Free Shipping This Week!

📞 1-866-990-SKID (7543) Call Us!

1-866-990-7543 Give us a call!

- 3 Point Adapters

- Bale Handlers

- Bale Spears

- Box Graders

- Brooms & Sweepers

- Brush Cutters

- Cold Planers

- Concrete Equipment

- Concrete Mixers

- Concrete Pump

- Dozer Blades

- Feed Pusher

- Fence Installer

- Landscape Rake

- Log Splitters

- Manure Forks

- Over The Tire Tracks

- Pallet forks

- Planers & Graders

- Post Drivers

- Post & Tree Pullers

- Rotary Tillers

- Power Rakes

- Salt Spreaders

- Snow Blowers

- Snow Pushers

- Stump Grinders

- Trailer Mover

- Tree Shears

- Vibratory Rollers

- Winter Attachments

- Work Platforms

- Broom & Sweepers

- Concrete Breaker

- Concrete Mixer

- Forestry Claws

- Land Planers

- Mounting Plates

- Pallet Forks

- Snow Equipment

- Stump Grinder

- Trailer Movers

- Carpet Pole

- Concrete Hopper

- Fork Extensions

- Loading Box

- Mesh Handlers

- Skid Steer Adapter

- Spreader Bars

- Trash Hoppers

- Truss Boom & Jibs

- Compactor Plate

- Forestry Mulcher

- Grading Beam

- Post Driver

- Screening Buckets

- Tree Grubbers

- Part Finder

- Best Price Guarantee

- Shipping and Return Policy

What Is A Case Drain On A Skid Steer

- Article by Cohen Meyer

- October 25, 2021

A case drain is a specific component of a hydraulic system, its objective is to extend the life of a system and reduce time spent on repairs and maintenance. An unrestricted case-drain line is essential on a piston-type hydraulic motor, whether it has axial, radial or bent-axis design. Most skid steers rely on hydraulic systems to power their front loading arms.

Sometimes referred to as a ‘third line’, a case drain drains back the oil which has leaked past the primary seal, and in doing so, prevents pressure from building up against the outer seal. This oil is then returned to the tank or reservoir.

A case drain will have an in-line case drain filter to prevent contaminants from travelling from the hydraulic motor to the tank. Operating a skid steer without a case drain line could result in a full system failure as the shaft seal will be irreparably blown out, if not installed properly your hydraulic line will not work and in worst cases become damaged beyond repair.

A good case drain makes your hydraulic system more energy efficient and lowers the pressure on the tank, good general maintenance of your hydraulic system results in longer durability for your skid steer and attachments.

Read on if you want to understand more about hydraulics, skid steers, and the function of a case drain line and it’s filter.

What Are Case Drains Made From?

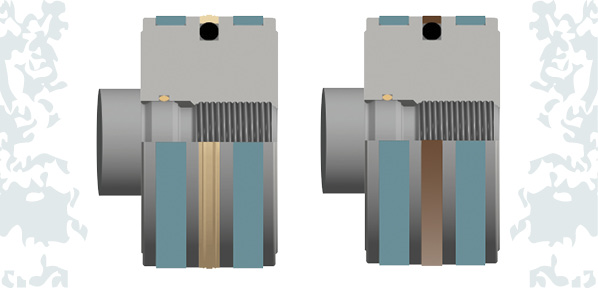

A case drain is made up of multiple elements whose materials vary, it’s important to know how to remove and disassemble the case drain in order to understand its function and materials. A case drain filter is contained within an aluminum canister.

To remove the filter make sure to plug the drain lines to avoid losing hydraulic fluid or introducing contamination into the system. Simply unscrew the hex nut to access the filter element.

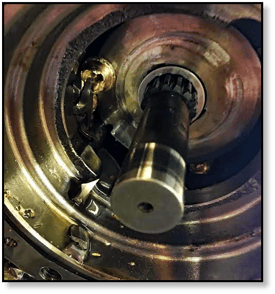

You may be surprised to find that case drain filters are made from a metal, sintered bronze to be specific. To the naked eye, the sintered bronze looks like one solid piece of metal but is actually thousands of bronze spheres that have been sintered together. Sintering is a heat treatment, like welding or soldering, that imparts strength and integrity to a ‘powdered’ material.

Sintering can determine a filter’s porosity which affects what goes through the filter and what doesn’t. Once sintered, the filter is now porous enough to allow hydraulic fluid to flow through it, yet remains dense enough to capture contaminants like metal and rubber debris which will eventually lead to a total system failure if left unmaintained.

When Should You Replace The Case Drain Filter?

Filters in a hydraulic system maintain fluid cleanliness at a level that maximizes component life. The appropriate cleanliness level is based on factors such as operating pressure and the internal clearances of components within a system.

If your case drain filter is blocked, then the hydraulic pressure of the motor will increase severely which will eventually lead to a myriad of mechanical and hydraulic issues and even a total system failure. Seals can be blown allowing hydraulic fluid and lubricant to leak out and also allowing contaminants to make their way into the skid steer and damage it irreparably.

If the filter in your case drain is no longer bronze in colour and looks mucky or dirty we suggest that you replace it. If your case drain is blocked then its worth dissembling the other filters and drain on the hydraulic system to ensure they have remained clean. It’s highly discouraged to attempt to clean your case drain or its filter.

Even if you had power tools or a heavy duty wire brush you will only move more trapped solids into the filter, clogging it even further. Case drain replacements are cheap when compared to replacing your whole final drive. Case drain maintenance is a key part of maintaining the life of your skid steer, and is often overlooked.

When Should A Case Drain Be Installed?

The main disadvantage of installing a filter on your hydraulics system is that back pressure created by the filter can cause total system failure caused by excessive pressure on the case drain if installed improperly

In some cases, case drains are considered optional. The case drain line is for low volume flow to the tank. In theory, by installing a high-pressure shaft seal and two check valves then internal leakage is technically drained into the return line, which is the usual function of a case line.

However, if reliability is what you are looking for then a case drain line is crucial for long term system maintenance.

It has generally been found that systems without case drains often result in failure due to shaft seal leaks. Case drain line installation can be tedious but will eradicate any problem relating to shaft seal leakage.

Oftentimes, if a vehicle doesn’t already have a case drain line fitted, the manufacturer will not necessarily outline the need for hydraulic fluid to be returned to the tank. If you want optimum reliability from your tank and hydraulics then fitting a case drain line is the way to go.

Closing Thoughts.

Case drain lines are a very specific component, its use is debated among hydraulics experts - some say you need a case drain and others suggest you don’t. Ultimately, understanding how a case drain works is fundamental to upholding your machines maintenance and making sure that your tools last for a long time.

Many system failures in hydraulics are caused by leaks from the tank. It’s important not to neglect your hydraulics system as it could put you, or your workers, at risk.

Once you know how case drain filters work and what their function is within the hydraulic system of a skid steer, then you can visit your mechanical professional and ask for their opinion on whether you need to install a case filter on your skid steer or not.

If you already have a case drain line but your tank is leaking, then you should get a mechanical professional to check if it needs to be replaced.

Written by Cohen Meyer

Leave a comment (all fields required)

Related blog posts.

Kubota SVL75 Attachments

Looking to take your Kubota SVL75 skid steer to the next level?

How Much Does A Concrete Pump Cost

In this article, we will answer all of these questions and provide you with some easy solutions for moving concrete at your job site.

Best Mini Excavator Mulcher

I will help you choose the best mini excavator mulcher in this article.

We want to make your shopping experience as simple as possible.

Contact Us Today to talk to one of our sales representatives!

Join Our Program

Sign Up For Free Give Aways and Promotions

Customer Service

Questions? (866)-315-3134 Se Habla Español

- Create an account

SALE PRICES & FREE SHIPPING (Lower 48 States Only) on select items. Ends April 15, 2024

What is a Case Drain on a Skid Steer? The Most Common Skid Steer Issues

Table of Content: 1. What are the most common skid steer problems? 2. What is a drain line and how important is It? 3. Clogged case drain filters 4. When should you replace the case drain filter? 5. Work with experts to keep your skid steer running

No matter how vigilant and careful we are with our equipment, it will at some point wear out. Maintenance is an unavoidable part of the life of every tool, especially heavy equipment, such as skid steers.

However, it is possible to keep the crucial parts in good condition for as long as possible. Today's article teaches us which parts are vital and what to pay attention to make sure your machine's great working condition.

What are the most common skid steer problems?

To start with, we will look at the most common problems that skid steer owners struggle with. The issues are connected to three strategic areas, such as skid steer’s engine, hydraulic system, and control system.

Engine problems

Most operators start to notice engine problems when the engine has difficulties starting properly. To start with, you should inspect the fuel system. Perform individual checks on all components, such as fuel filters, fuel lines, and the tank.

One of the most common causes of engine problems in diesel skid steers is infrequent changes of filters. It is also the case with machines that work in dusty environments. These require even more frequent filter changes.

Fuel tank issues include problems with the fuel flow to the injector from the tank. Such an occurrence decreases the engine’s operational ability. Improper flow may be caused by clogged fuel injector s, so checking them is the first action you should take if you suspect fuel tank malfunction.

Engine glow plugs in a skid steer are responsible for warming the engine’s combustion chambers in cold conditions. If they fail to do so, the engine cannot function properly. It can happen because of loosening glow plugs, so inspect whether they are tightly attached on both sides of the engine.

The engine’s throttle cable should be securely attached to the throttle body. Loose cables cause incorrect engine operation. Inspect both sides of the cable attached to the throttle body (usually on the motor’s top front).

Control system problems

Sometimes, the issue is closer than the operators think, which is the cabin of our skid steer. The lack of response to the directions given by the joystick causes a lot of frustration. It may be a sign of loose or disconnected steering connections. All you must do is tighten or connect them again.

Also, check the connection of the wires between the actuators, hydraulic pump, and the joystick. However, if all the above elements are properly connected and in good working condition, to resolve the issue you may need to install a new joystick control circuit board.

It is also advisable to check the safety switches on the skid steer, especially when the controls respond to your directions but slowly. Ensures a secured connection of the switches. It is also important to check whether there is a drain within the skid steer’s battery.

Hydraulic problems

The hydraulic system is one of the most important systems in your skid steer. Unfortunately, it is also one of the most problematic areas. With any signs of improper skid steer work, start by checking the level of the hydraulic fluid . The hydraulic systems work the most efficiently with a precise amount of fluid recommended by the equipment’s manufacturer. Therefore, ensure that the system is not underfilled or overfilled.

A clogged fuel filter i s often to blame when it comes to the skid steer's performance changes, especially the lack of power. It is because a clogged filter does not allow a free flow of fluid, and therefore affects the skid steer's power.

Another component worth inspecting is the pump. In the belt-driven model, improperly working pumps can cause loose belts and ultimately wear them, which decreases the hydraulic system’s performance.

The hydraulic lines are also worth inspecting, as they can be loose or have leaks. To properly inspect the lines, have the pump and engine running. Only then high pressure will ensure a quick leak identification. However, safety should always come first, so ensure using appropriate PPE , such as safety goggles and gloves. It is easier to incur injuries when working with high pressure.

The last important check you should perform is fittings , seals , and valves . Broken seals, loose fittings, and insufficiently open valves greatly affect the hydraulic system’s performance.

What is a drain line and how important is it?

A case drain line is a crucial element in a piston-type hydraulic motor. This component, also called a ‘third line’ drains back the oil which has leaked past the primary seal. Thanks to that, the pressure does not build up against the outer seal. The oil can then be returned to the tank.

Why is the case drain lines' presence important? Without a case drain line skid steer can be subjected to a full system failur e because of the shaft seal blow-out. Proper installation is the key to proper work of the hydraulic line and avoiding damaging it beyond repair. A case drain is accompanied by a case drain filter. Its function is to stop contaminants from getting to the tank from the hydraulic motor.

Clogged case drain filters

Replacing the case drain filter regularly is crucial for the proper functioning of your machine. Otherwise, the hydraulic fluid will not pass through, and there will be pressure build-up. It will happen even though it is a low-pressure line. Such high pressure will look for ways to escape and these ways will often use the weakest points in the system.

Usually, the weakest points in the drive motor system are the seals . They become prone to leakage which will speed up the process of key components deterioration. It comes because of insufficient lubrication and the generation of more contamination. Usually, systems without case drains often are subject to failures connected to shaft seal leaks.

High pressure can lead to the displacement of motor components . In the case of the axial piston final drive motor, the piston ball and shoes will be affected. The built-up tension can pull off the shoes and cause hard-to-repair damage . The pistons of a radial piston motor can be lifted off the cam and then forced back into it or lose contact altogether.

In extreme cases, the cover plate of your motor can even split and fly off at high speed! Not to mention that you might entirely lose control over your machine.

That is why replacing case drain filters with an appropriate frequency is necessary in maintaining your skid steer at optimal performance.

When should you replace the case drain filter?

Filters ensure fluid cleanliness which in turn maximizes the life of the system parts. The level of cleanliness depends on operating pressure and the internal clearances of components in the hydraulic system. Blocked case drain filter drastically increases the motor's hydraulic pressure, resulting in mechanical and hydraulic issues and leading to a total system failure.

If the color of your filter is dark and dirty instead of brown , it is high time you replaced your filter. If the case drain is blocked, you should disassemble the drain and remaining filters of the hydraulic system and check whether they have a proper cleanliness level.

Please, bear in mind that cleaning the filter or the case drain itself is not advisable. It usually results in further clogging of the filter and may lead to quicker damage to your final drive. Much as replacing the case drain and the filter is inexpensive, changing the entire final drive will be a lot more expensive.

Work with experts to keep your skid steer running

Case drain maintenance is a crucial part of maintaining the life of your machine. However, it is often overlooked. If your machine needs replacement of the case drain or any other component, browse our shop to find the right part .

If you have any questions regarding the state of your drain case filter or problems you experience with your skid steer, get in touch immediately. We are not only a supplier but, most of all, the experts in the field of skid steers.

What is a Backhoe and How to Use Backhoe Attachments?

What is a spreader bar used for and how to use it, pneumatic tires vs. solid tires. which tires are better for your skid steer, where are kubota tractors made a history of the kubota tractor company, what are the best skid steer tires for snow and mud, what is a flail mower choose the best flail mowers for compact tractors, how to maximize your tractor potential with 3-point attachments, new holland history. who owns new holland agriculture, how to start a snow removal business checklist.

What is a Case Drain Line ?

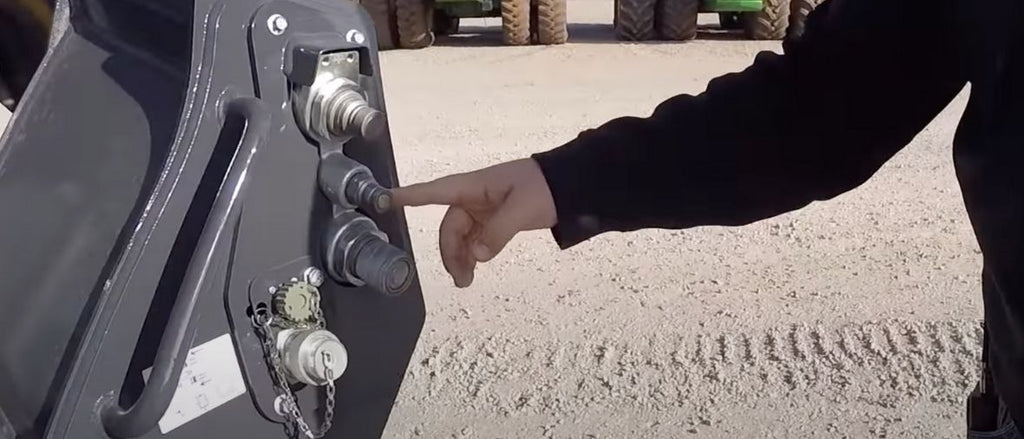

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain, that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line can also increase the efficiency of your hydraulic system as it will lower the back pressure on the tank line.

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

How Important is a case Drain Line ?

If we say having a case drain is critical and you operate without one, you will blow out your shaft seal. Be sure to check the motor sizing charts on our website.

Exception if you have a Hammer Valve

There is one exception in the need for a case drain on gear motors and that is if you excavator is equipped with a hammer valve, this is a larger free flow line back to tank.

Identifying your Case Drain Line

The following galleries show a highlighted case drain line on multiple skidsteer and excavator models.

Case Drain on Skidsteers

Case Drain on Excavators

- Auxiliary Electrical Connectors

- Boom Mowers – Skidsteer

- Boom Mowers – Tractor

- Brush Mulchers

- Excavator Mounting

- Feller Bunchers

- Flail Mowers

- Hydraulic Data - Flow & Pressure

- Hydraulic Motor Types

- Mini Skidsteers

- Price Lookup

- Product Lead Time

- PTO Power Packs

- Rotary Brush Cutter

- Screw Splitters

- Stump Grinders

- Stump planers

- Tile Drainage Plows

- Teeth Options

- Tree Puller

- Tree Shears

- Tree Spades

- Factory Discounts

- Corporate Contact

- Dealer Locator

- FIND YOUR FINAL DRIVE

- Eaton Hydraulic Motors

- Caterpillar

- New Holland

- Shop Talk Blog

- Request for Quote

- FINAL DRIVE SHOP

- Become Our Dealer

The Official Blog for Texas Final Drive

5 Common Hydraulic Motor Questions Answered

Final Drive , Final Drive Failure , Final Drive Motor Maintenance , Final Drive Motors , Final drives , Final Drive Maintenance

In this Shop Talk Blog post, we are going to discuss the answers to five very common questions about hydraulic motors: what is a case drain, how do hydraulic motors fail, what exactly is displacement, how are hydraulic motors rated, and how does a hydraulic motor differ from a final drive?

What is a hydraulic motor case drain?

The case drain line is a low pressure hydraulic line that runs from the final drive motor back to hydraulic fluid reservoir. Its purpose is to carry away excess internal leakage of hydraulic fluid from the final drive motor, a process known as case drain. Case drain is especially important on piston motors because, without that small amount of leakage, the pistons are functioning as metal on metal. Not all hydraulic motors have a case drain line, though. For those that do, it is important to regularly check and change the case drain filter. Damage from a clogged case drain filter can quickly run up hundreds or even thousands of dollars.

How do hydraulic motors typically fail?

There are several different causes of hydraulic motor failure . Here at Texas Final Drive, many of the catastrophic failures we see can be traced back to a failed seal that allowed fluids to leak out and damaging contaminants to make their way in. Another major source of problems is a clogged case drain filter . Issues with gear oil in the planetary hub (either it's low on gear oil or gear oil needs to be changed) are another major source of problems.

What is hydraulic motor displacement?

Displacement is the volume of fluid needed to turn the output shaft of the hydraulic motor by one full rotation. You will typically see displacement reported in cubic inches per revolution or cubic centimeters per revolution (keep in mind that 1 gallon is 231 cubic inches). Lets say that a hydraulic motor has a displacement of 16 cubic inches; that means that 16 cubic inches of fluid (about 0.07 gallons) of hydraulic fluid will need to be displaced to turn the motor one revolution.

How are hydraulic motors rated?

The key characteristics of hydraulic motors are displacement, pressure rating, torque , flow rate, and power. For a particular hydraulic motor, the displacement will be fixed or limited to a range, as in the case of a variable displacement motor. The pressure rating will also be fixed. The torque, flow rate, and power are related to these fixed characteristics.

How does a hydraulic motor differ from a final drive?

Some people may use the terms hydraulic motor and final drive interchangeably, but they aren't exactly the same. A final drive usually refers to a hydraulic motor that has a speed-reducing planetary gear system attached to it to increase the output torque.

We've only covered five of the most common questions about hydraulic motors. If you have any hydraulic motor questions, why not mention them in the comments? We'd love to hear what kind of topics you'd like to have addressed in future blog posts.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now .

Topics: Final Drive , Final Drive Failure , Final Drive Motor Maintenance , Final Drive Motors , Final drives , Final Drive Maintenance

Add a comment...

"shop talk blog" email updates, posts by topic.

- Heavy Equipment 101 (77)

- Excavators (66)

- Final Drive Maintenance (66)

- Final Drive (63)

- Mini-excavators (57)

- Hydraulic Motors (51)

- Final Drive Motors (46)

- Final Drive Failure (43)

- Skid Steers (34)

- Hydraulic Contamination (32)

- Maintenance (32)

- Final drive motor (30)

- Heavy Equipment (29)

- Hydraulic drive motor (28)

- Compact Track Loader (26)

- Skid-Steer Loaders (26)

- Gear oil (25)

- Reman Final Drives (25)

- Final Drive Motor Maintenance (23)

- hydraulic fluid (22)

- Preventative Maintenance (21)

- Final Drive Problem (20)

- Compact Excavators (19)

- Eaton Hydraulic Motors (17)

- Final Drive Motor Gears (17)

- Final Drive Diagnosis (14)

- Hydraulics (14)

- Troubleshooting (14)

- Contamination (13)

- Rebuilt Final Drive Motor (13)

- bearings (13)

- Case Drain Filters (12)

- Final Drive Motor Seals (12)

- Skid Loaders (12)

- Agriculture (11)

- Final drives (11)

- Heavy Equipment Safety (11)

- Construction (10)

- Hydraulic Pumps (10)

- Final Drive Motor Gearbox (9)

- Hydraulic Lines (9)

- Lubrication (9)

- Planetary Hub (9)

- bobcat final drive (9)

- Bobcat Equipment (8)

- Hydraulic Filters (8)

- Charge Pump (7)

- Compact Equipment (7)

- History (7)

- Undercarriage (7)

- Final Drive Installation (6)

- Final Drive Motor Assembly (6)

- Track Drives (6)

- Travel Motor (6)

- Eaton Hydraulic Pumps (5)

- Final Drive Motor Pumps (5)

- Hydrostatic Drive (5)

- Skidsteers (5)

- Used Equipment (5)

- forestry (5)

- rotator group (5)

- Aftermarket Final Drives (4)

- CAT Equipment (4)

- Case Drain (4)

- Duo-cone Seal (4)

- Eaton track drive motor (4)

- Final Drive Repair (4)

- Hydraulic System (4)

- Monster Machines (4)

- Multi Terrain Loader (4)

- hydraulic hoses (4)

- hydraulic ports (4)

- Autonomous Equipment (3)

- Autonomous Track Loader (3)

- Axial Piston Motors (3)

- Bobcat T190 (3)

- Bulldozer (3)

- Caterpillar (3)

- Fleet Management (3)

- ISO 4406 (3)

- John Deere (3)

- Komatsu (3)

- Predictive Maintenance (3)

- Radial Piston Motor (3)

- Tractor (3)

- core exchange (3)

- overheating (3)

- Bobcat 864 (2)

- Case Drain Flow (2)

- Christmas (2)

- Compact Utility Tractors (2)

- Crawler Tractor (2)

- Drive Sprocket (2)

- Fasteners (2)

- Filters (2)

- Final Drive Motor Technology (2)

- Geroler Motors (2)

- Hydraulic Fittings (2)

- Industry (2)

- Mining Truck (2)

- Motor Grader (2)

- New Holland (2)

- Pressure (2)

- Used Final Drive (2)

- Warranty (2)

- Water Contamination (2)

- Wheel motor (2)

- core buyback (2)

- hydraulic connections (2)

- machining (2)

- planetary flush (2)

- ASV Equipment (1)

- Air Contamination (1)

- Backhoe (1)

- Bonfiglioli (1)

- Bushing (1)

- CAT Parts (1)

- Cam ring (1)

- Case Equipment (1)

- Cavitation (1)

- Circlips (1)

- Compact Wheel Loader (1)

- Cotton Harvest (1)

- Covid-19 (1)

- Crawler Loader (1)

- Deconstruction (1)

- Demolition (1)

- Dinosaur (1)

- Disaster (1)

- Ditch Witch (1)

- Doosan Infracore (1)

- Drilling equipment (1)

- Dump truck (1)

- Dynapac (1)

- Efficiency (1)

- Electric (1)

- Excavator Buckets (1)

- Face Seal (1)

- Formulas (1)

- Front Loader (1)

- Gehl Equipment (1)

- Gerotor Motors (1)

- Gleaner Combines (1)

- Halloween (1)

- Hitachi (1)

- Hurricane Harvey (1)

- Hy-dash Final Drive (1)

- Hydraulic Shovel (1)

- Ingersoll Rand (1)

- Internal leakage (1)

- Kobelco (1)

- Loctite (1)

- Main Pump (1)

- Manufacturers (1)

- Materials (1)

- Military (1)

- Nabtesco (1)

- Nachi PHV (1)

- Oil Seal (1)

- Pump Rebuild (1)

- Quality (1)

- Reliability (1)

- Resources (1)

- Rexroth (1)

- Shipping (1)

- Spinning (1)

- Swash Plate (1)

- Swing Motor (1)

- Swivel Joint (1)

- Takeuchi (1)

- Terex Equipment (1)

- Terminology (1)

- Testing Final Drives (1)

- TimberPro (1)

- Underwater Excavators (1)

- Valve block (1)

- Wheel Loader (1)

- Wheeled Excavators (1)

- YouTube (1)

- bobcat 337 (1)

- bobcat e32 (1)

- bobcat e35 (1)

- core charge (1)

- drive shaft (1)

- hydraulic flush (1)

- hydraulic oil (1)

- kubota kx121 (1)

- kubota kx121-3 (1)

- lapping (1)

- main housing (1)

- pistons (1)

- seasonal (1)

- stripped drive shaft (1)

- turning (1)

- vibration (1)

Knowledge Base

Shop Talk Video

Identifying Final Drives

Final Drive Blank Spec Sheet

ONLINE MAINTENANCE SCHEDULES

CAT Planned Maintenance Schedules

Bobcat Maintenance Schedules

Bobcat CTL Maintenance Charts

Kubota Maintenance Schedules

INDUSTRIAL & CONSTRUCTION EQUIPMENT DATA

DiggerData.com

Equipment Trader

Ritchie Specs

- Recent Posts

- Top Industries

Agriculture

Construction

- Fiat Hitachi

- Fiat Kobelco

- Hanix / Nissan

- Ingersoll Rand

- Policies, Terms and Conditions

Texas Final Drive , a division of Woodland Fluid Power Inc 26639 Hufsmith Conroe Rd Magnolia, TX 77354 281-968-4773 or 281-259-5267

All manufacturers' names, symbols and descriptions are used for reference purposes only, and it is not implied that any part listed is the product of these manufacturers.

Request For Quote

© 2017 Texas Final Drive , a division of Woodland Fluid Power Inc – All Rights Reserved.

Fluid Power World

How to prevent case drain failure

By Mary Gannon | December 22, 2022

By Josh Cosford, Contributing Editor

Most variable displacement hydraulic pumps create and use internal leakage. The leakage is a function of the pump, designed from the factory to lubricate wear components, provide hydrostatic bearing pressure and offer pilot energy to critical functions like pressure compensators. Without controlled leakage, a variable pump would stop working at best and grenade itself at worst.

The internal leakage designed within pumps comes with a caveat — that leakage must exit the pump and do so at low pressure. The case is the “reservoir” for variable displacement piston and vane pumps. Because pumps need oil for lubrication, the non-business end of the pump where swashplates pivot or cam rings slide must also contain oil. The continuous flow of leakage oil keeps the case full and components lubricated, but the pressure will build inside the case without somewhere to exit.

You can’t simply redirect case fluid back to the suction port because that suction effect would drain the case entirely. Besides, case drain oil is essentially pure heat because, as we already know, any hydraulic energy lost before doing useful work is wasted as pure heat. In fact, case drain flow is a reflection of the inefficiency of a pump, even if some of that inefficiency is intentional. For example, a 90% efficient 10 gpm pump on standby will emit nearly 1 gpm of case drain flow (give or take, depending on volumetric efficiency).

A common trick to cool hydraulic power units involves running the case drain directly through an efficient oil-to-air cooler. By efficient, I mean not only thermally efficient but also flow efficiently. The hydraulic cooler must offer little to no backpressure to prevent excessive backpressure. Although case drains flow relatively little compared to pump flow, 10% of a 100 gpm pump is still 10 gpm, and plenty of small coolers cannot flow at that rate without significant back pressure.

You won’t expect manufacturers to list any more than 7-10 psi case drain pressure above inlet pressure. Should case pressure become excessive with too much drain backpressure or a clogged line, your best case scenario is a loss of power. The worst-case scenario is a reduction in the vital leakage flow required for lubricating all the pump’s critical components. Without that lubrication, a pump may last seconds before total failure. Just as bad with high case pressure is the lack of pressure compensator function — case pressure is additive to compensator spring pressure, and the pump will not come off stroke, causing internal damage.

Although the case drain tube or hose is typically the smallest pump line, it must never restrict case flow. Although coolers in the drain line are okay, you should avoid using filters, which may become clogged and create excessive back pressure. Although rare, occasionally, a drain line may become clogged with sludge. If you experience sludge or varnish elsewhere in your system, inspecting that case drain hose is a good idea.

Finally, be careful with case drain flow meters. Although properly sized units shouldn’t hurt, most flow meters use a spring-activated flow indicator that uses backpressure to identify flow rate. Should your pump start to ail, the added case flow may increase backpressure, thereby accelerating pump damage.

About The Author

Mary Gannon

Mary Gannon is editor of Fluid Power World. She has been a technical writer and editor for more than 13 years, having covered fluid power, motion control and interconnect technologies.

Search Fluid Power World

- Cylinders & Actuators

- Filtration/Contamination Control

- Fittings, Couplings & Adapters

- Fluid Conditioning

- Hose & Tubing

- Pumps & Motors

- Related Technologies

- Sensors & Gauges

- Valves & Manifolds

- Air Preparation & Regulation

- Compressed Air Technologies

- End Effectors & Grippers

- Engineering Basics

- Digital Issues

- Pnuematics Tech Toolbox

- Subscribe to Fluid Power World Print Magazine

- Webinars / Digital Events

- White Papers

- Women in Fluid Power

- Women in Engineering

- Design Guide Library

- Pneumatics Classroom

Brendan Casey's hydraulics blog

Hydraulicsupermarket.com – the source for how-to and money-saving information on hydraulics and pneumatics.

How to Use Case Drain Flow to Assess Hydraulic Pump or Motor Efficiency

“I tried one afternoon and evening to determine what was wrong with a hydrostatic transmission by monitoring case drain flow. I was confused by the readings I was seeing. There was a flow meter in the transmission pump outlet and another in its case drain that always showed charge pump flow, even though the motor was bypassing profusely. The motor case drain went through the transmission pump case to tank.”

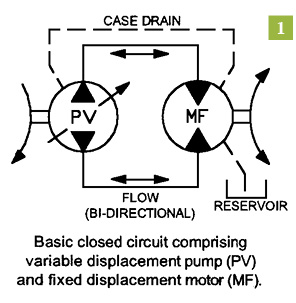

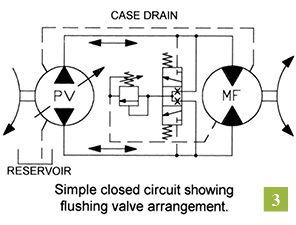

Recall that a hydrostatic transmission consists of a variable-displacement pump and a fixed or variable displacement motor, operating together in a closed circuit. In a closed circuit, fluid from the motor outlet flows directly to the pump inlet, without returning to the tank.

As well as being variable, the output of the transmission pump can be reversed, so that both the direction and speed of motor rotation are controlled from within the pump. This eliminates the need for directional and flow (speed) control valves in the circuit.

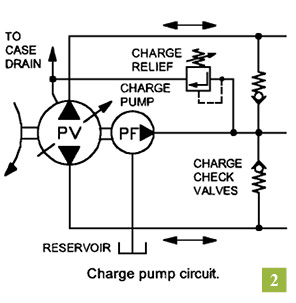

Because the pump and motor leak internally, which allows fluid to escape from the transmission circuit and drain back to tank, a fixed-displacement pump called a charge pump is used to ensure that the circuit remains full of fluid during normal operation. The charge pump is normally installed on the back of the transmission pump and has an output of at least 20% of the transmission pump’s output.

In practice, the charge pump not only keeps the transmission circuit full of fluid, it pressurizes it to between 110 and 360 PSI, depending on the transmission manufacturer. A simple charge pressure circuit comprises the charge pump, a relief valve and two check valves, through which the charge pump can replenish the transmission circuit. Once the circuit is charged to the pressure setting of the relief valve, the flow from the charge pump passes over the relief valve, through the case of the pump or motor or both, and back to tank.

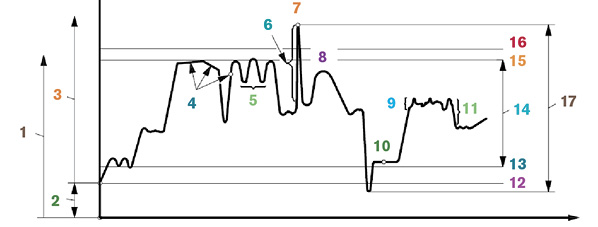

What is the significance of case drain flow?

When a pump or motor is worn or damaged, internal leakage increases and therefore the flow available to do useful work decreases. This means that the condition of a pump or motor can be determined by measuring the flow from its case drain line (internal leakage) and expressing it as a percentage of its theoretical or design flow.

When applying this technique to a hydrostatic transmission, charge pump flow must be considered. In most transmissions, the charge pump relief valve dumps into the case of either the pump or the motor. This means that in the circuit described by our reader, where the motor case drain flushed through the transmission pump case to tank, you would expect to see the flow meter in the transmission pump case drain line reading design charge pump flow. Here’s why:

Say charge pump flow was 10 GPM, of which 4 GPM was leaking out of the loop through the motor’s internals (case drain) and 2 GPM was leaking out of the loop through the pump’s internals. The balance of 4 GPM must therefore be going over the charge relief – but still ends up in either the pump or motor case, depending on the location of the relief valve. In this particular circuit, because the motor case drain flushed through the transmission pump case to tank, you would expect to see the flow meter in the transmission pump case drain line reading the sum of these three flows (10 GPM).

Before any meaningful conclusions can be drawn, the case in which the charge pump relief is dumping (motor or pump) must be determined and the two case drain lines (motor and pump) must be isolated from each other. If the charge relief dumps into the case of the pump, then it is possible to determine the condition of the motor by measuring its case drain flow, but not the pump. If the charge relief dumps into the case of the motor, then it is possible to determine the condition of the pump by measuring its case drain flow, but not the motor.

It is not possible to determine the condition of the component that has the charge relief valve dumping into it because there is no way of telling what proportion of the total case drain flow is due to internal leakage – unless of course the charge relief can be dumped externally while the test is conducted. While it is possible to do this on some transmissions, it’s not an easy or simple exercise.

Bottom line : using case drain flows to determine the condition of the components of a hydrostatic transmission, without thoroughly understanding the configuration of closed circuits, can result in incorrect conclusions and the costly change-out of serviceable components. And to discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get “Six Costly Mistakes Most Hydraulics Users Make… And How You Can Avoid Them!” available for FREE download here .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Engineering

- Hydraulics Repairs

- Pneumatics Repairs

- On Site Service

- Spray Tank Extensions

- Welding Equipment

- Hydraulic Components

- Pneumatic Components

- Supplier Links

Hydraulic Case Drain

Often in hydraulic systems, hydraulic motors and pumps run case drain hoses. The reason for this is to drain excess internal oil leakage from the motor. This is certainly critical in a piston motor and pump as the pistons have some internal leakage as they are actually just metal on metal. If no case drain hose is installed then the result will be, at the least, a blown shaft seal, and at worst, a split or damaged housing.

With gear pumps the leakage drains back into the suction hose internally, so no case drain is required. With gear motors and geroller/geroter motors, the oil can drain into the outlet port, however, that means that the oil pressure in the outlet port must not exceed the pressure rating of the seal. If it does, then a case drain needs to be installed. This will then usually mean you can run motors in series without damaging the motor.

Running a case drain can also assist with cooling, and also lubrication of the motors in some instances.

You must always check the manufacturer’s specification on maximum outlet and case pressures for correct installation.

How to Correctly Interpret Case Drain Flows in Hydrostatic Transmissions

When a pump or motor is worn or damaged, internal leakage increases and therefore the flow available to do useful work decreases. This means that the condition of a pump or motor can be determined by measuring the flow from its case-drain line (internal leakage) and expressing it as a percentage of its theoretical flow. However, using case drain flows to determine the condition of a hydrostatic transmission, without a thorough understanding of closed circuits, can lead to incorrect conclusions and the costly change-out of serviceable components.

Hydrostatic Transmission Basics

A hydrostatic transmission usually comprises a variable-displacement pump and a fixed or variable displacement motor, operating together in a closed circuit. In a closed circuit, fluid from the motor outlet flows directly to the pump inlet, without returning to the tank (Fig. 1).

Because the pump and motor leak internally, which allows fluid to escape from the transmission “loop” and drain back to tank, a fixed-displacement pump called a charge pump is used to ensure that the loop remains full of fluid during normal operation.

In practice, the charge pump not only keeps the loop full of fluid; it pressurizes it to between 110 and 360 psi, depending on the transmission manufacturer. A simple charge pressure circuit comprises the charge pump, a relief valve, and two check valves, through which the charge pump can replenish the transmission loop (Fig. 2). Once the loop is charged to the pressure setting of the charge relief valve, flow from the charge pump passes over the relief valve, through the case of the pump or motor or both, and back to tank.

A variation to this charge circuit arrangement is where the transmission is fitted with a purge valve (also called a transmission valve or replenishing valve or flushing valve). Because the fluid in a closed circuit flows directly from the motor outlet to the pump inlet, it means that apart from losses through internal leakage, the same fluid circulates continuously between pump and motor. If the transmission is heavily loaded, the fluid circulating in the transmission loop can overheat. The function of the purge valve is to positively exchange the fluid in the loop with that in the reservoir.

A purge valve is most effective when it is located at the motor, assuming the charge check valves (Fig. 2) are located in the transmission pump, as is the norm. The effect of this is that cool fluid drawn from the reservoir by the charge pump charges the low-pressure side of the loop through the check valve located close to the transmission pump inlet. The volume of hot fluid leaving the motor outlet that is not required to maintain charge pressure in the low pressure side of the loop vents across the purge valve relief into the case of the motor and back to tank—sometimes via the transmission pump case.

Drain-Line Gymnastics

This arrangement is important to keep in mind when using case drain flow to determine the condition of a hydrostatic transmission because charge pump flow must be taken into account. Consider an example where charge pump flow is 10 gpm, of which 4 gpm is leaking out of the loop through the motor’s internals (case drain) and 2 gpm is leaking out of the loop through the pump’s internals. The balance of 4 gpm must therefore be going over either the charge or purge relief valve—but still ends up in the pump or motor case, depending on the location of these valves.

In other words, it is not possible to determine the condition of the component that has the charge or purge relief valve dumping into it because there is no way of telling what proportion of the total case drain flow is due to internal leakage—unless the relief valve can be vented externally while the test is conducted.

When conducting these tests, it is also important to understand that the volume of internal leakage from a hydrostatic transmission cannot exceed the flow rate of its charge pump. Consider for a moment, a transmission that has a volumetric efficiency of 100%, that is, the pump and motor have no internal leakage. The transmission loop has a total volume of two gallons and is full of fluid. Because there is no internal leakage, there is no need for a charge pump.

When the pump is stroked to maximum displacement, this circulates the two gallons of fluid in the loop at a rate of, let’s say, 50 gpm. Because it’s a closed loop, with no leakage, the flow from pump to motor is 50 gpm and the flow from motor to pump is 50 gpm.

Now let’s introduce internal leakage of 0.5 gpm in each of the pump and motor. The result is that, with no charge pump, after one minute there will only be one gallon of fluid left in the loop (the other gallon will have leaked back to tank). However, within a second of the transmission starting to leak, the transmission pump will start to cavitate and the severity of this cavitation will increase with each passing second until the transmission destroys itself.

If a charge pump with a flow rate of 1 gpm is installed in the circuit, the problem is solved, temporarily at least. With 1 gpm leaking out of the loop and 1 gpm being replenished by the charge pump, the status quo is maintained—until wear causes the internal leakage of the transmission pump and/or motor to exceed 1 gpm.

As you can see, it’s not possible for the internal leakage of a hydrostatic transmission to exceed the flow rate of its charge pump. Charge pump flow rate is typically 20% of transmission pump flow rate. This means that volumetric efficiency can drop to 80% before the transmission will start to cavitate and ultimately destroy itself. The trick is to overhaul the transmission before this point is reached!

About the Author: Brendan Casey is the founder of HydraulicSupermarket.com and the author of Insider Secrets to Hydraulics, Preventing Hydraulic Failures, Hydraulics Made Easy and Advanced Hydraulic Control . A fluid power specialist with an MBA, he has more than 20 years experience in the design, maintenance and repair of mobile and industrial hydraulic equipment. Visit his website: www.HydraulicSupermarket.com.

- brendan casey

- case drain flow

- hydrostatic

- transmission

Share this information.

Related posts.

Fluid Power Vocabulary ISO 5598

The Top Three Reasons Cylinders Fail

2021 Systems Integrator Directory Listing

Pneumatic Devices Meet the Challenges of Dairy Processing

Innovative Design at Aerospace Saves 86%

Monitoring Hydraulic Pump Case Drain: Yes or No

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Get Our Enews!

Fluid Power Journal Resources

- Sign Up for our E-Newsletter

- Videos Featuring Hydraulics & Pneumatics

- Download Industry Whitepapers

- Watts It All About

- Targeted Display Advertising

- Corporate Headquarters

- Cleveland, Ohio

- Atlanta, Georgia

- Dallas, Texas

- Houston, Texas

- Seattle, Washington

- Los Angeles, California

- Birmingham, UK

- Shanghai, China

- Cleveland, USA

- Toronto, Canada

- Nottingham, UK

- Xuzhou, China

- Ningbo, China

- Making Connections

- Our History

- Fittings 101

- Industry Insights

- Downloading CAD

- Finding Parts

- Essential Tube Fittings Content

- Essential Aerospace Content

- Essential Instrumentation Content

- Essential International Adapters Content

- Pressure Ratings

- Cross Reference

- View All Categories

- Rhino by Brennan

- Tube Fittings and Adapters

- Flange Fittings

- DIN Fittings

- Conversion Adapters

- O-Ring Face Seal Fittings

- Double Ferrule Tube Fittings

- Single Ferrule Tube Fittings

- Instrumentation Valves

- Single Ferrule Tube Fittings – Brass

- Double Ferrule Tube Fittings – Brass

- Flareless Bite Type

- Flare-O Fittings

- Brass Fittings

- O-Rings and Seals

- Test Point Fittings

- Push to Connect PCNY

- Push to Connect PCNB

- Push to Connect PCDT-B

- Push to Connect PCDT

- Accessories

Brennan Blog

Drain lines, valves, filters, lines and pumps in a hydraulic system.

Ally Pulskamp

Sizing case drain lines . Typically, hydraulic motors and pumps have hoses that run to a case drain in order to drain excess internal oil from the motor. Having a case drain usually requires running motors in series to avoid damage. If the case drain line is undersized on a hydraulic pump ( piston), it can cause the pressure in the case to be too high. As the pump’s life depreciates, its volumetric efficiency will decrease, which in turn will increase leakage from the case drain line. If there is extreme case pressure, it can cause the piston shoe to lift off of the swash plate. This will cause damage that will force the pump to stop working. Go by the case drain port size or up-size it. It is important to make sure the case pressure is below the max rating, which, if necessary, can be adjusted at the case drain port size, or increase the size of the port. Case pressure can also become too high at:

- The reservoir well above the pump

- The pressurized tank

- A temperature that is too low for the viscosity of the oil being used

- A viscosity that is too low for the operating temperature

Alleviate pump failure by mitigating caveated or aerated components. If air is allowed to enter the system, the aeration will produce erosive damage when passing through the pump. In addition, cavitation can cause insufficient pump inlet, which can damage the pump. Either of these conditions can be very destructive.

- Aeration is caused by air entering the pump inlet and mixing with the fluid. Low pump pressure at the inlet will cause air bubbles to expand and, as the aerated fluid reaches the pressure side of the pump, the bubbles will disintegrate and implode which causes internal erosion of the system.

- Similar to aeration, extreme vacuum in a component will cause cavitation, which allows vapor bubbles to form in the fluid, ultimately damaging the pump.

Either of these conditions will cause pump noise to go up. If the system is allowed to continue to operate the pump will eventually fail. To safeguard against this problem in the design phase any source of air must be contained and the potential of vacuum at the inlet must be alleviated.

It’s important to design for flow amplification when sizing filters, lines and valves

If the proper size of the lines is not selected to handle a higher flow rate, unwanted heat will occur causing damage to motors or other hydraulic system components. When designing a hydraulic system valves must be selected and sized correctly, or flow will be restricted which can cause it to unseat. In addition, the filter must be sized correctly, or the bypass valve may open causing some of the fluid to be unfiltered or cause a flow surge that could collapse the element.

The control of pressure in a system is paramount in the design. Within hydraulic system components and their functions, pressure control valves are essential in preventing leaks or bursting of pipes, hoses or tubing. This is largely dependent on the proper selection of pressure control valves, which may include:

This blog is an excerpt from our whitepaper, Hydraulic Safety Begins With the Design. Click here or the link below to download your free whitepaper!

Primary Sources Include

- Grading & Excavation Contractor

- Hydraulics & Pneumatics 1

- Hydraulics & Pneumatics 2

- Machinery Lubrication

- Society of Tribologists and Lubrication Engineers

- Swedish Institute of Standards

- Fittings (54)

- Company Updates (45)

- Aerospace (26)

- Hydraulic Maintenance (23)

- Instrumentation (18)

- Helpful Info (14)

- Industry News (14)

- Supply Chain (14)

- Tradeshows (13)

- Distributed Manufacturing (11)

- Flange Fittings (11)

- Hose Fittings (10)

- Push To Connect (10)

- Hydraulic Safety (9)

- Technology (9)

- Tube Fittings (9)

- O-Ring Face Seal Fittings (6)

- Thread Identification & Measurement (6)

- Value Through Strength (5)

- Announcements (4)

- Distributors (4)

- Fragmentation (4)

- Literature (4)

- Specialty Alloys (4)

- Acquisitions (3)

- Forged Fittings (3)

- Giving Back (3)

- Agriculture (2)

- Brennan Value (2)

- Contamination (2)

- Brennan University (1)

- Crimp Oil (1)

- Industrial Marketing (1)

- Oil and Gas (1)

- Truck and Trailer (1)

Recent Posts

Subscribe to blog notifications.

Keep up to date with the latest from the Brennan Blog by subscribing to blog notifications below. Every month we will send you a brief digest of the latest posts with a link where you can read more.

Share this Post!

Share this post on social networks using the icons below.

Distribution & Sales

Walsall, West Midlands

Manufacturing Nottingham, Nottinghamshire Head Office: Cleveland, Ohio

USA: Atalanta, Georgia Dallas, Texas Houston, Texas Seattle, Washington Los Angeles, California Canada: Toronto, HQ Vancouver Calgary Montreal Winnipeg China: Shanghai Ningbo Yuhan Xuzhou

Distribution & Sales: (+44)1922 650 039 Manufacturing: (+44)115 968 1163

Privacy Policy

Search Entire Site

© Brennan Industries 2023

- Search Search for:

most case drains specify3 psi or less

- Subscribe Today!

- Current Issue

- GearTalk Podcast

- Unboxing Videos

- Machinery Lubrication Level 1

- Machinery Lubrication Level 2

- Oil Analysis Level 2

- Oil Analysis Level 3

- Machinery Lubrication Engineering

- Online Training

- International Training

- Machinery Lubrication Conference

- Reliable Plant Conference

- Buyer's Guide

Case Drain Leakage From Hydrostatic Transmissions

When a pump or motor is worn or damaged, internal leakage increases and therefore the flow available to do useful work decreases. This means that the condition of a pump or motor can be determined by measuring the flow from its case drain line (internal leakage) and expressing it as a percentage of its theoretical or design flow.

However, using case drain flows to determine the condition of a hydrostatic transmission, without a thorough understanding of closed circuits, can lead to incorrect conclusions and the costly change-out of serviceable components.

What is a Hydrostatic Transmission?

A hydrostatic transmission consists of a variable-displacement pump and a fixed or variable displacement motor, operating together in a closed circuit. In a closed circuit, fluid from the motor outlet flows directly to the pump inlet, without returning to the tank (Figure 1).

As well as being variable, the output of the transmission pump can be reversed, so that both the direction and speed of motor rotation are controlled from within the pump. This eliminates the need for directional and flow (speed) control valves in the circuit.

Because the pump and motor leak internally, which allows fluid to escape from the loop and drain back to the tank, a fixed-displacement pump called a charge pump is used to ensure that the loop remains full of fluid during normal operation.

In practice, the charge pump not only keeps the loop full of fluid, but it also pressurizes the loop to between 110 and 360 PSI, depending on the transmission manufacturer. A simple charge pressure circuit comprises the charge pump, a relief valve and two check valves, through which the charge pump can replenish the transmission loop (Figure 2).

Once the loop is charged to the pressure setting of the relief valve, the flow from the charge pump passes over the charge relief valve, through the case of the pump or motor or both, and back to the tank.

A variation to this arrangement is where the transmission is fitted with a flushing valve (also called a transmission valve or replenishing valve). Because the fluid in a closed circuit flows directly from the motor outlet to the pump inlet, it means that apart from losses through internal leakage, the same fluid circulates continuously between pump and motor.

If the transmission is heavily loaded, the fluid circulating in the loop can overheat. The function of the flushing valve is to positively exchange the fluid in the loop with that in the reservoir.

A closed circuit flushing valve usually comprises a pilot-operated directional valve and a low-pressure relief valve (Figure 3).

When the transmission is in neutral, the directional valve is centered and the gallery to the low-pressure relief valve is blocked. In this state, the flushing valve has no function and the charge relief valve in the transmission pump (Figure 2) regulates charge pressure.

When the transmission is operated in forward or reverse, the high-pressure side of the loop pilots the directional valve. This opens the low-pressure side of the loop to the flushing relief valve gallery. This relief valve is set around 30 PSI lower than the charge relief valve and therefore it regulates charge pressure when the transmission is operating in forward or reverse.

A flushing valve is most effective when it is located at the motor, assuming the charge check valves (Figure 2) are located in the transmission pump, as is the norm. The effect of this is that cool fluid drawn from the reservoir by the charge pump, charges the low-pressure side of the loop through the check valve located close to the transmission pump inlet.

The volume of hot fluid leaving the motor outlet that is not required to maintain charge pressure in the low-pressure side of the loop, vents across the flushing valve relief into the case of the motor and back to the tank, usually via the pump case.

When using case drain flow to determine the condition of a hydrostatic transmission, charge pump flow must be taken into account. Consider an example where charge pump flow is 10 gallons per minute (GPM), of which 4 GPM are leaking out of the loop through the motor’s internals (case drain) and 2 GPM are leaking out of the loop through the pump’s internals. The balance of 4 GPM must therefore be going over either the charge or flushing valve relief - but still ends up in the pump or motor case, depending on the location of this valve.

Before any meaningful conclusions can be drawn, the case in which the charge or flushing valve relief is venting (motor or pump) must be determined and if connected, the two case drain lines must be isolated from each other.

If the charge or flushing valve relief vents into the case of the pump, then it is possible to determine the condition of the motor by measuring its case drain flow, but not the pump. If the charge or flushing valve relief vents into the case of the motor, then it is possible to determine the condition of the pump by measuring its case drain flow, but not the motor.

It is not possible to determine the condition of the component that has the charge or flushing valve relief venting into it because there is no way to determine what proportion of the total case drain flow is due to internal leakage - unless the relief valve can be vented externally while the test is conducted.

When conducting these tests, it is important to understand that the volume of internal leakage from a hydrostatic transmission cannot exceed the flow rate of its charge pump. Consider a transmission that has a volumetric efficiency of 100 percent, that is, the pump and motor have no internal leakage. The transmission loop has a total volume of two gallons and is full of fluid. Because there is no internal leakage there is no need for a charge pump.

The pump is stroked to maximum displacement, which circulates the two gallons of fluid in the loop at a rate of 50 GPM. Because it’s a closed loop, with no leakage, the flow from pump to motor is 50 GPM and the flow from motor to pump is 50 GPM.

Now introduce internal leakage of 0.5 GPM in both pump and motor. The result is that with no charge pump, after one minute only one gallon of fluid will remain in the loop (the other gallon will have leaked back to the tank). However, within a second of the transmission starting to leak, the transmission pump will start to cavitate and the severity of this cavitation will increase with each passing second until the transmission destroys itself.

If a charge pump with a flow rate of 1 GPM is installed in the circuit, the problem is solved, at least temporarily. With 1 GPM leaking out of the loop and 1 GPM being replenished by the charge pump, the status quo is maintained until wear causes the internal leakage of the transmission to exceed 1 GPM.

As you can see, it’s not possible for the internal leakage of a hydrostatic transmission to exceed the flow rate of its charge pump. Charge pump flow rate is typically 20 percent of transmission pump flow rate. This means that volumetric efficiency can drop to 80 percent before the transmission will cavitate and destroy itself. The trick is to overhaul the transmission before this point is reached.

- Get Solutions By Phone 866.966.2538

- Order Status

- Rewards Program

- Newsletter Sign Up

Stay attached

Price Match Guarantee

Direct Shipping

Hassle-Free Returns

Expert Service

Financing Available

Connect with us.

Hydraulic Flat Faced Coupler Male | Case Drain

See more by skid steer solutions.

A surcharge of $ is included to off-set the rising costs of steel | Learn more

Built To Order

Check your machine specs, your machine specs.

Max Pressure

Lift Capacity

- Create New Wish List

STEEL PRICES RISE:

The carbon steel market is poised to grow by 699.35 MT during 2020-2024 progressing at a CAGR of almost 8% during the forecast period." (Source: Business Wire)

This is what we are seeing all across the industry; day after day new emails from vendor's telling us that their prices are rising, every order we make for materials needs to be revised because the last price is no longer valid, and for good reason. The cost of steel materials has been steadily increasing throughout 2020, and it unfortunately has not slowed into 2021. The reduced capacities of companies in this industry due to Covid-19 health and safety regulations continues to have an impact. As a result, we are forced to increase our list pricing for 2021 and add a steel surcharge to off-set the rising costs that is projected to continue this year. We apologize for any inconvenience this may have on our close and prospective customers. We we will do what we can to keep our prices low when the opportunities are found, but right now we are left with little options.

Thank you for your understanding and continued support.

JORDEN LEIB, VICE PRESIDENT OF SKID STEER SOLUTIONS

Product overview, skid steer male hydraulic quick connect couplers | case drain 3/8" to 1/2" npt.

Utilize Hydraulic Case Drain on your machine to avoid damage to your machine and attachments when applicable. Avoid blown seals or damaged housings. Case Drains can also assist with cooling.

These case drain units are 3/8" to 1/2" NPT thread.

Price includes one male unit.

Order with confidence knowing that these units are the preferred models of all operators at Skid Steer Solutions, and utilized in many Eterra Attachments as well.

Specifications

Featured video.

Skid Steer Hydraulic Couplers Sizing and Overview

Couplers are essential for any operator looking to power an at...

Skid Steer Solutions Quick Tips: Keep Your Hydraulic Couplers Out Of Harms Way

Compatible parts, customer reviews, knowledge base, helpful articles, recently viewed products.

- Search Menu

- Volume 2024, Issue 4, April 2024 (In Progress)

- Volume 2024, Issue 3, March 2024

- Bariatric Surgery

- Breast Surgery

- Cardiothoracic Surgery

- Colorectal Surgery

- Colorectal Surgery, Upper GI Surgery

- Gynaecology

- Hepatobiliary Surgery

- Interventional Radiology

- Neurosurgery

- Ophthalmology

- Oral and Maxillofacial Surgery

- Otorhinolaryngology - Head & Neck Surgery

- Paediatric Surgery

- Plastic Surgery

- Transplant Surgery

- Trauma & Orthopaedic Surgery

- Upper GI Surgery

- Vascular Surgery

- Author Guidelines

- Submission Site

- Open Access

- Reasons to Submit

- About Journal of Surgical Case Reports

- Editorial Board

- Advertising and Corporate Services

- Journals Career Network

- Self-Archiving Policy

- Journals on Oxford Academic

- Books on Oxford Academic

Article Contents

- Introduction

- Acknowledgements

- Conflict of interest statement

- Financial disclosure

- < Previous

A new simple and innovative technique for surgical drains fixation

- Article contents

- Figures & tables

- Supplementary Data

Abeer Alsherawi, Fatima Saoud Al-Mohannadi, Mohamed Badie Ahmed, A new simple and innovative technique for surgical drains fixation, Journal of Surgical Case Reports , Volume 2023, Issue 12, December 2023, rjad687, https://doi.org/10.1093/jscr/rjad687

- Permissions Icon Permissions

Seroma is a common complication post many plastic surgery procedures. To overcome this issue, drain insertion became a standard of care in many procedures. Existing methods for fixing the drain like the Roman sandal, purse string, and mesentery have limitations, including loosening and skin problems. A new, innovative, and efficient drain fixation technique is introduced in this paper. It involves using silk or similar non-absorbable sutures in a simple five-step process. This method ensures secure drain placement without undesirable outcomes. It avoids the need to force a knot over the skin, reducing the risk of skin damage or necrosis. In conclusion, the study introduces a straightforward, safe, and effective drain fixation method, reducing risks associated with fluid accumulation after surgery.

- surgical procedures, operative

- plastic surgery procedures

- risk reduction

- wound seroma

- standard of care

- surgical drains

Email alerts

Citing articles via, affiliations.

- Online ISSN 2042-8812

- Copyright © 2024 Oxford University Press and JSCR Publishing Ltd

- About Oxford Academic

- Publish journals with us

- University press partners

- What we publish

- New features

- Open access

- Institutional account management

- Rights and permissions

- Get help with access

- Accessibility

- Advertising

- Media enquiries

- Oxford University Press

- Oxford Languages

- University of Oxford

Oxford University Press is a department of the University of Oxford. It furthers the University's objective of excellence in research, scholarship, and education by publishing worldwide

- Copyright © 2024 Oxford University Press

- Cookie settings

- Cookie policy

- Privacy policy

- Legal notice

This Feature Is Available To Subscribers Only

Sign In or Create an Account

This PDF is available to Subscribers Only

For full access to this pdf, sign in to an existing account, or purchase an annual subscription.

- Share full article

For more audio journalism and storytelling, download New York Times Audio , a new iOS app available for news subscribers.

Israel’s Deadly Airstrike on the World Central Kitchen

The story behind the pioneering aid group and how it mistakenly came under attack..

From “The New York Times,” I’m Michael Barbaro. This is “The Daily.”

The Israeli airstrike that killed seven aid workers delivering food in Gaza has touched off outrage and condemnations from across the world. Today, Kim Severson on the pioneering relief crew at the center of the story, and Adam Rasgon on what we’re learning about the deadly attack on the group’s workers. It’s Thursday, April 4.

Kim, can you tell us about the World Central Kitchen?

World Central Kitchen started as a little idea in Chef José Andrés’ head. He was in Haiti with some other folks, trying to do earthquake relief in 2010. And his idea at that point was to teach Haitians to cook and to use solar stoves and ways for people to feed themselves, because the infrastructure was gone.

And he was cooking with some Haitians in one of the camps, and they were showing him how to cook beans the Haitian way. You sort of smash them and make them a little creamy. And it occurred to him that there was something so comforting for those folks to eat food that was from their culture that tasted good to them. You know, if you’re having a really hard time, what makes you feel good is comfort food, right? And warm comfort food.

So that moment in the camp really was the seed of this idea. It planted this notion in José Andrés’ mind, and that notion eventually became World Central Kitchen.

And for those who don’t know, Kim, who exactly is Chef José Andrés?

José Andrés is a Spanish chef who cooked under some of the Spanish molecular gastronomy greats, came to America, really made his bones in Washington, DC, with some avant-garde food, but also started to expand and cook tapas, cook Mexican food. He’s got about 40 restaurants now.

Yeah. And he’s got a great Spanish restaurant in New York. He’s got restaurants in DC, restaurants in Miami.

Come with me to the kitchen. Don’t be shy.

He’s also become a big TV personality.

Chef, are you going to put the lobster in the pot with the potatoes?

We’re going to leave the potatoes in.

Leave the potatoes in!

He’s one of the most charismatic people I’ve ever been around in the food world.

He’s very much the touchstone of what people want their celebrity chefs to be.

So how does he go from being all those things you just described, to being on the ground, making local comfort food for Haitians? And how does this all go from an idea that that would be a good idea, to this much bigger, full-fledged humanitarian organization?

So he started to realize that giving people food in disaster zones was a thing that was really powerful. He helped feed people after Hurricane Sandy, and he realized that he could get local chefs who all wanted to help and somehow harness that power. But the idea really became set when he went to Houston in 2017 to help after Hurricane Harvey.

And that’s when he saw that getting local chefs to tap into their resources, borrowing kitchens, using ingredients that chefs might have had on hand or are spoiling in the fridge because the power is out and all these restaurants needed something to do with all this food before it rotted — harnessing all that and putting it together and giving people well-cooked, delicious — at least as delicious as it can be in a disaster zone — that’s when World Central Kitchen as we know it today sort of emerged as a fully formed concept.

The first pictures now coming in from Puerto Rico after taking a direct hit — Hurricane Maria slamming into the island. And as you heard, one official saying the island is destroyed.

Shortly after that, he flew to Puerto Rico, where Hurricane Maria had pretty much left the entire island without water and in darkness.

He flew in on one of the first commercial jets that went back in. He got a couple of his chef buddies whose kitchens were closed, and they just decided to start cooking. They were basically just serving pots of stew, chicken stew, in front of the restaurants.

The lines got longer. And of course, chefs are a really specific kind of creature. They really like to help their community. They’re really about feeding people.

So all the people who were chefs or cooks on the ground in Puerto Rico who could wanted to help. And you had all these chefs in the States who wanted to fly down and help if they could, too. So you had this constant flow of chefs coming in and out. That’s when I went down and followed him around for about a week.

And what did you see?

Well, one of the most striking things was his ability to get food to remote places in ways the Salvation Army couldn’t and other government agencies that were on the ground couldn’t. You know, the Federal Emergency Management Agency, FEMA, doesn’t deliver food. It contracts with people to deliver food.

So you have all these steps of bureaucracy you have to go through to get those contracts. And then, FEMA says you have to have a bottle of water and this and that in those boxes. There’s a lot of structure to be able to meet the rules and regulations of FEMA.

So José doesn’t really care about rules and regulations very much. So he just got his troops together and figured out where people needed food. He had this big paper map he’d carry around and lay out. And he had a Sharpie, and he’d circle villages where he’d heard people needed food or where a bridge was out.

And then he would dispatch people to get the food there. Now, how are you going to do that? He was staying in a hotel where some National Guard and military police were staying to go patrol areas to make sure they were safe. He would tuck his big aluminum pans of food into the back of those guys’ cars, and say, Could you stop and drop these off at this church?

During that time in Puerto Rico, he funded a lot of it off of his own credit cards or with cash. And then he’s on the phone with people like the president of Goya or his golf buddies who are well-connected, saying, hey, we need some money. Can you send some money for this? Can you send some money for that?

So he just developed this network, almost overnight. I mean, he is very much a general in the field. He wears this Orvis fishing vest, has cigars in one pocket, money in the other. And he just sets out to feed people.

And there were deliveries that were as simple as he and a couple of folks taking plastic bags with food and wading through a flooded parking lot to an apartment building where an older person had been stuck for a few days and couldn’t get out, to driving up to a community that had been cut off. There was a church that was trying to distribute food.

We drive through this little mountain road and get to this church. We start unloading the food, and the congregation is inside the church. José comes in, and the pastor thanks him so much. And the 20 people or so who are there gather around José, and they begin praying.

And he puts his head down. He’s a Catholic. He’s a man who prays. He puts his head down. He’s in the middle of these folks, and he starts to pray with them. And then, pulls out his map, circles another spot, and the group is off to the next place.

And when Russia invades Ukraine, he immediately decided it was time for World Central Kitchen to step into a war zone. You know, so many people needed to eat. So many Ukrainians were crossing the border into Poland.

There are refugees in several countries surrounding Ukraine. So a lot of the work that they did was feeding the refugees. They set up big operations around train stations, places where refugees were coming, and then they were able to get into cities.

One of their operations did get hit with some armaments early on. Nobody was hurt badly. But I think that was the first time that they realized this was an actually more dangerous situation than perhaps going in after there’s been an earthquake.

But the other thing that really made a difference here is, José Andrés and World Central Kitchen would broadcast on social media, live from the kitchens. In the beginning, he’d be holding up his phone and saying, we put out 3 million meals for the people of Puerto Rico, chefs for Puerto Rico. It was very infectious.

And now, one of the standard operating procedures for people who are in the World Central Kitchens is to hold up the phone like that — you can see the kitchen, busy in the back — and talk about how many meals they’ve served. They have these kind of wild meal counts, which one presumes are pretty accurate. But they’re like, we served 320,000 meals this morning to the people of Lviv.

I mean, that scale seems important to note. This is not the kind of work that feeds a few people and a few towns. When you’re talking about 300,000 meals in a morning, you’re talking about something that begins, it would seem, to rival the scope and the reach of the groups that we tend to think of as the most important in the disaster-relief world.

Absolutely. And the meals — there are lots and lots and lots of meals. But also, World Central Kitchen hires local cooks. They’ll hire food truck operators, who obviously have no work, and pay them to go out and deliver the meals. They’ll pay local cooks to come in and cook. That’s what they do with a lot of their donations, which is very different than other aid organizations. And this then helps the local economy. He’s trying to buy as much local food as he can. That keeps the economy going in the time of a disaster. So that’s a piece of his operation that is a little different than traditional aid operations.

So walk us up to October 7, when Hamas attacked Israel. What does Chef José Andrés and the World Kitchen do?

Well, he had had such impact in Ukraine. And I think the organization itself thought that they had the infrastructure to now take food into another war zone. Gaza, of course, was nothing like Ukraine. But World Central Kitchen shows up. They’re nimble. They start to connect with local chefs.