20 Inventory Management Challenges and Solutions for 2022 and Beyond

The lifeblood of your business is getting your products to your customers on time. And staying on top of your inventory and managing it efficiently helps you meet demand and generate sales. We’ll walk through some of the common inventory management challenges—and how to overcome them. To learn more, read our inventory management article .

20 Common Inventory Management Challenges

Managing inventory is a daunting task. The process and results impact every aspect of your business. To help, here are 20 common inventory management challenges to watch for in your supply chain.

Inconsistent Tracking:

Using manual inventory tracking procedures across different software and spreadsheets is time-consuming, redundant and vulnerable to errors. Even small businesses can benefit from a centralized inventory tracking system that includes accounting features.

Warehouse Efficiency:

Inventory management controls at the warehouse is labor-intensive and involves several steps, including receiving and putaway, picking, packing and shipping. The challenge is to perform all these tasks in the most efficient way possible.

Inaccurate Data:

You need to know, at any given moment, exactly what inventory you have. Gone are the days when inventory could be counted once a year with an all-hands-on-deck approach.

Changing Demand:

Customer demand is constantly shifting. Keeping too much could result in obsolete inventory you’re unable to sell, while keeping too little could leave you unable to fulfill customer orders. Order strategies for core items, as well as technology to create and execute an inventory plan, can help compensate for changing demand.

Limited Visibility:

When your inventory is hard to identify or locate in the warehouse, it leads to incomplete, inaccurate or delayed shipments. Receiving and finding the right stock is vital to efficient warehouse operations and positive customer experiences.

Manual Documentation:

Managing inventory with paperwork and manual processes is tedious and not secure. And it doesn’t easily scale across multiple warehouses with lots of stock.

Problem Stock:

Perishable and fragile stock need specialized plans for care and storage. And high-value inventory needs specific loss-prevention strategies and inventory controls.

Supply Chain Complexity:

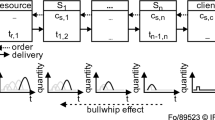

Global supply chains shift daily , placing a burden on your inventory planning and management operations. The manufacturers and wholesale distributors that dictate when, where and how your inventory ships require flexibility and offer unpredictable lead times.

Managing Warehouse Space:

Efficiently managing space is an intimidating task. Planning and designing warehouse spaces with inventory management platforms helps you better control the timing of new stock deliveries. It can account for important factors, such as available space. Read more about the differences between warehouse management and inventory management.

Insufficient Order Management:

One of the most common challenges to sound inventory management is preventing the overselling of products and running out of inventory. Using historical and seasonal data trends can help you accurately predict customer orders.

Increasing Competition:

Globalized supply chains are subject to unpredictable economic shifts and market forces that impact the competition for raw materials. Small businesses are sometimes faced with choosing between competing for high-demand materials or holding enough inventory to control costs.

Evolving Packaging:

Compostable packaging—or removing packaging all together—to reduce waste presents new obstacles for warehouse design and storage. It may even mean new equipment or shorter shelf life for some items.

Expanding Product Portfolios:

Many online retail strategies remove the need for large warehouse distribution centers. These strategies make it easier to expand inventory and diversify product portfolios, but demand technology and resources for ordering, shipping and tracking.

Overstocking:

Keeping too much stock on hand can be as problematic as having too little. Overstock impacts business cash flow and leads to inventory-related problems, such as storage and loss.

Inventory Loss:

The loss of inventory due to spoilage, damage or theft can be a supply chain problem. It requires identifying, tracking and measuring problem areas.

Poor Production Planning:

Production planning is vital for avoiding delayed manufacturing and cost overruns. If not done well, it can impact sales forecasts and project scheduling.

Lack of Expertise:

It can be tough to find skilled inventory managers who are adept at the latest technology and can improve inventory strategy. Simply upgrading your inventory management platform with a host of features isn’t enough. You need capable management.

Poor Communication:

Communication and collaboration are key. When departments are apathetic about sharing information, it makes identifying inventory trends and finding ways to improve much more difficult.

Inefficient Processes:

Low-tech, manual inventory management procedures don’t seem like a daunting challenge when inventory is small and there’s only one warehouse location to manage. But as sales volume increases and inventory expands, inefficient, labor-intensive and low-tech standard operating procedures are difficult to scale.

Inadequate Software:

To scale inventory management software to support complex logistics, it needs to integrate with your existing business process platforms. The difficult task is choosing from hundreds of inventory management solutions and mastering a host of features that require training and ongoing support.

Award Winning Cloud Inventory

20 Solutions to Overcome Inventory Management Challenges

Inventory management is immensely complex. Here are some solutions to the common inventory management challenges listed above.

Centralized Tracking:

Consider upgrading to tracking software that provides automated features for re-ordering and procurement. Inventory management platforms provide centralized, cloud-based databases for accurate, automatic inventory updates and real-time data backup.

Transparent Performance:

Measure and report warehouse performance metrics like inventory turnover, customer satisfaction and order processing speed to overcome warehouse inefficiencies. Share this data with employees and suppliers.

Stock Auditing:

Frequent stock auditing processes, like daily cycle counting, reduce human error and provide more accurate, up-to-date inventory data for managing cash flow . Organize audits by category and cycle count smaller inventory samples on a predictable schedule for more accurate financial data.

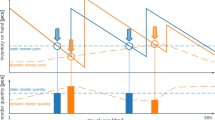

Demand Forecasting:

Some inventory management platforms include demand forecasting tools. This feature integrates with accounting and sales data to help you predict demand and schedule orders based on shifting customer preferences, material availability or seasonal trends.

Add Imagery:

Add images with product descriptions in your inventory database to improve purchasing and receiving processes, enhance accuracy and prevent misplaced inventory.

Go Paperless:

Give employees the right inventory tools for the job. They need software to replace manual inventory documentation, and paperless transactions for invoices and purchase orders.

Preventive Control:

Implement stock control systems to manage problem inventory, such as perishable stock, fragile equipment or obsolete materials. Perform regular preventive maintenance on machinery and equipment stock in storage if required by the manufacturer. Catalog data on problem stock location, cost and quantity to monitor shelf life and prevent waste.

Measure Service Levels:

Monitor and track supplier data, such as shipment errors, damaged or defective products and missed delivery appointments. Measure your supplier’s performance to find and fix supply chain disruptions , reduce complexity and streamline logistics.

Optimize Space:

Use inventory management systems with warehouse management features to optimize storage space and inventory flow. Categorize inventory storage down to shelf, bin and compartment, and automate order picking, packing and shipping workflows.

Automate Reorders:

Backordered inventory delays production and creates poor customer experiences. Use inventory management software to set automatic reorder points based on preset stock levels and current availability to avoid overselling.

Safety Stock:

Maintain safety stock to offset supply chain disruptions and help manage increased lead times due to shifting international competition for raw materials. Proper inventory planning helps operations adapt to dynamic global supply chains.

Classify Inventory:

Create inventory classifications to manage changing trends, such as packaging initiatives to reduce plastic waste. Categorize stock by packaging type, dimensions and product. Use this information to control shipping costs and storage location better.

Multi-Location Warehousing:

Use multi-location warehouse management features to track and control expanding inventories. Take advantage of receiving and put-away schedules with automated inventory tracking alerts and scheduling features that keep tabs on warehouse location and in-transit inventory .

Leverage Lead Times:

Take lead times into account when placing orders for high-demand stock. Track and manage your high-demand inventory using cycle counting data to set automatic reorder points and average lead time to preventing stockouts .

Reduce Human Error:

Use inventory control processes like blind receiving with barcodes and mobile scanners to prevent human error, inventory manipulation and shrinkage due to theft or negligence.

Plan Demand:

Use an inventory management system with advanced demand forecasting and reporting features to prioritize your top inventory. Take into account the availability of the top 20% of inventory that generates 80% of your customer demand. To learn more about inventory planning and demand forecasting, read our essential guide to inventory planning .

Subcontract Expertise:

Consider outsourcing to an expert in inventory management. Contract in-person training and provide online support to help employees follow best practices for working with technical inventory management software features.

Dashboard Collaboration:

Introduce dashboards with simple interfaces that show real-time inventory data. Having everything on one screen helps remove communication barriers across accounting, sales and warehouse operations.

Productivity Tools:

All the information you need about your inventory can be in your pocket. With mobile solutions and cloud-based software, you can control inventory and improve your warehouse productivity from anywhere in the world.

Update Platforms:

Upgrading to a cloud-based inventory management platform doesn’t just give all the latest features. You get to take advantage of the vendor’s expertise and training while it’s being implemented.

Summary of Inventory Management Challenges and Solutions

Use this quick-reference chart to review common inventory management challenges and suggestions for how to overcome them.

Inventory Management

Overcome Challenges With Inventory Management Software

The right inventory management platform can automate processes, improve inventory practices and enhance customer experiences. NetSuite offers a collection of native inventory management and control features to help overcome some of the biggest inventory management challenges. Track inventory across multiple locations, automatically manage reorder points, forecast demand and plan production and distribution.

Just-in-Time vs Just-in-Case: Choosing the Right Strategy

Just-in-time (JIT) and just-in-case (JIC) are on opposite ends of the inventory philosophy spectrum: One aims for lean operations, the other makes stockpiling a priority. Both are commonly employed in manufacturing and…

Trending Articles

Learn How NetSuite Can Streamline Your Business

NetSuite has packaged the experience gained from tens of thousands of worldwide deployments over two decades into a set of leading practices that pave a clear path to success and are proven to deliver rapid business value. With NetSuite, you go live in a predictable timeframe — smart, stepped implementations begin with sales and span the entire customer lifecycle, so there’s continuity from sales to services to support.

Before you go...

Discover the products that 37,000+ customers depend on to fuel their growth.

Before you go. Talk with our team or check out these resources.

Want to set up a chat later? Let us do the lifting.

NetSuite ERP

Explore what NetSuite ERP can do for you.

Business Guide

Complete Guide to Cloud ERP Implementation

7 Inventory Control Problems and How to Solve Them

Home -> Inventory Management -> 7 Inventory Control Problems and How to Solve Them

Inventory control can affect sales, budgets, customer satisfaction, and so much more. From being able to access inventory quickly to always having enough items in stock, inventory control is a complex topic. While you may have to make some mistakes on your own, you should try to avoid mistakes where you can.

What is inventory control?

Inventory control refers to all aspects of managing your company’s stock levels and getting these products to customers as expected. The most important aspect of inventory control is ensuring accurate and sufficient stock levels in order to keep up with consumer demand. This process may be done in-house or through a third-party company such as a logistics provider or order fulfillment warehouse. The use of fully automated inventory control systems allows retail companies to successfully manage their inventory without costly mistakes or issues.

Why inventory control is important in business

Inventory control is one of the most important aspects of any products-based business. Failure to properly manage your inventory and successfully fulfill orders can lead to all sorts of costly issues and cut into your potential profits. Understanding how to manage your inventory and avoid inventory control problems is the key to your future business success and profitability.

Most Common Inventory Control Problems

While there are many things that can go wrong when it comes to inventory control, the most common problems that small businesses encounter are as follows.

- Understocking or overstocking : Understock and overstocking can both be costly mistakes. In some cases they are a result of negligence, while in other cases they may be a result of poor inventory control or cash flow restraints. Understocking most commonly results from cash flow challenges or supplier problems. Both of these issues can easily be fixed, but before you dive in make sure you are managing inventory properly and know exactly what you need. On the other hand, overstocking occurs when too much inventory is purchased. If you don’t have adequate inventory tracking systems in place it’s easy to overstock inventory on accident. The sooner you acknowledge that you’re overstocked, the better. Make efforts to liquidate some inventory or devise a plan for moving it. Overstocking and understocking can affect your bottom line through lost profits, tied-up cash flow, and missed sales. Utilizing a robust inventory management system in conjunction with analytics can help prevent these costly issues.

- Supply chain difficulties : Retail businesses are often at the mercy of their suppliers. Issues with your supply chain can lead to shipping delays, product shortages, the inability to fulfill orders, and other challenges to keeping up with consumer demand. These issues also affect customer satisfaction and can hurt your company’s reputation. It may sound scary to jump ship, but trying a new supplier may be necessary. Before switching, be sure to vet the new supplier. Asking to speak with current customers can be a great way to gather real insight.

- Inaccurate stock : You can’t sell a product that isn’t actually on your shelf. A lack of automation and lack of communication between your warehouse and your website can lead to mistakes in your inventory count and inaccurate stock levels. While it may require investment, having accurate real-time data helps you spot problems and keep customers happy.

- Demand complexity : There are many factors involved in proper inventory control. Businesses must remember to account for these factors including demand volatility, seasonal fluctuations, product life cycles, and supply chain complexities. These challenges can make it difficult to plan for and maintain the right amount of inventory.

- Lack of communication : If different departments of your business are not properly communicating with each other, you will be much more likely to encounter inventory control issues. For example, whoever is in charge of purchase decisions should be kept informed of every aspect of inventory management from the current state of the warehouse to any anticipated changes in market conditions or seasonal demand. The right technology can increase this visibility and cooperation between everyone involved.

- Lack of automation : If your company is still relying on paperwork and other manual systems, you may be missing a key opportunity to take your business to the next level. A lack of automation can be financially costly, take up too much time, lead to mistakes in data entry, and allow important information to fall through the cracks. On the other hand, the right inventory management system can allow key employees throughout the organization to stay informed and equipped with real-time (and accurate) data. A fully automated and integrated inventory management system is always the best choice.

- Lack of experienced staff : When you’re running a product-based business, it’s key that all employees involved in inventory management, logistics, and order fulfillment are experienced and trained. Having knowledgeable staff will help your company quickly identify any inventory control problems and prevent them from happening in the first place. On the other hand, inexperienced staff can lead to damaged goods, inaccurate data, and poor business decisions. Remember that staff is at the forefront of inventory issues. Hire individuals you trust and are competent, even if that means paying them more. Furthermore, meet with them regularly to find out what’s working and what’s not.

Tips for solving inventory control issues

Luckily, there are many things your business can do to stay on top of inventory management and avoid the most common inventory control problems. Consider these valuable tips below to help you maximize productivity and profits.

- Consider outsourcing: Not all companies have the ability to manage their inventory themselves, especially small businesses who are just getting started. For these retail companies, hiring a third-party company who can expertly handle all of your logistics, inventory management, and order fulfillment can be a smart move. As an added bonus, leaving your inventory control to the experts frees you up to focus on other aspects of your business.

- Incorporate analytics : In order to avoid common inventory control issues such as understocking and overstocking, all of your business decisions should be data-driven. Utilizing consumer analytics and inventory management KPIs will help your company avoid these issues. The right data allows you to make informed business decisions, forecast for future demand, account for seasonality, track product sales cycles, and maintain accurate inventory levels. Companies should also have a solid understanding of their target customer and current market conditions.

- Incorporate technology : The use of automation, real-time inventory tracking software, and other technology can help your company stay on top of inventory control. Product visibility is extremely important to avoid understocking, overstocking, and inaccurate stock levels, so consider replacing any outdated systems with the latest solutions. Investing in the latest technology becomes even more important if you are managing your inventory remotely across several locations. Your inventory management system should be able to scale with your business, provide accurate information in real-time, and be accessible to employees throughout your organization anywhere in the world.

- Invest in employee training : The more skilled and knowledgeable your employees are, the more equipped your company will be to handle logistics, order fulfillment, analytics, forecasting, and inventory management. An investment in the continued education and training of your staff is never wasted.

- Keep up with trends: Industry knowledge is especially important for retail business owners. In order to make the best business decisions and avoid issues with your inventory levels, be sure to stay up to date with current market conditions and trends.

How Kickfurther can help

A lack of cash flow can hinder many retail companies from ordering the stock they need to remain both competitive and profitable. Kickfurther helps companies secure the funding they need for inventory. As the world’s first online funding platform that enables companies access to funds they are unable to acquire through traditional sources, we understand the struggles small business owners face.

For companies that sell physical products or non-perishable consumables and have revenue between $150k to $15mm over the last 12 months, Kickfurther can help. We connect brands to a community of backers who help fund inventory on consignment and give brands flexibility to pay that back as they receive cash from sales.

Kickfurther can help startups fund millions of dollars of inventory at costs up to 30% cheaper than the competition. With more than $100 million in inventory funded to date, Kickfurther can help you get funded within a day or even minutes to hours.

Inventory control is critical for profits, customer satisfaction, and all business operations. In business it’s easy to overlook a few problems, but remember, that one problem will turn into more. If financial restraints are the cause of inventory control issues, take charge. By utilizing inventory funding through Kickfurther combined with staffing the right people and implementing efficient inventory management systems, you can maximize the potential of your business.

Interested in getting funded at Kickfurther ? Here are 3 easy steps to get started:

#1. Create a free business account

#2. Complete the online application

#3. Review a potential deal with one of our account reps & get funded in minutes

- Ecommerce 37

- Funding Solutions 10

- Import & Export Finance 13

- Inventory Financing 50

- Inventory Management 27

- Manufacturing 7

- Small Business 53

- Snowmelt 10

- Supply Chain 20

- Uncategorized 1

How much funding could your company raise?

Submit this form to see your estimate.

Amazon Seller Financing

Nail salon supply distributor financing, purchase order financing, shopify capital for financing, startup inventory financing, walmart inventory financing, e-commerce financing, ebay seller financing, warehouse inventory financing, food & beverage inventory financing, inventory finance for small business, wholesale inventory financing & loans, newegg inventory financing, supply chain financing, apparel brand financing, cosmetics & beauty financing, cbd business financing, pet store financing, retail business financing, sporting goods retail financing, revenue based financing, exercise & gym equipment financing, fragrance business financing, fashion accessories industry financing, hair care business inventory financing, supplier financing, home decor brand industry financing, mocktail mixes industry financing, healthcare business financing, coffee shop inventory financing, seasonal business industry financing, fashion jewelry inventory financing, business financing for technology companies, inventory financing for electronics brands, accounts receivable factoring, wellness center inventory financing, baby care product supplier financing, online grocery & foods retailer inventory financing, inventory financing for dropship businesses, inventory financing for women entrepreneurs, financing for furniture companies, medical supplier financing, dietary supplement business financing, previous post best inventory demand forecasting techniques, next post how much inventory should you carry, related posts.

Partner Directory

Screening Process

Privacy Policy

Terms of use

Stores Terms of Service

- Help Center

Report an issue

Subscribe to our newsletter

Sign up to get the latest news and updates.

Stay Connected

© 2024 Ouiby Inc. DBA Kickfurther

- How it Works

- Success Stories

- Distributors

- Marketplace

- Join Our Funding Marketplace

- +966 13 848 8080

- [email protected]

- Sun-Thu:9AM to 6PM

Top Inventory Management Challenges and How Best to Solve them

Inventory is the lifeblood of any business that deals with products, and it is vital that you manage it efficiently for business success and growth.

The challenges of inventory management are several.

The right solution can help you boost profitability and deliver outstanding customer service.

This is regardless of what the inventory location is – one warehouse or several; or even supplier drop-shipping.

Proper management of inventory helps cut costs, enhance cash flow, and ensure continuous production, and fulfilment of customer orders in time.

Partnering with a reputed service provider like Tranquil can mean the difference between chaos and seamlessness.

Staying on top of your inventory will allow you to generate sales , fulfil customer demands, and maintain business continuity.

Let us take a look at the most common inventory management problems and solutions .

ALSO READ: Common ERP Challenges in 2022

Common Inventory Management Problems and Solutions

1. lack of inventory visibility.

If you’re unable to locate or identify stocks in your inventory, shipping products on time becomes very difficult, and this can dent your business reputation.

Inventory that is incomplete, difficult to find, or erroneous, is sure to hamper your bottom line.

In fact, the most common reason for delayed, wrong, or partial shipments is the difficulty of locating or identifying inventory in the warehouse.

Receiving in finding the correct stock is critical for ensuring warehouse efficiency, as well as good experiences for the customer.

Solution: Real-time inventory management system

When you implement a real-time inventory management system like Tranquil ERP, you will have all the accurate details regarding location data, and stock availability.

This will help in the easy location of stocks, which ultimately translates to better order fulfilment and customer satisfaction.

ALSO READ: Pipeline Inventory and Decoupling Inventory

2. Inefficient Inventory Management Process or Software

This is probably the most common, and the biggest inventory challenges .

Many businesses still try to manage their inventory with manual procedures, or outdated legacy software – which may stunt your business growth.

It may not seem much of a bother to use manual, labor-intensive, or low-tech systems when you’re a small, one-warehouse business – but that will change when you expand.

When sales volumes balloon, you need to expand inventory and add warehouses.

Old and inefficient inventory management practices will be tough to scale, and prove to be a handicap, and not give you the results you need.

Manual inventory tracking procedures involve either paperwork or tracking procedures across multiple spreadsheets and software, which can lead to data redundancy, incomplete data, and a lot of time spent on it; it also provides less security.

In today’s competitive age, it is essential to know at any point in time, exactly what inventory you have; you can no longer rely on physically counting inventory annually using all your employees.

Another big problem is inventory loss caused by theft, damage, spoilage, and so on; this supply chain issue requires the ability to properly pinpoint, track, and measure the problem areas.

You can scale inventory management software and support complicated logistics, only when you are able to integrate it with your existing business software.

This cannot be achieved with outdated, legacy systems.

Solution: IoT-driven inventory management solution

ALSO READ: What are Backorders and How to Manage or Avoid Them?

An inventory management system that leverages IoT will empower your warehouse staff, and help them manage stocks and track them throughout their time in your warehouse efficiently, and quickly.

You can streamline your inventory management with the right solution, and enhance inventory efficiency.

It’s not just large corporations, but even small businesses that can benefit from a centralized inventory tracking system with integrated accounting features – all of which can be found in Tranquil ERP; it is robust, intuitive, economical, flexible, and scalable.

3. Tracking Obsolete Material

In almost every business, you are likely to face this problem at some time or the other.

There will be some products or materials that remain unsold or unused, and they may become obsolete, or past their expiry date.

These materials or products tend to accumulate over time as they are mostly ignored by inventory managers.

When that product or material is needed sometime in the future, unfortunately, the unsold stock stays forgotten, and new stock is purchased; the older one may remain in the warehouse for so long that it gets damaged completely.

This increases expenses, and material wastage.

Solution: Efficient stock control system

ALSO READ: What is Negative Inventory?

This feature is included in the Inventory management module of Tranquil ERP.

You will be able to locate the dead stock and make proper use of them.

Such a software solution can help inventory managers significantly in controlling stocks.

4. Identifying Incorrectly Located Materials

When there is no proper system to track products, materials, or equipment in the store, it can be cumbersome and time-consuming to find them when you have sales orders.

After all, a warehouse may typically store thousands of products. This can delay sales and make customers unhappy.

Solution : Product finder

All products that you have should be tagged with RFID , barcodes, or QR codes etched with a laser.

This will help your employees identify the products that are needed.

They only need to be equipped with a scanner. Once the scanner finds the required product, a lamp glows, indicating a match.

This helps your pickers to quickly find the product and send it to the sales agents, saving them time, speeding up the sales cycle, and making customers happy.

ALSO READ: Route and Van Sales – Challenges and Opportunities

5. Keeping up with Overstocks

When you purchase new materials with a few unsold products lying in your warehouse, it can affect your profitability.

This situation mostly arises due to the inefficiencies of manual processes, which causes poor control of stock.

Storing too much stock is as bad as storing too little, as overstocking hampers your cash flow and creates problems related to inventory, like storage, or loss.

Solution : Stock audit process

When you implement a stock audit process, inventory managers will be able to audit stocks regularly so that unused stocks are quickly identified.

This boosts the efficiency of inventory greatly, enabling your company to cut costs, eliminate delays, and enhance profitability.

6. Managing Inventory Waste & Defects

Though it may seem small, it is one of the most common and repetitive inventory management problems that can cause huge losses eventually.

To be able to fulfil orders in time, it is essential that you maintain optimal inventory.

Without standard procedures and untrained operators, you could end up with inventory that gets damaged or wasted – and this can not only prove to be very expensive but also lead to dissatisfied customers.

Solution : Modern inventory management software

Tranquil ERP has a robust inventory management module that enables you to manage and control your inventory efficiently.

With streamlining of procedures and processes, your employees will find it easy to perform their jobs, and you can cut costs and eliminate wastage.

ALSO READ: Guide on Procurement Challenges

7. Lack of Centralized Inventory Hub

Stocktaking becomes very challenging when you have inventories in multiple locations.

Discrete stock data from various locations makes shipping complex, resulting in delays.

It’s one of the biggest and continual challenges faced by most businesses today.

Solution : Central inventory system

You can significantly reduce expenses and save a great deal of time by simply creating a centralized inventory hub for your inventory-related data, including stock-taking.

This gives you comprehensive visibility and control of inventory and data in one single location, making stock management simple.

It also becomes much easier to track the inventory that enters and leaves your business premises.

8. Changing Demand

Consumer demand is in a constant state of flux; this makes storing inventory complicated.

How much to store? Too much, and you could end up with dead stock ; too little, and you won’t be able to fulfill customer demands.

Solution : Technology to Plan Inventory

What you need is robust inventory forecasting technology that takes into consideration all these factors, and helps you plan your inventory more efficiently.

Tranquil ERP’s inventory management module has the forecast feature that helps create and implement the optimal inventory plan.

This can help you to keep up with fluctuating customer demand.

ALSO READ: ERP Configuration vs. ERP Customization vs. ERP Personalization

9. Supply Chain Complexity

International supply chains are dynamic and can create roadblocks in the management and planning of your inventory.

Manufacturers and distributors are impacted by unforeseen economic booms and slumps which impact raw material prices and availability.

They also decide when, how, and where to ship the inventory – and this means you have lead times that you cannot predict, necessitating you to be much more flexible.

Solution : Robust Inventory Management application

With the right inventory management application implemented in your business, you can predict lead times as close to accuracy as possible, and be better prepared to handle supply chain complexities.

10. Managing Warehouse Space and Efficiency

One of the most challenging tasks for any business is the efficient management of space.

Warehouses need to be planned and designed with the help of inventory management platforms so that you can control when new stock is delivered, and help you make the best use of available space.

If you deal in fragile or perishable products, you need to arrange specialized care and storage – for example, cold storage.

You have to implement specific strategies for expensive inventory, to prevent theft and damage.

Warehouse inventory control is labor-intensive, and necessitates multiple steps like receiving the stocks, putting them away, picking inventory, packing, and finally, shipping.

It is critical that all of these tasks are executed as efficiently as possible.

ALSO READ: What is Business Process Improvement (BPI)?

Solution : Warehouse Management System

Inventory management modules either have warehouse management as a feature or are integrated with warehouse management modules.

This can help you automate many of the tedious tasks and bring in more efficiency in the entire warehouse management of your business.

11. Insufficient Order Management and Poor Production Planning:

Production planning is of critical importance if you don’t want to have a stoppage of production and cause budget overflows.

If you don’t plan it appropriately, your sales forecasts can go haywire, as can your project scheduling.

Thinking that there is sufficient stock, and overselling products is a common challenge faced by many businesses.

Solution : Production planning software

Production planning software makes use of seasonal trends, and historical data to make fairly accurate predictions that help you plan production better.

12. Lack of Expertise and Poor communication

While every business would love to have inventory managers who are excellent communicators and tech-savvy, taking to new technology easily, the truth is that it seldom happens that way.

Merely deploying the most feature-packed ERP system will not cut it if it’s not used properly.

Solution : Proper Training

From the outset, importance should be given to imparting proper training to all those who will use the new system.

It should be especially impressed upon the managers that they need to familiarize themselves with the new system properly.

The different department heads should also be told about the importance of collaboration and sharing data.

Disparate solutions for every process can cause confusion and improper data. A one-stop solution like Tranquil ERP can help you decrease wastage of materials, and attain more efficiencies in your inventory management , and across your organization. Tranquil is a robust, cutting-edge ERP solution deployed in the cloud that helps you maximize your inventory usage. Schedule a demo with us to know how our software works and how it can benefit your business.

- What is HCM and How Does it Differ from HRM?

- Why is ERP System For Automotive Industry Important?

- How Does ERP Deliver ROI for Business?

- How to Choose an ERP Software to Enhance your Purchase Management

- Detailed Guide on ERP in Production Planning

- Business tips

- HR & Payroll

- Small business

- General Trading

- Manufacturing

- Distribution

- Project Management

Request A Demo

7 Common Inventory Management Errors (And How to Avoid Them)

These costly mistakes will cut into your bottom line—but luckily they’re easy to avoid..

Inventory management errors may be costing your business more than you think. You might measure this cost in wasted time, frustration, or lost customers. But ultimately, it all boils down to financial losses that are easily avoidable with the right strategies in place.

In this article, we’ll dig into the most common inventory management errors faced by both traditional retailers and e-commerce businesses. We’ll also discuss strategies for avoiding these missteps so you can make the most of your inventory investment.

Why Inventory Management Errors Matter—A Lot

Are you managing your inventory, or is your inventory managing you? Sometimes it can feel like the latter when you don’t have a solid inventory management system in place, and it’s easy to see why. One simple error can cause a domino effect of consequences for your business.

Poorly managed inventory causes frustrations for customers, ranging from out-of-stock items to longer shipping times due to lack of product availability. It can also lead to overstocks, stockouts, and inefficient use of warehouse space during a time when industrial real estate is at a premium.

In turn, these problems can have a ripple effect on your business. It may cause customers to shop elsewhere, meaning a loss in sales and eventually, a damaged brand reputation. That’s why it’s important to focus on avoiding common inventory management errors that hurt your bottom line.

On the flip side, the benefits of good inventory control and management include reduced costs and increased profits, improved stock availability, and faster fulfillment, all of which lead to happier customers.

The 7 Most Common Inventory Management Errors

These are the most common inventory management errors that businesses make—and odds are that if you’re making one of them, you’re probably making a few others as well. Many of these errors stem from the same root cause: a lack of solid systems for inventory management . That’s why many of these errors are interlinked with each other. The upside of this is that by tackling these core issues and following inventory management best practices , you’ll go a long way towards resolving most of these errors.

1. A Lack of Planning

There’s an old saying about planning: “If you fail to plan, you’re planning to fail.” That’s certainly the case with inventory management. If you don’t have a solid inventory management process in place, it can be difficult to anticipate customer demand or manage your stock levels correctly.

Without proper forecasting, you won’t know when certain products are running low or how much of each item to order. This can result in overstocking and stockouts, both of which mean lost sales and revenue.

How to Avoid It:

Make sure you have an up-to-date forecast that allows you to anticipate customer demand based on past and current product performance, then use this forecast to adjust your stock levels accordingly. Also, consider using tools like inventory optimization software or a supply chain visibility platform to help you better manage your inventory levels by measuring stock levels and product trends.

2. Foregoing Automation

Inventory management can be a daunting task, and manual processes are both time-consuming and prone to errors. Without automation, it’s nearly impossible to keep track of all your inventory with accuracy and efficiency.

Whether you have some haphazard automation in place or you’re still managing everything manually in Excel, you’re at risk of making costly mistakes by sleeping on the business-boosting benefits of automating your inventory management. These days, automation is a must for any business that wants to keep up with the competition.

Look into tools like inventory management software, demand planning software, and warehouse automation solutions to help you automate your entire inventory management process. You’ll be able to easily track stock levels, keep on top of ordering, identify up-and-coming trends in customer demand, and more. Automation can also help you identify and address issues more quickly so you don’t suffer the consequences of an inventory blunder for too long.

3. Poor Organization

Your warehouse should be organized and optimized for maximum efficiency. If it’s not, your inventory management is likely suffering.

Unfortunately, a lack of organization is an issue that can easily snowball. It’s a little bit like a teenager with a messy bedroom—the more disorganized your warehouse is, the more disorganized it’s likely to be in the future if you don’t make any changes. And, the more likely you are to make costly mistakes with a warehouse in chaos.

Poor organization and poorly thought-out processes can cause inaccurate stock counts, lost items, incorrect location tracking, or even safety issues for warehouse employees. It can also lead to inefficiencies—for example, if your most popular item is stored high out of reach, it’s slowing down your order pickers. The longer you wait to get things in order, the more significant these errors will be.

Implement an efficient warehouse organization system to make sure everything is in its proper place and easily found when needed. Investing in warehouse automation can also help improve organization and accuracy. With automated systems that track inventory, you’ll always know where things are located and how much of each item is in stock.

4. Unqualified Employees

Automation isn’t the answer to all of your inventory management problems. You’ll also need to make sure you have the right people on board; once they’re in place, it’s time to invest in training them.

Employees who aren’t properly trained in inventory management processes or systems can introduce costly errors into your inventory system. For example, they may not know how to use certain software correctly, resulting in incorrect data entry or inaccurate stock counts. Even with an intuitive inventory system, training is critical. Employees who feel confident on the job are also happier on the job, which means better performance.

Proper training is key to ensuring your employees can effectively manage and track inventory. Be sure to provide them with training in any automated systems you’re using, as well as regular refresher courses. Many software providers offer online resources, like how-to videos, blogs, tutorials, and other content . Take advantage of these ready-made resources to help your people improve performance. Additionally, make sure relevant staff are familiar with the processes related to ordering, stocking, tracking, and shipping inventory accurately and efficiently.

Depending on the size of your business, you may also want to consider hiring a dedicated inventory manager. With a firm grip on all of your inventory processes, hiring someone in this role can be a game-changer as you work to scale up your business and optimize your inventory management.

5. Under- and Over-Stocking Items

This may circle back to a failure to forecast, but it’s worth mentioning on its own. Both under-stocking and over-stocking items can have a big impact on your business. If you’re not stocking enough of an item, you could miss out on sales due to stockouts. On the other hand, if you’re stocking too much of something, it could lead to extra storage costs and wasted space in your warehouse.

Don’t just focus on the number of items you have in stock—you also need to make sure your inventory mix is balanced and that you’re carrying items that customers actually want. Jeff Bezos , who may know a thing or two about inventory management, encourages businesses to “determine what your customers need, and work backward.”

Forecasting is key to avoiding overstocking and under-stocking items. Make sure you’re looking at historical sales data, inventory levels, current trends, customer demand, seasonality, and any other factors to establish reorder points. Consider investing in an inventory optimization tool or a supply chain visibility platform to help you gain more insight into your inventory so you can make smarter stocking decisions.

6. Lack of Performance Measurements

If you don’t have any performance measurements or auditing in place, it can be difficult to identify issues with your inventory management systems. Without these metrics, there’s really no way to tell if your processes are working as they should, or if there are any bottlenecks that need to be addressed—at least not until something disastrous happens.

Data is critical to any successful inventory management strategy, and without it, you won’t be able to make informed decisions or optimize your processes. There’s no such thing as too much information here.

Make sure you have the right KPIs in place so that you can assess the performance of your inventory management process. This could include everything from stock levels to on-time delivery percentages and more. Regular audits will help you ensure your processes are running smoothly and identify potential issues early on before they escalate into big problems for your business.

7. Poor Vendor Relationships

The relationships you have with your vendors can have a significant impact on the success of your inventory management process. After all, your vendors are the ones who ensure you have the right products at the right time for your customers.

If you don’t have a good relationship with suppliers, it can result in delays in shipments and other issues that disrupt your inventory levels. Poor vendor relationships can also lead to higher costs; a lack of communication can make matters even worse, as you might not have sufficient notice about these issues, leaving you without a Plan B.

Make sure you’re selecting the right vendors and nurturing these relationships through effective supplier relationship management practices . Establish processes for regular communication and use tools like order tracking and electronic data interchange (EDI) to help keep everybody on the same page.

How Inventory Management Software Can Help

While there are many different strategies you can use to improve your inventory management process, one of the best is investing in inventory management software . This business-boosting software can help automate many tedious warehouse and inventory tasks, reduce human error, and provide critical real-time visibility into your stock levels.

Inventory management systems can also make it easier to manage multiple warehouses or locations at once, as well as track orders and supply chain processes. Ultimately, you’ll be able to manage your inventory more effectively and ensure products are delivered to your customers on time.

(Learn more about how inventory management software can optimize your business.)

The Bottom Line

Inventory management errors are costly. They lead to lost sales, dissatisfied customers, and wasted resources. Fortunately, there are several strategies you can use to minimize such errors and ensure your inventory processes run smoothly. These include investing in the right technology, providing proper training for employees, forecasting accurately, and nurturing collaborative relationships with vendors.

Being proactive and tackling these issues head-on will create a more efficient inventory management process and ensure your business runs like a well-oiled machine.

If you’re interested in taking your inventory management strategy to the next level, get in touch . We will be happy to start you on your journey.

Andrew Page

- Agiliron News

- Cloud Computing

- Growing Your Business

- Industry Trends

- Infographics

- Uncategorized

Most Common Inventory Management Problems in 2024 (and Their Solutions)

- Better serve customers

- Optimize operations

- Stay competitive in an ever-changing marketplace

What is inventory management?

- Tracking inventory levels

- Monitoring product demand

- Replenishment

The supporting role of inventory data management

- Values of products held by a retailer

Common inventory management problems and solutions

Explore: 3 Expert Tips to Master Inventory Management for E-commerce

Inventory issues:

1. poor demand forecasting, 2. overstock.

- Excess inventory

- Takes up valuable warehouse space

- Ties up capital

- Obsolete or expired products

- Wasted resources.

3. Understock

4. poor visibility into inventory, 5. inefficient tracking and ordering systems, how to fix inventory problems.

Inventory solutions

1. improve your demand forecasts.

- Analyze large amounts of data

- Identify patterns in sales

- Makes predictions about future sales right down to the SKU level

2. Say goodbye to overstock

3. stop coming up short, 4. let there be sight.

- Sales trends

- Stock levels

- Product performance SKU-by-SKU

5. If you can track it, you can manage it

Apply innovative solutions to overcome inventory management challenges.

- Increase demand forecasting accuracy and efficiency

- Reduce inventory carrying costs from overstock

- Automatically replenish to avoid stockout

- Gain more visibility into your inventory management process

- Track inventory in real-time

Table of Contents

People Also Read

Putting an End to the $50B Overstock Problem with Advanced Analytics

Top 4 Strategies to Maximize Your Sales During A Recession (2024)

How to Win at Ecommerce Demand Forecasting in 2024

Looking to stay up to date on the latest in retail?

Get the latest in retail, artificial intelligence, and business by joining our newsletter.

- About Retalon

- Leadership Team

Connect With Us

- Toll Free : 1.888.837.0268

- Contact Us Online

- Request A Demo

Copyright ©2024 Retalon. All Rights Reserved.

- Toll Free 1800 309 8859 / +91 80 25638240

Home Business Guides Common Inventory Management Problems, Challenges, And Solutions

Common Inventory Management Problems, Challenges, And Solutions

Tally Solutions | Updated on: May 23, 2023

--> published date: | updated on: --> <--, top challenges in managing inventory, how inventory management software can help you overcome challenges.

Inventory management is an essential process in many different businesses ranging from retail sales to manufacturing industries. Good inventory management is crucial to the success of these businesses. Better inventory management improves cash flows and reduces expenses. Some inventory management problems are common across industries.

Visibility problems

When your inventory becomes hard to find, you have inventory visibility problems. Lack of visibility is one of the most common inventory management problems. Locating the correct item in the right place as quickly as possible is essential to inventory. If the hard to find inventory is part of the supply chain for manufacturing, it can impact the operations of the entire manufacturing process. If the inventory stock is being accessed for shipping and cannot be located, it leads to incomplete or wrong shipments and severely impacts customer satisfaction. Either way inventory visibility problems have a severe impact on the performance of the business and is one of the symptoms of poor inventory management.

Lack of real-time reporting

Inventory reports are essential to making decisions. An inventory department cannot summarise and report based on real-time inventory data when using a manual system. Reports on historical trends are also challenging to prepare quickly. When management cannot visualise inventory stock or trends, making informed decisions on purchase and inventory becomes tough. This directly affects the bottom line of the company.

Inefficiency

Managing inventory manually is a cumbersome and tedious process. Even the routine tasks become slower than they should be. As companies scale up, the process becomes more inefficient and slow. Manual inventory management becomes even more challenging to implement across multiple warehouse locations. Inefficient inventory management slows down operations. Inventory management problems that cause slow shipping of products leads to a fall in customer satisfaction. Even when software solutions are used, improperly designed or obsolete systems do nothing more than merely replicate the manual process of inventory management . Inefficiency and redundancy are some of the symptoms of poor inventory management.

Overstocking

Money that is spent on inventory gets locked in if the items are not used. Overstocking can impact the profitability of a business. This is because more stock is bought than being sold. Management of inventory to stock the correct quantity of items is essential to a company’s financial well-being. Overstocking also results in the buildup of obsolete stock. This is the material that has been bought or stocked in excess and is no longer in demand. In a manual system, this stock may be abandoned or forgotten. When it is in demand again, the company may buy more of it instead of using what is already stocked.

Understocking

Being understocked is also one of the inventory management problems. In manual systems, the flagging of materials that need to be reordered is dependent on the vigilance of the people managing inventory. When there is a slip-up, the company may find itself understocked to meet demand. In a supply chain, inventory management feeds the entire production process. Understocking can slow down production or even bring it to a halt. Not utilising the available warehouse space is also money wasted. Improper inventory management does not make the best use of all the available warehousing space that the company is paying for or bearing overheads on.

Lack Of trend forecasting

Trend forecasting is essential to managing a business. Projections and forecasts for inventory stocks are accurate when based on actual numbers and trends. Manual systems cannot quickly deliver summaries and reports. Inaccurate forecasting of trends could also lead to the company not anticipating seasonal rises and falls in demand. Lack of historical data to forecast trends is essential to avoid both overstocking and understocking.

Lack of centralization

Centralisation is not a problem in smaller businesses, with all their inventory stored in one location. As companies grow, they expand their inventory to different locations. Manual maintenance of inventory records makes it very difficult to communicate and access inventory data across locations. Manual reports and lists do not show the real-time stocks of inventory. Disconnected data is often a cause of delayed or incorrect shipping. It is also impossible for management to get an accurate real-time report on all their inventory across locations.

Improved visibility and transparency

Implementing an inventory management solution such as Tally helps you easily locate any item that is required. It also gives you complete data about the required item and its availability. Being able to locate inventory items improves the efficiency of the company. At the management level, the ability to visualize inventory helps in better decision making to streamline the process. Managers can easily visualise past trends and base their forecasts and planning on actual numbers.

Increased customer satisfaction

More transparency also allows the company to measure the efficiency of their inventory management. They can see how the stocks flow through the system and identify bottlenecks. In companies that ship to the customer directly from inventory, customer satisfaction based on shipping speeds can also be measured. Accuracy in identifying and shipping items will also enhance customer satisfaction.

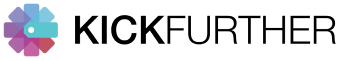

Stock analysis in TallyPrime

Increase in productivity

Inventory management software improves the efficiency and productivity of all the personnel involved in inventory management. Any inventory items can be easily found without having to search manually. Scaling up operations does not cause inventory management problems when you use an inventory management system. Computerised inventory management also lets you go paperless if you want to.

Accuracy in recording and tracking inventories

Management of stock through inventory management software reduces human error and provides accurate and up to date data. A computerised inventory management system such as Tally lets you know exactly where your inventory items are. Inventory data is updated and accurate in real-time.

Easy to manage and track inventories

When you use an inventory management system such as Tally, you have a better handle and control over the stock levels. You can easily track items that are being unnecessarily stockpiled. Even if you have obsolete inventory, it is tracked by the system to avoid buying more of what you already have.

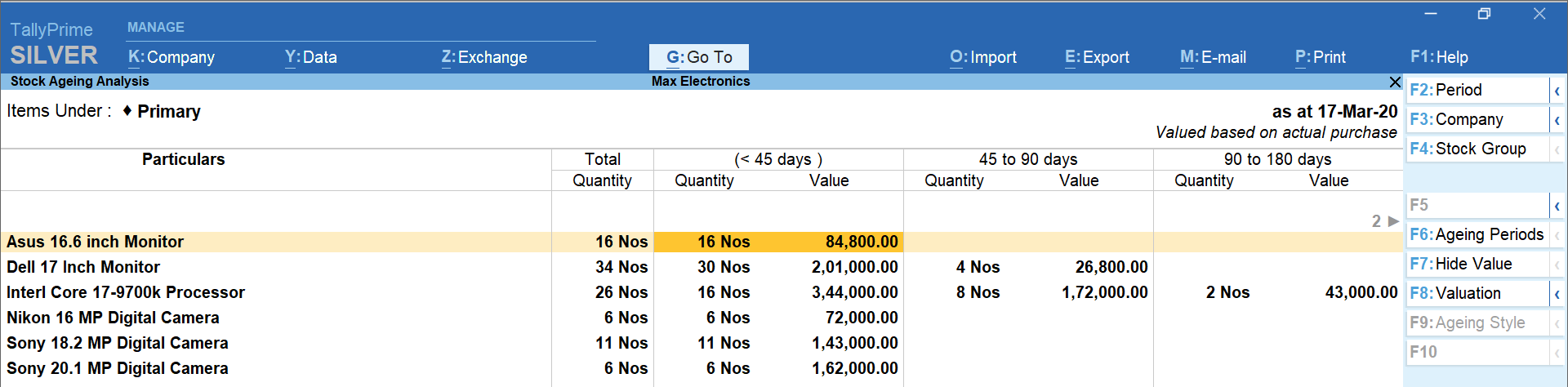

Get to know the fast-moving and high profitable inventories

When you can visualise and study the inventory movement and profit margins, it helps you identify fast moving items as well as items that fetch you a better profit margin.

Stock item-wise profitability analysis in TallyPrime

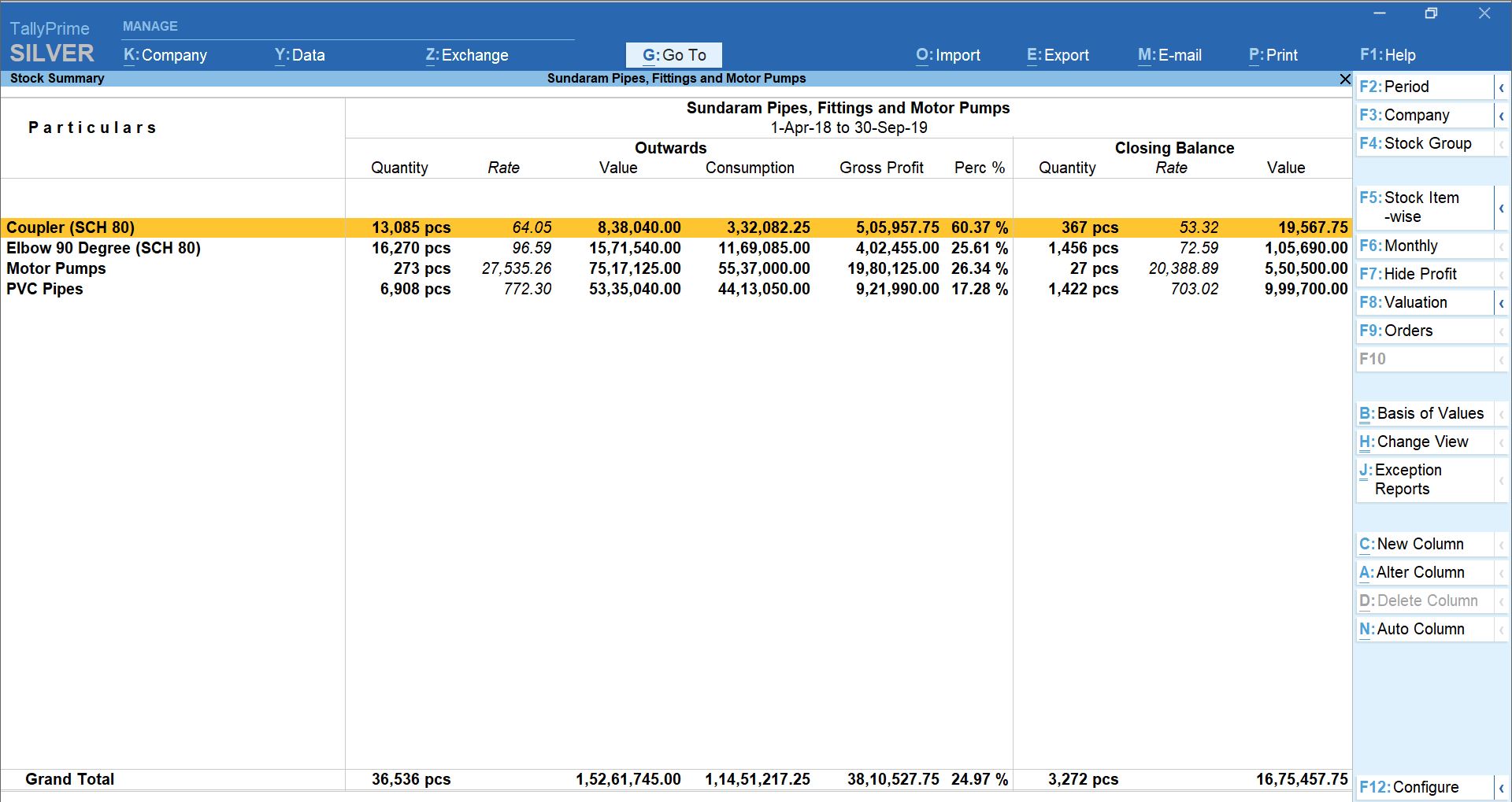

No worries of understocking and overstocking Of inventories

Inventory management shows you the items that are falling below the set reorder level. You can promptly order the required materials so that you do not fall short.

Reorder Levels On TallyPrime

Insights from reports help you in on-time business decisions

The easy access to reports that analyse inventory over time also empowers the company to better forecast trends and manage inventory accordingly. Decision making in the company becomes fact driven.

Connectivity and centralisation

Management of inventory through an integrated solution such as Tally helps in the centralisation of the inventory data. It also allows the inventory data to flow seamlessly between locations. So, the system is quick and efficient even when something has to be shipped out of inventory across locations. Tally also helps monitor inventory in different storage areas. Inventory can be easily managed across different warehouses within the same location or across geographies.

Cost optimization at all level of inventories

Inventory management through software such as Tally is also a good cost control measure. Efficient inventory management prevents mishaps such as overstocking that locks up precious capital. Software enhances the productivity of inventory management and warehouse personnel. Software also lets you use your warehousing space optimally. Empty and unused warehouse space is a waste of money that can be prevented by properly visualising and locating stock.

Help you get rid of the risk Of old And expired Stock

Goods that sit in inventory too long are a waste of money too! Efficient inventory management helps you attain that perfect balance of inventory to reduce costs and increase profits.

Switch to a smart integrated business solution with inventory management such as Tally to make the most of your inventory and warehousing processes. It will make a big difference to the efficiency, productivity and profitability of your business.

- Inventory Planning: Basic Concept and Benefits

- Inventory Management Techniques: Process and Tools with Example

Tally Solutions | Sep-23-2021

- Business Guides

- ERP Software

Latest Blogs

Moving to New Financial Year

How to Create and Use Barcodes for Inventory Management with TallyPrime

5 Inventory Management Best Practices

Warehouse Inventory Management – A Complete Guide

Multi-Location Inventory Management – A Definitive Guide

Saved Report Views: Enhancing Efficiency and Delight in TallyPrime Reports

Unlock business efficiency with TallyPrime - All-in one business management software!

Thanks for Applying

We will be in touch with you shortly.

Inventory Management Problems and Solutions

Inventory Management Unsolved Problems PDF Download

Previous Lesson: Inventory Valuation Problems

Next Lesson: Economic Order Quantity Problems

Problem # 1:

From the following calculate (i) Re-ordering Level and (ii) Minimum Level

Minimum usage 100 units per week Normal usage 200 units per week

Maximum usage 300 units per week Re-order period 4 to 6 weeks

(i) Re-ordering Level

Re-ordering level= Maximum consumption * Lead Time [maximum]

Re-ordering level= 300 * 6

Re-ordering level= 1,800 Units per week

(ii) Minimum Level

Minimum level= Reorder level – (Average consumption x lead time [Average])

Minimum level= 1,800 – (200 x 5)

Minimum level= 1,000 Units per week

>> Further Reading Inventory Management .

Problem # 2:

Calculate Ordering Level, Minimum Level and Maximum Level from the following data:

Re-order quantity 1,500 units Re-order period 4 to 6 weeks

Maximum consumption 400 units per week Average consumption 300 units per week

Minimum consumption 250 units per week

(i) Ordering Level

Ordering level= Maximum consumption * Lead Time [maximum]

Ordering level= 400 * 6

Ordering level= 2,400 Units per week

Minimum level= 2,400 – (300 x 5)

Minimum level= 900 Units per week

(iii) Maximum Level

Maximum stock level= Reorder level – (Min consumption * Lead time [minimum]) + EOQ

Maximum stock level= 900 – (250 * 4) + 1,500

Maximum stock level= 2,400 – (1,000) + 1,500

Maximum stock level= 2,900 Units per week

>> Further Reading Inventory Valuation .

Problem # 3:

The following information is available in respect of component DP 5:

Maximum stock level 8,400 units

Budgeted consumption- maximum 1,500 units per month

Budgeted consumption- minimum 800 units per month

Estimated delivery period Maximum 4 months and minimum 2 months

You are required to calculate Re-order level

Ordering Level

Ordering level= 1,500 * 4

Ordering level= 6,000 Units per week

>> Do Practice Inventory Valuation MCQ .

Problem # 4:

From the following date for the last twelve months, compute the Average Stock Level for a component.

Maximum usage in a month 300 units Minimum usage in a month 200 units

Average usage in a month 225 units Re-ordering quantity 750 units

Time lag procurement of material Maximum 6 months and Minimum 2 months

Average Stock Level

Average Stock Level = Minimum Stock Level + ½ of EOQ

Re-ordering level= 1,800 Units per month

Minimum level= 1,800 – (225 x 4)

Minimum level= 900 Units per month

Average Stock Level = 900 + ½ (750)

Average Stock Level = 1,275 Units per month

>> Practice Inventory Valuation Problems and Solutions .

Problem # 5:

Find out Minimum Stock Level, Maximum Stock Level and Ordering Level from the following particulars:

Minimum consumption 100 units per day Maximum consumption 175 units per day

Normal consumption 125 units per day Re-order quantity 1,500 units

Minimum period for receiving goods 7 days Maximum period for receiving goods 15 days

Normal period for receiving goods 10 days

(i) Ordering Level

Ordering level= 175 * 15

Ordering level= 2,625 Units per week

Minimum level= 2,625 – (125 x 10)

Minimum level= 1,375 Units per week

Maximum stock level= 2,625 – (100 * 7) + 1,500

Maximum stock level= 3,425 Units per week

>> Further Reading Cost of Goods Sold .

Related Topics

Inventory Management MCQs

Inventory Management

Economic Order Quantity

Economic Order Quantity MCQ

Economic Order Quantity Problems

More Interest

Payroll Systems

Labor Cost MCQs

Labor Cost Problems

Inventory Valuation

Further Readings

Cost Accounting

Cost Accounting MCQs

Cost Accounting Problems

Cost Accounting Papers

Cost Accounting Workbook

15 Comments

good article

Thanks for another excellent article. Where else could anyone get that kind of information in such a perfect way of writing?

fantastic article i like it god bless you

Thank you for some other wonderful article. Where else could anybody get that kind of information in such an ideal way of writing? I’ve a presentation subsequent week, and I’m on the look for such info.

This is my first time pay a quick visit at here and i am in fact pleassant to read everthing at single place.

You’re so cool! I do not suppose I’ve read anything like this before. So great to find somebody with a few original thoughts on this subject matter. Seriously.. thank you for starting this up. This site is something that is required on the web, someone with a little originality!

My relatives every time say that I am killing my time here at net, but I know I am getting knowledge daily by reading these good posts.

Way cool! Some very valid points! I appreciate you writing this article plus the rest of the website is really good.

Heya just wanted to give you a quick heads up and let you know a few of the pictures aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different web browsers and both show the same results.

I think the admin of this site is truly working hard in favor of his web site, as here every material is quality based data.

amazing article

Saved as a favorite, I really like your web site!

Hello everybody, here every person is sharing these familiarity, so it’s pleasant to read this web site, and I used to visit this web site every day.

Thanks for the article

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Submit Comment

6 Common Inventory Management Challenges and How to Solve Them

Inventory management is the process of overseeing the flow of goods and materials within an organization. It includes activities such as ordering, storing, tracking, and selling products, as well as ensuring that inventory levels are sufficient to meet customer demand without causing overstocking or stockouts. Effective inventory management is crucial for businesses to maximize profits by reducing carrying costs, minimizing waste, and avoiding lost sales due to out-of-stock items. It can be facilitated through the use of software systems, such as inventory management software. Also through the implementation of best practices, such as using demand forecasting and set reorder points.

Inventory Management Challenges

Companies can face many different challenges in inventory management. It is very important to fix these challenges to keep running the business. Tracking the purchase and sale of goods can help companies to grow their business effectively. FIFO and LIFO are the two types of inventory management, and companies may encounter varying issues with each approach that require specific strategies and unique solutions to overcome.

Data Inaccuracy

Data inaccuracy can be very bad for the company; it can literally destroy the business. Those companies that don’t track their stock regularly can face the problem of data inaccuracy. Data inaccuracy occurs due to different reasons such as; not tracking products, not removing damaged stock, employee theft, etc. If a company is not regularly checking its stocks and data, there is a possibility that employees of that company are stealing items. Most companies do inventory management once a year and they face such challenges. This issue can be fixed by changing the approach. Companies must do inventory management regularly and maintain records to avoid data inaccuracy.

Limited Visibility

Limited visibility can be a very big problem. The simple meaning of limited visibility is hard to find or not easily visible stock. Many companies have a big library of products in their warehouses, and franchises, and managing their stock can be very difficult. Such companies face the problem of limited visibility. This means the products are available, but the right location of the product is unknown. It is hard to find stock when companies are facing a limited visibility challenge. This can be fixed by categorizing the products and mentioning their locations in the records. For example; if a company is trying to find stock A and they don’t know where it is, it can waste a lot of time but if they have written down the location of stock A while unloading stock in a warehouse, that can make it easy to find the stock.

Manual Documentation

Many businesses no longer consider using books for manual documentation a reliable practice in inventory management. This is because relying on books can create challenges as they can easily become damaged, lost, or contain unreliable information, leading to errors in inventory data. Despite this, many companies continue to use manual documentation and face challenges as a result. A better approach is to use computer systems and software for inventory management and other business documentation. This approach allows for easy maintenance of records and enables backups to be taken, thus ensuring reliability and minimizing the risks of data loss.

Space Management

Effective space management is crucial for successful inventory management. Failure to manage space can cause chaos in the warehouse, stores, or franchises, making it difficult to locate and manage stock, ultimately disrupting the business. Using cardboard display boxes can help companies categorize and store products in an organized manner, making it easy to find items even in a large stock. These boxes are made of a strong, printable cardboard material that ensures product safety and allows brands to print stock-related details. This makes it easier for companies to manage their inventory and provide unique experiences to customers.

Poor Management of Stocks

Poor stock management can also be very disturbing in inventory management. If a company doesn’t plan stock management properly, it can be a very big problem. Stock management includes a bunch of different things such as; tracking in and out of products, reordering products, and high cost of storage. It is very important to track in and out of products and this can be done using inventory management software. Tracking in and out of products can help companies avoid financial losses. It has happened in many cases, companies have received faulty stock from manufacturers or wholesalers, and because they were not tracking in and out, they have to face financial loss.

When a company is tracking all products properly, reordering stock can become very easy. When a stock is reaching a dead end, the company can get to know about it through inventory management software and can reorder stock in time. The high cost of storage can also be an issue and this can be managed by using wholesale cardboard display boxes . These display boxes are made up of recycled material which costs less than any other material.

Expiry Management

Expiry management refers to the process of tracking and managing the expiration dates of products, materials, or documents. It involves monitoring the shelf life of perishable goods, the validity of contracts or licenses, and the expiration of important documents such as passports or visas. Effective expiry management is important for ensuring compliance with regulations, minimizing waste and financial losses, and maintaining customer satisfaction. It can be facilitated through the use of software systems, automated alerts, and regular inventory checks. If the software detects an expiry product, it can show a message with the product id.

* Terms & Conditions apply

In conclusion, inventory management can be a complex and challenging task for many businesses. In particular, those that deal with a large volume of products or operate across multiple locations. To address these challenges, businesses can implement a range of solutions, such as using inventory management software, improving supply chain visibility, setting reorder points, and implementing lean inventory management practices. By taking a proactive approach to inventory management, businesses can gain a competitive advantage and achieve sustainable growth.

My name is Sarah Allen. I am a professional writer, who loves to write about different topics. I take pride in my work, and even being very experienced in what I do, I am still eager to learn and serve.

Related Posts:

- 6 Common Electronics Assembly Manufacturing…

- Common Reasons for ERP Implementation Failures and…

- Order Fulfillment: Benefits and Common Challenges

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Inventory Management Example Problems with Solutions

Related Papers

sfgwerw uioyui