the role? Add to your machinist resume some of these personal and professional sections:

- Passions/Interests - to detail how you spend both your personal and professional time, invested in various hobbies;

- Awards - to present those niche accolades that make your experience unique;

- Publications - an excellent choice for professionals, who have just graduated from university or are used to a more academic setting;

- Volunteering - your footprint within your local (or national/international) community.

Key takeaways

- The format and layout of your machinist resume should reflect on both your career and what matters most to the job you're applying for;

- Use the resume summary and objective to hint at your most prominent accomplishments;

- Always be specific about your experience and consider what value each bullet you curate adds to your machinist application;

- Consider how your academic background and technical capabilities could further showcase your alignment to the role;

- Your soft skills should contribute to your overall machinist profile - aligning your personality with skills and results.

Looking to build your own Machinist resume?

- Resume Examples

Is It OK To Send A Resume Without A Cover Letter

How to become a nurse in the us [salary, key skills & job application tips], how to answer the interview question, “why do you want to work here”, why does my resume look different when i upload it, turning the tables: how an informational interview can launch your new career (with 24 bonus informational interview questions you can use), what stands out on a resume.

- Create Resume

- Terms of Service

- Privacy Policy

- Cookie Preferences

- Resume Templates

- AI Resume Builder

- Resume Summary Generator

- Resume Formats

- Resume Checker

- Resume Skills

- How to Write a Resume

- Modern Resume Templates

- Simple Resume Templates

- Cover Letter Builder

- Cover Letter Examples

- Cover Letter Templates

- Cover Letter Formats

- How to Write a Cover Letter

- Resume Guides

- Cover Letter Guides

- Job Interview Guides

- Job Interview Questions

- Career Resources

- Meet our customers

- Career resources

- English (UK)

- French (FR)

- German (DE)

- Spanish (ES)

- Swedish (SE)

© 2024 . All rights reserved.

Made with love by people who care.

- Knowledge Base

- Free Resume Templates

- Resume Builder

- Resume Examples

- Free Resume Review

How to write a machinist resume in 2023?

[ Click here to directly go to the complete Machinist Resume Sample ]

Your Machinist resume is the first official document that a hiring manager reviews, and it sets the first impression on the prospective employer about you.

According to LinkedIn, 6 seconds is the average time spent reading a resume . Therefore, your resume must be neatly formatted that reflect your skills and qualifications that catch the recruiter's attention at first glance.

Confused where to start from? Do not fret. In this guide, we will guide you through the basics of writing a machinist resume for your dream job that will immediately get the hiring manager's attention.

Hook yourself in our 2023 guide to help you create the perfect machinist resume and create one machinist resume for yourself.

In case you want the summary of our machinist resume guide, here it is:

- Suitable keywords should be used to customize your resumes as per the targeted job profile that you are applying for to help you pass the ATS test.

- Providing phone number and professional email id in your resume is a must as it is the only way for the recruiters to get in touch with you if you are shortlisted for the interview.

- Provide an overview of your resume by composing a compelling resume summary/objective to highlight your career achievements.

- Group similar bullet points under a relevant subheading and highlight the important words and phrases to increase the readablility of your machinist resume.

In this guide, we will cover the following topics in detail:

- Why do you need a machinist resume?

- Which machinist resume format is best to make your machinist resume?

- What are the various resume sections that you must include in your machinist resume?

- How to curate a perfect professional experience section to highlight the relevant experience in your machinist resume?

In the meantime, go to the Hiration's Online Resume Builder and let us help you create a perfect machinist resume. In case if you want to make your machinist resume all by yourself, then hook yourself to our guide until the end to help you create the perfect machinist resume all by yourself.

What Is a Machinist Resume And Why Do You Need It?

The machinist resume is a formal document that you, as a job applicant, need to itemize your qualification for a position. Typically, your resume must be accompanied by a customized machinist cover letter as well to express your interest and enthusiasm for the job role.

Use your machinist resume to present detailed information about your relevant experience and skills in as short a space as possible. An ideal length of a resume is one page, or it can extend to a maximum of 2 pages.

A resume helps you sell your skills to the hiring manager by demonstrating your actual value to the employers. If done right can get you the job as well.

According to Jobscan, over 98% of Fortune 500 Companies Use Applicant Tracking Systems (ATS) to filter resumes based on the requirement of the role . Therefore, it is imperative that your machinist resume is ATS friendly, at least to make it to the hiring manager's table.

Turn to our online resume builder to create your machinist resume and a cover letter in compliance with industry norms. With our impressive features and 25+ designs, we can help you make an ATS-friendly machinist resume that draws the attention of the hiring manager.

Meanwhile, if you are a young professional, or do not know how to write a resume, follow Hiration how to write a resume guide to understand the basic principles of writing a professional resume.

Machinist Job Description

Machinist is a highly technical line of work and is responsible for producing and processing parts. Your machinist resume must include your experience in operating different types of machines and other vital information that apply to the job position you are seeking.

Steps To Follow To Beat The Bots

- Step 1: Read and analyze the job description of the position you are seeking

- Step 2: Write your machinist resume job title as mentioned in the job listing

- Step 3: Tailor your skills in your machinist resume to the keywords in the job description

- Step 4: Include the location in your machinist resume as required for the job position

Reading the machinist job descriptions carefully is crucial to curating your machinist resume that is ATS friendly by including relevant keywords in your resume. Pay special attention to job title, job requirements, roles and responsibilities, and location in the job description.

Include all the skills, key achievements, and experience you have held in the past that match with the job description. You must customize your resume to every job position you apply to before sending it to the hiring manager.

Machinist Salary

According to Indeed.com , the average base salary in the United States job market is $21.64 per hour.

According to Salary.com , the average machinist salary in the united states is $44,970.

According to Payscale.com , the average base hourly rate in the united states is $20.01.

What Are The Different Machinist Resume Formats?

Which type of machinist resume format is right for you?

There are three standard resume formats you can choose from while crafting your machinist resume. The resume format you choose must help you make an organized and professional machinist resume.

Your resume format determines your first impression and how the recruiters and the hiring managers view your candidacy. Let's have a look into the three common three types of resume formats:

- Reverse chronological: This is the most classic and most used resume format. A reverse chronological resume lists your work experience in a reverse chronological order, which means your most recent work experience is written first and then works backward.

- Functional: The functional resume format is skill-based. What differentiates functional resume format from reverse chronological resume format is that it focuses more on your skills than your work experience.

- Combination/Hybrid: The hybrid resume format, also known as the combination resume format, is a mix of reverse chronological and functional resumes. This is used to highlight the skills and work experience as desired to detail the career trajectory.

Note: Whether you are a recent graduate or have a years of experience as a machinist, always choose a reverse chronological resume format to make your machinist resume. Choose a functional resume format if you have significant gaps in your work history to focus more on your skills.

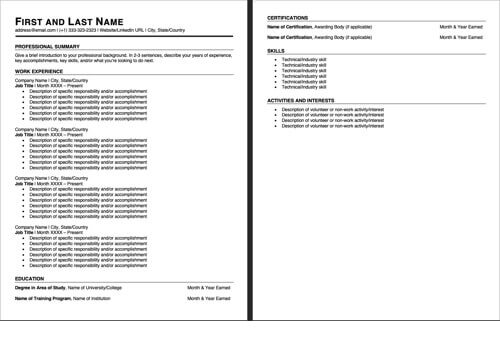

What Are The Resume Sections That You Must Include In Your Machinist Resume?

Here are the key sections of a Machinist resume. Your resume sections must be readable friendly for both human readers and the applicant tracking systems (ATS). You must follow the best practices for these resume sections and ensure that all the information is included in the specific section.

- Personal Information

- Profile Title

- Summary / Objective

- Technical Skills (if any)

- Professional Experience

- Certifications (if any)

- Awards & Recognition (if any)

- Additional Information (if any)

Few writing tips to make an awesome machinist resume before we learn each resume sections in detail:

- Look for keywords in the job descriptions to understand what the employer is looking for in a candidate. Do not waste your time applying for a job position you are not interested in.

- Choose the best resume format for your machinist resume that strikes the perfect balance between your experience and targeted job profile.

- Use a professional font that is easy to read and understand. Using a font size between 10 and 12 points is recommended for your machinist resume.

- Prioritize the essential information first. Include only the information in your machinist resume that is relevant to the job position you are applying for.

- Only include the relevant resume sections and subheadings. Whether you're using a resume template or creating on your own, there are some resume sections you do not need. For example, either you need a resume summary section or a resume objective, but you should not include both.

Follow the Hiration's Resume Key Section guide to get a more clear understanding about the sections of a resume.

Alternatively, you can go to the Hiration's Resume Builder and select from the library of 20+ professional templates and tweak them to create a banquet server resume.

Machinist Resume Sample

- CNC Machinist Training Program | Universal Technical School | Boston, MA | '20

- EPA Amusement Operators Safety Certification | Zippia Institute | Boston, MA | '18

- Received ' Employee of the Year Award ' for outstanding performance and timely completion of assigned tasks

- Conducting product quality inspections while identifying and recommending process improvement suggestions

- Performing mechanical maintenance and repair tasks to enhance equipment operational reliability and functionality by 20%

- Diagnosing & troubleshooting the root cause of malfunction of industrial machines while ensuring 95% precision

- Operating press, drill, saw, and deburring machines to fabricate parts while adjusting machine controls as required

- Implementing equipment maintenance plans through coordination with management, engineers, and materials staff

- Deploying micrometers and other quality assurance tools to assure that the parts are within product specifications

- Rendering assistance in analyzing and interpreting blueprints as part of verifying dimensions & alignment of finished products

- Delivered assistance in cleaning the machine between cycles to streamline the production process and foster higher workplace morale

- Assisted engineers and technicians in mission-critical projects while ensuring compliance with policies and procedures

- Deployed precision measuring instrument to verify dimensions of machine parts within the stipulated time frame

- Maintained machine setup information documents including CNC software , machine programming, and program updates

- CGPA: 3.8/4.0

- Course Modules:

- Precision Measurement | Blueprint Reading | Lathe and Milling Operation | Manufacturing Math | Quality Control

What Is A Header In A Machinist Resume?

As the name suggests, a resume header is the heading of your machinist resume and will be the 1st thing to be noticed by a hiring manager. Ensure that you include all the vital information in the header for what it is meant to be.

Let's understand how should you design your machinist resume header:

- Avoid the age-old practice of writing a CV or Resume as your resume header. This practice takes away your chance of customizing the resume from the beginning. Avoid it at all costs.

- Instead, write your full name as the resume header. It will help the recruiter recognize your resume, among other resumes.

- The resume header font must be written in a size range of 16-20 points.

- Always leave a single space between the first and the last name.

- For middle name , only add the initial of the middle name in the resume header.

For example: If your name is Kenny Zakir Philippines, you should write in your resume, Kenny Z. Philippines.

Below is an example of a machinist resume header curated in our online resume builder

How Should You Write Your Personal Information Section In A Machinist Resume?

The personal information section in your machinist resume includes some of your essential details, such as contact number, email address, location, etc.

You should proofread multiple times to avoid the chances of overlook or misspelling your details in your machinist resume, as this may cost you the job.

Let's have a look into the necessary personal details required for your machinist resume:

- Your mobile number that works 24/7

- Professional email address

Contact Number

Provide a contact number and make sure that it is active.

Write your contact number in this format: Add the country code without the brackets, add a space, then the 5 digits of your number, then another space, and then the remaining 5 digits.

Ensure that the number you put in your machinist resume is functional. Some people tend to miss out on many opportunities because the contact number provided in the resume was unreachable. Make sure that it doesn't happen to you, so be extra careful.

Email Address

An official email address holds as much importance as your contact number. It is also one of the ways for the recruiter to reach out to you.

Ensure that you do not provide any email address that is not professional as it can set a wrong impression about you on the hiring manager.

Below are a few examples of how your email address should look like in your machinist resume:

Hiration Pro Tip: Avoid using spammy-looking email id such as james.harry.9323#@gmail.com

The location on your resume does not refer to your full address, street name, or locality name on a resume. Providing your complete street address is unnecessary as it is not important for the hiring manager while reviewing your candidacy for the job position.

When applying for a job in your current city or state, simply mention your location in the city, state format.

But, while applying for a job abroad, you have to enter your location in the city, country format.

Note: Your personal information doesn't include your physical characteristics, beliefs, or creed, such as your gender, religion, sex, etc. This information is irrelevant to the hiring manager.

You can add the link to your LinkedIn/GitHub Profile in your resume as well. Add your LinkedIn profile only when it is optimized and professional or else you can avoid it.

Thankfully, in the Hiration Resume Builder , we have implemented all these formatting rules required to create a professional resume. So, if you are using Hiraiton Resume Builder, you can make your machinist resume worry-free.

Take a look at the personal information snapshot to help you compose your machinist resume:

How To Write Your Profile Title In A Machinist Resume?

The profile title on your machinist resume is an essential part of the resume, like any other section in your resume.

It helps the hiring manager to understand your expertise level and experience.

A profile title should ideally include three things:

- Your current designation.

- Your functional industry.

- Your seniority level.

Here are some few tips to help you frame a perfect profile title for your machinist resume:

- Ensure that the profile title is the second-largest text in your resume after the resume header.

- Use the ideal 14-16 font size to frame the machinist resume profile title.

Note: Make sure that your profile title is relevant to the job you're targeting and, in a way, bolstering your professional experience.

In the meantime, use Hiration Resume Review service to get your existing banquet server resume reviewed for creating a professional resume.

Below is a snapshot of machinist resume profile title to help you create an ideal profile title for your machinist resume

How To Create An Impeccable Summary For Machinist Resume?

You must write a resume summary if you have a few years of work experience in your target job profile. If you have work experience as a machinist, you can use the summary space to summarize your work experience and convey your expertise. In this way, you can frame yourself as an ideal candidate for the machinist job.

Below are a few points that should be kept in mind while framing a resume summary-

- Curate a resume summary only if you have 3-4 years of relevant work experience

- The resume summary should not exceed 3-4 lines. If you are a working professional with 10+ years of experience, only then it can be more than that.

- Mention how you utilized your skill-set to achieve results in your previous company.

- Use cause-effect methodology to frame your summary sentences.

- Start your resume summary by mentioning the number of experiences you have.

- Including quantifiable data in the resume summary will give the recruiter a nuanced understanding of your work.

If you want to learn more about resume summary, read our Hiraiton 2023 Resume Summary Guide to create an impeccable resume summary.

Below is a snap of a summary of a machinist resume to help you write an impecccable summary for your resume

When Should You Create An Objective Section In Your Machinist Resume?

Confused, what is a resume objective? Let's discuss when do you need to write a resume objective in your machinist resume.

If you have no experience in the machinist job, you might ask yourself how you should create your resume, and this is where the resume objective comes in. If you have no or minimal experience, you must consider writing a resume objective than a resume summary.

Let's see who can use a resume objective:

- Entry-level working professional

- If you have below 3 years of experience in the targeted job profile

- A person covering up long gaps in the resume

- Someone who is shifting/changing industries

Now that you know who can use a resume objective, you should also know how to use a resume objective

- Keep the resume objective 3-4 sentences long.

- Explain how our skills set and experience can contribute to the growth of the organization.

- Keep the objective section to the point

- Use cause and effect methodology to frame your sentences.

Go through Hiration's 2023 Guide on Resume Objectives to understand how to create a perfect resume objective for banquet server resumes.

How To Write Your Skills In A Machinist Resume?

The skills section of a resume is ideally the best place to highlight and showcase your expertise as a machinist.

You should read the job description carefully and include keywords in your machinist resume skills section to raise the chance of your resume getting parsed by the ATS.

There are different types of skills that you can add in your resume to validate your potential to the recruiters.

Both technical skills and functional skills should be highlighted separately to ensure that your expertise in your professional line is defined accordingly.

You must be wondering how to add all these skills. Well, a lot of it depends on the profile you're targeting.

A machinist profile would require you to possess technical skills that can be used to execute the task that revolves around the profile. While also require you to possess functional skills to manage, organize, monitor, execute, etc.

However, if you have specific skills that aren't required but you think it will enhance your capabilities, you should definitely add them to the list.

Hiration Pro Tip: Do not add skills that you can't substantiate in your professional experience section. Bold all your key skills and separate them with a (•) to better highlight your skills.

For more information, go to Hiration 2023 guide on how to write key skills on a resume and read it.

Check out the ideal example of a skills section to help you create an ATS friendly machinist resume

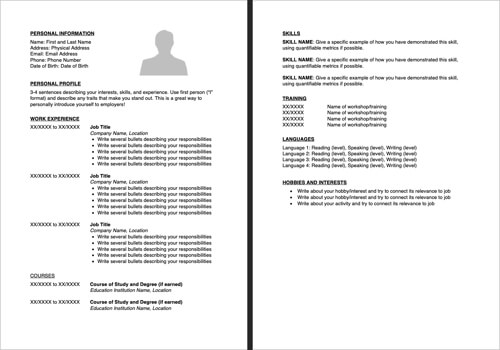

How to Highlight Your Professional Experience In A Machinist Resume?

The professional experience section of your resume is the section you need to capitalize on. The section highlights your skills and your professional key achievements in bullet forms that are highly relevant for your targeted job profile.

The professional experience section must entice the hiring managers to know more about you and create the maximum chance for you to get shortlisted for the interview. You must ensure that you are not putting out any information in the professional experience section that is unnecessary and irrelevant to your targeted profile.

As resume professionals, we have developed a three-way process to create an impeccable professional experience section for a resume with our years of trials and errors.

- Frame one-liner bullet points starting with power verbs to write your accomplishments

- Use Bucketing & Bolding to emphasize key sections and accomplishments

- Use the STAR format to structure the bullet points for maximum impact

Read on to understand how these three points work to create an impressive machinist resume for yourself.

Framing Points

Framing one-liner points makes your resume readable and understandable. Writing your professional experience in a paragraph format makes your resume difficult to read and incomprehensible.

The primary goal of your resume should be to improve readability. The method of framing one-liner points to list your professional experience is the most advisable and accepted way of presenting your professional experience in your resume.

Make it a point to start your bullet points with power verbs. Read our guide on resume action and power verbs to craft an impeccable professional experience for your resume.

Use achievement figures in your bullet points to give an approx idea to the hiring manager of your contribution in your past endeavors.

Bucketing and Bolding

What is bucketing and bolding?

Bucketing is the process of and listing down all the similar points under the relevant sub-heading. Bold important words, phrases, and numbers to highlight your skills and critical contribution in your resume.

When you list your similar points under relevant buckets, it helps to organize your experience and grab the much-needed attention from the recruiter.

Note: Put a maximum of 3-4 similar bullet points under one subheading and do not overbold. Bold only significant words and numbers.

STAR Format

Using the STAR format technique helps you highlight your accomplishments more effectively by creating a cause-effect relation that impacts the recruiter's minds.

The STAR stands for:

- S stands for Situation, as in the situation you have executed the task.

- T stands for Task, the task that was assigned to you.

- A stands for Action, actions you undertook to perform the assigned task.

- R stands for Result, The Results or outcome of your action.

Here is an ideal example of a professional experience section using STAR formatting

Education is a significant factor that decides your relevance and compatibility with the targeted job. Use the reverse chronological format while listing your degrees on the resume.

Keep the below-mentioned points in mind while formulating the education section of your resume-

- Mention the name of your university first.

- Provide the dates in (mm/yy - mm/yy) format for the graduation duration on the right side.

- Mention the location of your university along with a short one-line description of it.

- Mention the course modules and additional accomplishments/ certifications relevant to your targeted job profile.

Note: If you have above 3 years of work experience, you can remove 10th and 12th from your resume.

To get a better understanding of the education section of the resume, read Hiration 2023 guide on How to write education information on a resume .

Check out the education section snapshot to help you highlight your qualification in your machinist resume in the best manner possible

How To Curate Certifications Section In A Machinist Resume?

If you possess any certifications to prove your relevant experience, then do not hesitate to add this section to your machinist resume.

If you own machinist relevant certifications, it can not only increase your chances of getting shortlisted for an interview but also opens up a path for higher-paying jobs.

For all your certifications, follow this format:

Certification | Certifying Authority | Time Period

If you have a highly important certification for the job profile you are looking for, you must include all the course modules and topics you covered under the same in one-liner sub-bullets right below.

Get more details on how to craft a perfect certification section on a resume from Hiration's 2023 Guide on listing certifications on a resume .

This is how you should make a certification section in your machinist resume

How To Write Additional Information In A Machinist Resume?

Addition information is the last section of your resume. You can retain information such as hobbies, languages known, etc.

Listing hobbies relevant to the job and knowing multiple languages throws light on the productive aspect of your personality and gets you extra credits from the hiring managers.

Machinist Cover Letter

A machinist cover letter that goes with a well-framed resume can highly increase the chances of your job application getting shortlisted.

Send a cover letter along with your resume helps you to step up your job search game and help you stand out of the crowd. Consider sending a cover letter even if you are not asked to send one. Do not send a cover letter only when you are specifically requested not to.

Let's understand how should you design your machinist cover letter-

- Your cover letter gives the recruiter a glimpse of your skills and achievements in a more personalized way.

- Write short and crisp paragraphs. Readability is essential.

- Do not exaggerate your achievements or say anything that is not true.

- Frame your cover letter to showcase your interest and enthusiasm for the machinist job.

- Make sure that you create a customized cover letter for every company you apply to.

- Do not commit the mistake of sending a generic cover letter for every company you apply to.

Wondering how to create a machinist cover letter?

No worries!

Simply head to Hiration Cover Letter Builder and get assistance from our experts or simply pick any pre-filled sample and customize according to your needs.

Hiration Resume Review Service

Upload your existing machinist resume on our Online Resume Builder and let the resume-making professionals and experts help you with your resume.

Our experts will review your resume in compliance with the following parameters:

- Content Relevance

- Recruiter Friendliness

- Design Compatibility

- Conversion Scope

- ATS Compliance

- Global Compatibility

- Performance Assessment

- Resume Formatting

- Compliance with industry norms

Make the best use of our Resume Review Service today!

Hiration's Online Resume Builder

The resources listed below comes with Hiration's Online Resume Builder:

- Option to save unlimited resumes

- Intuitive next text suggestion

- Auto bold feature

- 25+ resume designs

- LIVE resume score

- JD-resume matcher

- Full rich-text editor

- Unlimited PDF downloads

- 100+ pre-filled resume templates

- 1-click design change

- A sharable link

- LIVE resume editor

If you want to create a professional Machinist Resume for yourself, Hiration's Resume Builder is here to help. Register yourself, and pick from 25+ highly customizable templates and follow our guidelines to create an impressive Machinist resume for yourself.

Key Takeaways

- Always describe your professional experience in one-liner points and place them under relevant headings so that the recruiters can easily read and comprehend your points.

- Bold words, phrases, or achievements figures in your one-liners to make it easier for the recruiters to identify your achievements and contributions right away.

- State only your accurate profile title to maintain your professional identity.

- If your resume has a space after you have included all the vital details, Include a one-line company description for each of your company including some figures around the number of employees, revenue, etc.

- Refer to the hiring guidelines before giving out your details in a resume as the requirements for every organization and recruiters vary from one another.

Go to Hiration resume builder and create a professional resume for yourself. Additionally, reach out to us at [email protected] and you can get 24/7 professional assistance with all your job & career-related queries.

Share this blog

Subscribe to Free Resume Writing Blog by Hiration

Get the latest posts delivered right to your inbox

Stay up to date! Get all the latest & greatest posts delivered straight to your inbox

Is Your Resume ATS Friendly To Get Shortlisted?

Upload your resume for a free expert review.

Mastering the Art of Machinist Resume Writing: A Comprehensive Guide

In this guide, we delve into the intricacies of writing an exceptional resume for a machinist role in the Manufacturing & Warehousing sector. As machinists play a pivotal role in the manufacturing process, their resumes need to mirror their precision and expertise. This guide will walk you through each step of crafting a resume that not only showcases your skills and experience but also speaks directly to the needs of employers in this dynamic industry.

Crafting the Perfect Machinist Resume: A Real-World Example

Samantha Lopez Machinist Contact: 555-123-4567 | [email protected] LinkedIn: linkedin.com/in/samanthalopez

Detail-oriented and precision-focused Machinist with over 5 years of experience in CNC operation, manual machining, and CAD/CAM programming. Proven track record in improving production efficiency and accuracy in high-volume manufacturing environments. Adept at interpreting blueprints and executing complex machining processes with a commitment to quality and safety.

Professional Experience:

Lead CNC Machinist Advanced Manufacturing Co. Houston, TX | May 2019 -- Present

Supervise a team of 5 machinists, overseeing CNC operations for automotive component production.

Innovated a tooling modification that increased production efficiency by 20%.

Manage machine maintenance, reducing downtime by 15%.

CNC Machinist Precision Parts Inc. , Dallas, TX June 2015 -- April 2019

Operated CNC machines to produce aerospace components, maintaining a 99.8% accuracy rate.

Collaborated in the design of new jigs and fixtures, improving overall production time by 10%.

Conducted regular training sessions for new staff on machine operation and safety protocols.

A.A.S. in Precision Machining Technology Texas State Technical College, Waco, TX Graduated May 2015

CNC Machine Operation

Manual Machining

CAD/CAM Programming

Blueprint Interpretation

Quality Control

Safety Compliance

Team Leadership

Certifications:

Certified CNC Machinist (National Institute for Metalworking Skills)

OSHA Safety Certification

Enhancing Your Resume's Impact: Effective Structure and Layout

When crafting a resume for a machinist position, the structure and layout play a crucial role in showcasing your qualifications effectively. A well-organized resume not only makes it easier for hiring managers to find the information they need but also highlights your professionalism and attention to detail -- key traits for a machinist.

The Anatomy of a Well-Structured Machinist Resume

1. Header: Start with a clean header including your name, job title (Machinist), and contact information. Make sure it's easy to find and read.

2. Summary or Objective: A brief, impactful section that summarizes your experience and skills, tailored to machinist roles. This is your elevator pitch, so make it count.

3. Work Experience: List your previous jobs in reverse chronological order. Focus on achievements and responsibilities that relate directly to machinist duties. Quantify your accomplishments where possible, such as "increased production efficiency by 20%."

4. Education: Include relevant educational background, particularly any machining or engineering-related qualifications. Technical certifications or apprenticeships are also valuable here.

5. Skills: Highlight specific skills that are essential for a machinist, such as CNC operation, precision measurement, and blueprint reading. Tailor this section to match the job description.

6. Additional Sections: Consider adding sections for certifications, awards, or volunteer work, especially if they demonstrate skills or qualities relevant to machining.

Formatting Tips for Clarity and Readability

Consistency: Use the same font and formatting throughout your resume. This includes font size, bullet points, and headings.

Whitespace: Adequate spacing makes your resume more readable. Avoid clutter and use bullet points for lists.

Length: Aim for one page if you have less than 10 years of experience. For more experienced machinists, two pages can be acceptable.

File Format: Use PDF to maintain formatting across different devices, unless specified otherwise in the job posting.

Crafting a Compelling Resume Summary or Objective for Machinists

The resume summary or objective is a crucial element, serving as your first opportunity to capture the hiring manager's attention. For a machinist, this section should concisely showcase your skills, experience, and what you bring to the table. Here's how to craft a compelling summary or objective:

Resume Summary for an Experienced Machinist

Ideal for those with several years of experience in machining: Highlight your key achievements, skills, and what you can contribute to the prospective employer. Focus on specific experiences that demonstrate your expertise in machining.

"Dedicated and precision-focused machinist with over 8 years of experience in CNC programming and operation. Proven track record in enhancing production efficiency and accuracy, skilled in advanced CAD/CAM technology, and committed to maintaining high safety standards."

Resume Objective for an Entry-Level Machinist

Ideal for newcomers or those shifting careers: Instead of extensive experience, focus on your career goals, relevant skills, and how they align with the job requirements. Showcase your enthusiasm and potential.

"Aspiring machinist with a strong foundation in CNC operation and CAD/CAM programming from extensive coursework and hands-on training. Eager to apply my technical skills and commitment to precision in a challenging manufacturing environment"

Tips for Writing an Effective Summary or Objective

Tailor it to the Job: Customize your summary or objective to align with the specific requirements of the machinist position you're applying for.

Be Specific: Use concrete examples and quantify achievements where possible.

Keep it Concise: Aim for 3-4 impactful sentences.

Focus on Value: Highlight how you can contribute to the employer, not just what you want out of the job.

Detailing Your Work Experience: A Machinist's Guide

The Work Experience section is where you get to showcase your professional journey and achievements. For a machinist's resume, it's important to detail your experiences in a way that highlights your skills, precision, and contributions to past employers. Here's how to structure this section effectively:

How to List Your Machinist Work Experience

1. Reverse Chronological Order: Start with your most recent job and work backwards. This format is preferred by employers as it provides a clear picture of your career progression.

2. Job Title, Employer, and Dates: Clearly state your job title, the company's name, and the duration of your employment.

3. Responsibilities and Achievements: For each role, list your key responsibilities and achievements. Focus on tasks that are relevant to a machinist's role and use action verbs to start each point.

- "Operated and maintained CNC machinery, achieving a 99.7% accuracy rate in produced parts."

- "Collaborated on a project to improve machine efficiency, resulting in a 15% reduction in production time."

Tips for Highlighting Machinist Work Experience

Quantify Your Impact: Wherever possible, use numbers to quantify your achievements, such as efficiency improvements or accuracy rates.

Tailor to the Job Description: Align your experience with the skills and requirements listed in the job description you're applying for.

Focus on Relevant Skills: Highlight experiences that showcase your machining skills, technical knowledge, and any specialty areas like CNC programming or precision machining.

Navigating the Education Section for Machinists

The Education section on a machinist's resume is a vital component, particularly in a field where technical know-how and precision are paramount. Here's how to effectively present your educational background:

Presenting Your Educational Background

1. List of Qualifications: Include any degrees, diplomas, or certificates relevant to machining. Focus on programs that have equipped you with the skills needed in a machinist role.

2. Technical and Vocational Training: If you have undergone specialized training, such as CNC programming or precision machining courses, make sure to highlight these.

3. Recent Graduates: If you're newly entering the field, place more emphasis on your education. Include details like relevant coursework, projects, or extracurricular activities that demonstrate your skills and interest in machining.

A.A.S. in Machining Technology Houston Community College, Houston, TX Graduated May 2022

- CNC Programming

- Precision Machining

- CAD/CAM, Machine Tool Operation

Tips for the Education Section

Relevance is Key: Focus on education and training that is directly relevant to a machinist's role.

Continuing Education: If you have pursued any continuing education or professional development courses, include them to show your commitment to staying current in the field.

Certifications: Include any industry-recognized certifications, such as the National Institute for Metalworking Skills (NIMS) certification, as these can be particularly appealing to employers.

Your Education section should mirror your professional readiness and your dedication to the craft of machining.

Highlighting Skills for a Machinist Resume

In the Skills section, you get to showcase the specific abilities that make you a great fit for a machinist role. This section should be a mix of technical competencies and soft skills relevant to the manufacturing and warehousing sector.

Essential Skills for a Machinist

1. Technical Skills: Include specific machinist skills like CNC programming, manual machining, precision measurement, and blueprint reading. Highlight your proficiency with different machinery and tools.

2. Soft Skills: Machinists also need strong problem-solving skills, attention to detail, and the ability to work in a team. These are just as important as technical skills.

3. Safety and Quality Control: Emphasize your knowledge of safety protocols and quality control standards, which are crucial in a manufacturing environment.

- CNC Programming and Operation

- Manual Lathe and Milling Machine Operation

- Precision Measurement and Quality Control

- Blueprint Reading and Interpretation

- Team Collaboration and Communication

- Strong Problem-Solving Abilities

- Adherence to Safety Standards

Tips for the Skills Section

Tailor to the Job Description: Match your skills with the requirements listed in the job posting. This shows you're a good fit for the role.

Be Specific: Instead of general terms like "machining skills," list specific abilities and machinery you're experienced with.

Balance Technical and Soft Skills: While technical skills are key, don't underestimate the importance of soft skills in a collaborative work environment.

This section is your opportunity to highlight the unique skills that make you an ideal candidate for a machinist position.

Adding Value with Additional Sections on a Machinist Resume