MBA Knowledge Base

Business • Management • Technology

Home » Management Case Studies » Case Study of Cisco: Transformation of Entire Supply Chain into an Extended Enterprise System

Case Study of Cisco: Transformation of Entire Supply Chain into an Extended Enterprise System

Cisco Systems of San Jose, California, is a company that develops networking devices such as switches, routers, network management software, and dial- up access servers. By the mid 1990s, realizing that growth depended on our ability to scale manufacturing, distribution and other supply chain processes quickly, Cisco managers decided to reinvent its business model and turn itself into a Web-enabled company . An ‘ecosystem’ which in fact transformed the entire supply chain into an extended enterprise system based on internet technology was created in order to links customers, prospects, partners, suppliers and employees in a multi-party, multi-location electronic network.

E-Business can be defined as all electronically mediated information exchanges, both within an organisation and with external stakeholders supporting the range of business processes. It links internal employees with external customers, suppliers through technology like Internet, intranets, and extranets. E-commerce, conceived as a subset of e-business, can be categorized as buy-side e-commerce which are equivalent to upstream supply chain and sell-side e-commerce which equate to downstream supply chain. A ‘supply chain’ is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished products, and the distribution of these finished products to customers. An effective supply chain management can improve efficiency throughout e-business.

Cisco estimated that in financial year 2000, a total of US$695 million would be saved by adopting this interconnected supply chain. These solid figures prove the potential benefits e-business can bring into Cisco are enormous. Broadly speaking, it is argued that there are at least two primary ways in which the application of e-business technologies can improve the efficiency of a supply chain. First is known as disintermediation, which organisation eliminates the communication and coordination costs associated by eliminating links in the supply chain. The second way is by lowering the cost of communication and coordination among the various members of supply chain. In this case, Cisco adopted the second way by using information technology to communicate, which enable faster, more accurate, and lower cost information exchanges with its trading partners.

Upstream Issues (Buy-Side)

Upstream supply chain is the transactions between an organisation and its suppliers and intermediaries. In this particular case, Cisco outsourced most of the manufacturing and logistics activities as James Crowther, customer business solutions manager said, in order to increase production capacity enough to meet demand. Outsourcing is a business activity subcontracting a process, product design or manufacturing, to a third-party company. Cisco’s suppliers not only make all of the components and perform 90 per cent of the sub-assembly work, but they also undertake 55 per cent of the final. By outsourcing production of 70 percent of its products, Cisco has quadrupled output without building new plants. Furthermore, through Cisco Manufacturing On-line, Cisco has created an extranet application that increases productivity and efficiency in the manufacturing, supply, and logistics functions among globally networked partners. The accomplishment not only increased the outputs but left Cisco free to concentrate on their real strengths: new product development , looking after customer needs and brand management .

Cisco Manufacturing Connection Online (MCO)

Since relationships with suppliers are especially critical in the E-conomy, Cisco has created an Extract application that leverages productivity and efficiency in the supply function through MCO, which can be viewed as supply chain portal that seamlessly connects Cisco to its contract manufacturers, distributors, and logistics partners. The core of MCO dealing with their supplier is centralizing the process control and as a consequence decentralizing actual execution. There is a three-part strategy to scale its upstream supply chain in a cost-effective manner in MCO:

- Auto test. To resolve the testing problem, Cisco has installed automated test cells on all Cisco-dedicated supplier production lines using Cisco-developed technology to automatically configure test procedures for each specific customer order so that the quality could be controlled and the cost of deploying a test engineer could be saved. However, although Cisco outsourced much of the physical test, the company retained the intelligence behind the testing.

- Direct Fulfillment. Cisco launched a global direct fulfillment model under which most of the company’s manufacturing partners can now ship directly to customers. This will reduced the distribution cost between Cisco and supply chain partners.

- Dynamic replenishment. By direct linking to the suppliers, Cisco could gain real-time access to supplier information so that delivery lead-times, errors and inventory will be cut and the productivity of its employees involved in purchasing will be improved. The purchasing teams can focus on more strategic activities such as partnership and business development.

The implication of increasing outsourcing of core activities is that companies will move towards the virtual organisation which leads to a more responsive and flexible company with great market orientation. As Pete Rukavina, Cisco’s director of global supply chain management, addressed: “For every Cisco manufacturing employee there are six virtual manufacturing employees who use Cisco processes, are measured against Cisco metrics, and are located around the world.”

Traditionally, a new product introduction had been a process in which engineering, procurement, manufacturing and marketing were performed sequentially in time-consuming steps. Cisco has networked these functions in order to extract real benefits with its partners. A perfect example could be car industry where car plants traditionally would be located nearby the raw material factory so that inputs directly from factory will be produced as a result of cars. However, there has been a trend to outsourcing more and more components such as lights, trim and even engine to third party. Just-in-time of Toyota was created base on the outsourcing strategy.

Downstream Issues (Sell-Side)

Downstream supply chain is the transactions between an organisation and its customers and intermediaries. There were some potential issues which Cisco has faced in the process of selling products in the past:

- One-third of all faxed orders. Due to the nature of fax, orders will inevitable contain errors sometimes so that it will delay the processing. In addition, 15 per cent of the number of orders required reworking.

- Sundry expenses. Delivering software purchases to its customers on CD by a freight forwarder will generate a cost of delivering.

- New product introduction. Time-to-market of new products is counted in months or years.

Cisco Connection Online is introduced in order to deal with these issues.

Cisco Connection Online (CCO)

Customer Connection Online is essentially a web portal to information stored in Cisco’s enterprise resource planning [ERP] databases, legacy systems and client/server systems, and acts as a comprehensive resource for our customers, resellers, suppliers and partners. In fact, it used the Internet as the prime customer contact channel so that customer information and decision-making feeds directly into the supply chain. Technology is vital to supply chain management since managing relationships with customers, suppliers and intermediaries is based on the flow of information and the transactions between the parties. Customers rely on CCO to answer questions, diagnose net work problems, and provide solutions and expert assistance worldwide based on four components of CCO:

- Market-place. It is a virtual shopping center in which customers can purchase items online. It also offers users tools for configure, price, route and submit orders. This function can be used to solved the first problem mentioned above which is lots of errors contained in fax. With the introduction of Market-place, customers rarely make purchasing mistakes by ordering online. Only 2 percentages are required rework.

- Status Agent. It gives Cisco’s sales force, as well as direct customers and sales partners, immediate access to critical information about the status of customers’ order. The sales force can not only prevent possible billing or shipment problems by accessing order information but also save time such as tracking order status in order to devote to building relationships with customers and seeking new business opportunities.

- Customer Service. It provides nontechnical assistance on a self-help basis for customer requests. No one is better motivated to help the customer than the customers themselves. The self-service model which Cisco is committed is argued to know as raising the customer satisfactory overall.

- Technical Assistance and Software Library. It enables customers and business partners to get online answers to technical questions and download software updates and utilities for Cisco hardware, which saved over US$500,000 per year in freight forwarding charges.

Specifically, the Web gives Cisco both a vehicle through which customers can find out about products and buy them and an automated support system that can reach a larger audience. Modern marketing philosophy requires that organisation be committed to customer orientation. It is important that introduce a new product earlier than competitors because customers intend to accept the first new item. In the response of the third problem identified above, Cisco automated the process for gathering product data information, thereby reducing the amount of time required to less than 15 minutes. It is believed that this type of positive impact on time-to-market generated an extra US$388 million in income during 2000.

Furthermore, it is recognized that building strong customer relationships is the key driver to sustainable profitability. CRM is therefore considered to be the most important element within e-business context. Essentially, CRM is an approach to building and sustaining long-term business with customers. It is about customer acquisition, customer retention and customer extension. It is recommended that the first step is to retain existing customer because the costs of acquiring new customers are so high that repeat business is essential. The next step is to acquire new customers on a profitable basis. It is argued that by giving customers tools for self-configuration and turning its back office into the customer’s front office could be one of the best ways Cisco do.

Cisco Employee Connection (CEC)

Cisco’s ecosystem looks inward as well as outward. Whereas CCO addresses the needs of Cisco customers, partners, suppliers, and employees, Cisco Employee Connection (CEC) is limited to information and services that address the unique needs of individual Cisco employees. In order to improve employee satisfaction and scale its workforce without incurring unnecessary overhead, Cisco re-engineered all its internal and external employee services. Applying the CEC, the following benefits can be provided.

- Ubiquitous communications. Every one of Cisco’s employees around the world is connected through the Cisco network.

- Streamlined business. The interactive tools reduce the time that employees spend handling repetitive tasks and streamline routine business process.

- Integrated business systems. The CEC home page serves as the launching pad, all of information sharing the same navigational tools and a common user interface.

E-Supply Chain (Both Upstream and Downstream Issue)

In today’s digital economy, flexibility, adaptation and responsiveness are critical to success. The Internet is the greatest ICT (information and communication technology) tool, and ‘integration’ is the key to efficiency and success. The company Cisco has opened up its internal information systems to suppliers and other supply chain partners, giving the employees the same access rights to information as Cisco employees, and as a result enabling the Cisco ecosystem to act as a distributed knowledge management network. This networked ecosystem that leverages the collective capabilities of all supply chain partners integrates all supply chain activities so that it achieved successful e-supply chain management. The reasons for that can be described as:

- Firstly the ecosystem standardizes and streamlines internal processes. The successful ERP system associated with CEC implementation forces Cisco to standardize, restructure and streamline the ‘internal’ functions. ERP systems enable organisational standardization, including the standardization among different locations belonging to the same enterprise.

- Secondly, the ecosystem streamlines external processes by seamless integration with suppliers and customers in terms of MCO and CCO. Materials and inventory position, product availability, price information, purchase orders and changes, vendor receipt/acceptance, Invoice payments and status reporting information are all visible among partners, including design-related information and sales forecasts

- Thirdly, Cisco has formed strategic alliances and long-term partnerships with suppliers and customers, basing on mutual trust and win-win strategy. Lack of mutual trust and unwillingness to share information among the partners appear to be the greatest obstacles in the way of e-collaboration.

Comparing the Cisco ecosystem with SIMON (Shell Inventory Managed Order Network) which applied by Shell Chemicals, SIMON enables the transfer of responsibility for inventory management from customer to supplier. In other words, there is no need for customer to place an offer since vital inventory will be on customer. Customers pay only for what they consume. The SIMON is so successful in the downstream process that it was then applied to the upstream processes which are acquiring raw materials from supplier. Both Ecosystem and SIMON works in some extent due to the mutual trust and a belief that there are significant benefits to be realized on both side. The shared information between all parties in the supply chain is also critical to succeed. However, e-business does not always lead to organisation success. For instance, Webvan, a top internet grocer based in the US, went bankrupt in 2001, because of poorly implemented e-business and over depending on technology and missed out the customers and inter-organisation management.

To sum up, the ability to engage in collaborative planning and making joint decisions with both suppliers and customers are critical components of forming e-supply chain. Moreover, lack of integration between members of a supply chain results in operational inefficiencies that compromise the performance of the supply chain .

Related Posts:

- Case Study: Zara's Supply Chain Success Story

- Case Study: How Walmart Enhances Supply Chain Management with ERP Initiatives?

- Case Study of Global Knowledge: Technology as an Effective Ingredient of Customer Relationship Management (CRM)

- What is 4G?

- Information Systems in Various Levels of Modern Organizations

- Case Study: Cisco "Self-Defending Network" Ad Campaign

- Case Study on Information Systems: Cisco Systems

- Case Study: Success Story of Pfizer Inc

- E-Commerce - Definition, History and Types

- Architecture and Key Characteristics of Cloud Computing

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

How Cisco transformed its supply chain

The Cisco supply chain is highly diverse, extensive, and global. With more than 300 product families, Cisco has a wide range of gear targeted at a spectrum of customers with vastly different expectations and fulfillment requirements.

Most Cisco products use a configure-to-order (CTO) production model. Products are built based on confirmed customer orders. A large percentage of Cisco growth comes through acquisitions, and they bring their own supply chain requirements and processes that need to be integrated into Cisco core operations.

Like many large enterprises in today’s fiercely competitive climate, Cisco looked toward optimizing its supply chain to increase business scale and agility. Throughout the planning and execution, supply chain stakeholders and Cisco IT kept a laser focus on business requirements and the capabilities needed to support them.

It simplified and consolidated supply chain business processes and its ERP system, and created a standardized, automated, end-to-end workflow. Today, 85 percent of the US$43 billion Cisco revenue is captured on the new platform. The transformation has enabled:

● Nimble expansion into new and emerging markets

● Shorter time to market for new products and offers

● Rapid acquisition integration

● Freight savings

● Intelligent scheduling

● Improved customer and partner experience.

Jun Kim, APJC Supply Chain and Manufacturing Operations VP at Cisco will attend Manufacturing Supply Chain Officer Summit as a keynote speaker and share how Cisco is harnessing the power of digitization. The summit will be staged in Singapore on 08 June 2017.

Find further information at: http://manufacturing.sco-summit.com/2017/index.php

- Elevate Your Sustainability Transparency Sustainability

- Peter Sharoff Procurement Specialist: P&SC LIVE New York Technology

- Apty: Why Data is Vital to Supply Chain Management Technology

- Michelin: Increasing Agility Using AI Simulation Technology Technology

Featured Articles

The Categories – Part 3: Procurement & Supply Chain Awards

Mark your calendars for the debut of The Global Procurement & Supply Chain Awards 2024 at Procurement & Supply Chain LIVE London on 24 September 2024 …

Meet our Sponsors: Procurement & Supply Chain LIVE New York

ProcessUnity, ServiceNow, and Beroe are sponsoring Procurement & Supply Chain LIVE New York, due to take place on 5-6 June 2024 …

The Categories – Part 2: Procurement & Supply Chain Awards

Discover the awards that your company, executive or project could be honoured with at The Global Procurement & Supply Chain Awards 2024 …

Top 100 Women 2024: Sheri Hinish, EY – No. 3

Top 100 Women 2024: Gretchen McCarthy, Target – No.2

Procurement & Supply Chain Awards: The Categories (Part 1)

- Top 100 Women 2024: Jacqui Rock, NHS England – No.1

- Supply Chain Lessons to Learn from Baltimore Bridge Collapse

- P&O Ferries: Sailing into the Future Alongside Netcompany

- PwC Examines Digital Trends in Operations for 2024

- P&SC LIVE New York 2024 Virutal - SAVE THE DATE

Get full access to Cisco Systems, Inc.: Supply Chain Risk Management and 60K+ other titles, with a free 10-day trial of O'Reilly.

There are also live events, courses curated by job role, and more.

Cisco Systems, Inc.: Supply Chain Risk Management

Read it now on the O’Reilly learning platform with a 10-day free trial.

O’Reilly members get unlimited access to books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.

Book description

This new case study examines how leading network technology provider Cisco responded to a tsunami in Japan that could have disrupted delivery from 250 key "Tier 1" suppliers. In addition to natural disasters, it shows how Cisco manages lean supply chain risks associated with political upheavals, regulatory mandates, economic uncertainty, rapid technological and customer change, capacity constraints, globalization, and more. Focusing on realistic issues and challenges throughout, it offers exceptional value to both students and practitioners. Authors: Maria Jesus Saenz, MIT-Zaragoza International Logistics Program; Elena Revilla, IE Business School.

Table of contents

- About This eBook

- Copyright Page

- The Company

Product information

- Title: Cisco Systems, Inc.: Supply Chain Risk Management

- Author(s): Chuck Munson

- Release date: September 2013

- Publisher(s): Pearson

- ISBN: 9780133757736

You might also like

Global supply chain security and management.

by Darren J. Prokop

Global Supply Chain Security and Management: Appraising Programs, Preventing Crimes examines the relationship between securing a …

The Global Supply Chain and Risk Management

by Stuart Rosenberg

The heightened intensity of global competition has increased the necessity of manufacturing and distribution organizations to …

Managing Supply Chain Risk

by Sime Curkovic, Thomas Scannell, Bret Wagner

Risk management in supply chain logistics has become a necessity due to the number of variables …

Supply Chain Risk Management

by Gregory L. Schlegel, Robert J. Trent

You don’t have to outrun the bear … you just have to outrun the other guy. …

Don’t leave empty-handed

Get Mark Richards’s Software Architecture Patterns ebook to better understand how to design components—and how they should interact.

It’s yours, free.

Check it out now on O’Reilly

Dive in for free with a 10-day trial of the O’Reilly learning platform—then explore all the other resources our members count on to build skills and solve problems every day.

An Insight Into Cisco Supply Chain Strategy

Discover the strategies that have made Cisco a supply chain powerhouse and explore how DFreight can empower your own logistics operations.

In the fast-paced world of technology, where innovation and efficiency are paramount, Cisco Systems has emerged as a global leader in networking solutions. Behind their success lies a well-kept secret: a highly effective supply chain strategy. Imagine a digital freight forwarder with an online platform and mobile app that streamlines your logistics processes, enhances visibility, and boosts efficiency. That’s where DFreight comes in. If you’re looking to manage complex supply chain networks, It’s time to revolutionize your supply chain and optimize your business performance.

In this blog post, we will delve into the inner workings of Cisco supply chain strategy and uncover the key elements that have propelled them to the forefront of the industry.

Table of Contents

Cisco’s Supply Chain Framework

At the core of Cisco’s remarkable supply chain success lies a robust framework that forms the foundation of its operations.

This framework comprises key components that enable Cisco to manage its supply chain and meet customer demands effectively. Central to their approach is the emphasis on collaboration and partnerships with suppliers and partners. By fostering strong relationships and aligning goals, Cisco ensures a seamless flow of information and materials throughout the supply chain.

Technology and automation play a pivotal role in Cisco’s supply chain framework. They leverage advanced technologies to streamline processes, enhance efficiency, and improve visibility. Automation enables Cisco to optimize its operations, reducing manual intervention and errors. By harnessing the power of data analytics , Cisco gains valuable insights into customer preferences, market trends , and demand patterns, enabling them to make informed decisions and anticipate future requirements.

Furthermore, Cisco’s supply chain framework emphasizes the importance of agility and flexibility. They understand the need to adapt quickly to changing market dynamics and customer demands. By embracing lean and agile principles, Cisco optimizes its manufacturing and distribution processes, minimizing waste and responding rapidly to fluctuations in demand.

Another critical aspect of Cisco’s supply chain framework is its commitment to sustainability and responsible practices. They strive to reduce their environmental impact by implementing green initiatives, optimizing energy consumption, and promoting the circular economy. By integrating sustainability into its supply chain, Cisco minimizes its carbon footprint and creates value for its customers and stakeholders.

Overall, Cisco’s supply chain framework embodies a holistic and collaborative approach. They have built a solid foundation that drives their supply chain excellence by focusing on partnerships, technology adoption, agility, and sustainability. This framework serves as a blueprint for other organizations seeking to enhance their supply chain strategies and achieve long-term success in the dynamic global marketplace.

Demand Planning and Forecasting

Cisco Systems excels in demand planning and forecasting, enabling them to align the Cisco supply chain with customer requirements proactively. Cisco accurately identifies demand patterns and market trends through data analytics and advanced forecasting techniques. Collaborating with customers, suppliers, and partners enhances the accuracy of their forecasts. Continuous improvement and predictive analytics further refine their demand planning, allowing them to anticipate shifts in demand and adjust the Cisco supply chain accordingly. By mastering the art of anticipating customer needs, Cisco optimizes its supply chain, enhances customer satisfaction, and maintains its industry leadership.

Efficient Procurement and Supplier Management

Cisco has achieved sourcing success through its commitment to efficient procurement and supplier management practices. Cisco’s procurement process focuses on selecting suppliers based on strict criteria, ensuring alignment with their quality standards and business objectives. Cisco fosters collaboration, innovation , and long-term partnerships by establishing strong relationships with suppliers. Supplier relationship management is critical to their strategy, allowing for effective communication, risk mitigation, and continuous improvement. Cisco’s proactive approach to procurement and supplier management ensures a reliable and streamlined supply chain, contributing to its overall success in the market.

Streamlined Manufacturing and Logistics From Factory to Customer

Cisco excels in streamlining its manufacturing and logistics processes, ensuring a seamless journey from the factory to the customer. By embracing lean and agile principles, Cisco optimizes its manufacturing operations to eliminate waste, improve efficiency, and respond quickly to customer demands. Advanced automation and technology adoption enhance production accuracy and speed while minimizing errors. In logistics, Cisco leverages optimized distribution channels, efficient transportation networks, and real-time visibility to ensure the timely delivery of products to customers worldwide. By focusing on streamlining its manufacturing and logistics, Cisco provides a smooth and reliable supply chain that meets customer expectations and drives its continued success in the market.

The Role of Technology in Cisco Supply Chain Strategy

Cisco demonstrates a strong commitment to digital transformation , leveraging technology as a critical enabler of Cisco’s supply chain success. They harness the power of cutting-edge technologies to enhance visibility, optimize operations, and drive efficiency. Through the Internet of Things (IoT) , they gain real-time insights into Cisco’s supply chain, enabling proactive decision-making and rapid response to changes.

Artificial intelligence and machine learning applications help analyze vast amounts of data, unlocking valuable patterns and trends to improve forecasting accuracy. Cisco also embraces blockchain technology to enhance traceability and transparency across the Cisco supply chain. By embracing digital transformation, Cisco ensures a robust and future-ready supply chain that can adapt to the industry’s and customers’ evolving needs.

Sustainability and Green Initiatives

Cisco is committed to sustainability and actively promotes green initiatives throughout its supply chain. Recognizing the importance of minimizing its environmental impact, Cisco sets ambitious goals for reducing carbon emissions, optimizing energy consumption, and promoting sustainable practices. They prioritize responsible sourcing, aiming to work with suppliers who adhere to ethical and sustainable standards. Cisco also embraces the circular economy, implementing recycling and waste reduction strategies. By integrating sustainability into its supply chain operations, Cisco reduces its ecological footprint and creates value for its customers and stakeholders. Their dedication to sustainability sets a positive example for the industry and reinforces their commitment to environmental stewardship.

The Future of Cisco’s Supply Chain

As an industry leader, Cisco continues to pave the way for the future of supply chain management . The company is poised to leverage emerging technologies and trends to stay ahead in an ever-evolving landscape. Predictive analytics and demand sensing will enable Cisco to accurately anticipate customer needs, ensuring proactive and efficient supply chain operations. Robotics and automation advancements will enhance productivity, reducing manual intervention and streamlining processes. Supply chain digitization and connectivity will drive real-time collaboration and data exchange, enabling end-to-end visibility and seamless integration. Cisco’s supply chain future is characterized by innovation, agility, and a commitment to continuously leveraging technology to optimize its operations and exceed customer expectations.

In the previous blogs, we looked into the supply chains of famous and leading companies, which you can read about each of them in the section below.

In conclusion, exploring Cisco’s supply chain strategy provides valuable insights into the key elements that have propelled them to the forefront of the industry. Their emphasis on collaboration, technology adoption, sustainability, and continuous improvement is a blueprint for success in managing a robust and efficient supply chain. By understanding the importance of demand planning, efficient procurement, streamlined manufacturing, embracing digital transformation, and prioritizing sustainability, businesses can learn valuable lessons from Cisco’s approach to supply chain management.

Don’t miss out on the opportunity to optimize your supply chain strategy with DFreight.

What is Cisco’s supply chain strategy?

Cisco’s supply chain strategy focuses on collaboration, technology adoption, sustainability, and continuous improvement. They prioritize efficient procurement, streamlined manufacturing, and optimized logistics to meet customer demands effectively.

How does Cisco anticipate customer needs?

Cisco employs demand planning and forecasting techniques, leveraging data analytics and market insights to anticipate customer needs accurately. By analyzing historical data, trends, and collaborating with customers, they align their supply chain to meet future requirements proactively.

What role does technology play in Cisco’s supply chain?

Technology plays a crucial role in Cisco’s supply chain, enabling enhanced visibility, automation, and efficiency. They utilize IoT for real-time insights, artificial intelligence for data analysis, and blockchain for traceability. Technology empowers Cisco to optimize operations and make informed decisions.

How can businesses manage their supply chain strategy with DFreight?

Businesses can manage their supply chain strategy effectively by utilizing DFreight’s digital freight forwarding services, which offer streamlined logistics operations through their online platform and mobile app.

Air transportation is a convenient and fast way to move cargo and is suitable for small and large companies as well as individuals. You Might Also Like

Commodities

Most Popular

Cisco Video Portal

Cisco Supply Chain National Case Competition

- Share on Facebook

- Share on LinkedIn

- Share via Email

An opportunity for university students to enhance and test their supply chain knowledge through working on a case topic to provide alternative solutions or strategies to address a current business challenge.

Share this video

Inside Outshift

Collaborations.

Search Blog

by Pallavi Kalapatapu

Published on 03/17/2023, last updated on 04/09/2024, top 10 software supply chain attacks: case studies.

Get emerging insights on emerging technology straight to your inbox.

The previous segment of the series shared a primer on supply chains, what software supply chains are, why they can lead to security breaches, and how to safeguard them. This blog post highlights the seriousness of software supply chain breaches, the extent of damage they can cause, and why you must take the matter seriously. Let's start quantifying the extent of damage caused by supply chain breaches by examining a few supply chain attack case studies.

What Percentage of Security Breaches Start with Software Supply Chain?

Determining an exact percentage is difficult, as various sources report different numbers. In recent years, software supply chain attacks have risen and posed a significant threat to organizations. According to a report by Spiceworks, in 2023, Software Supply Chain attacks will increase in severity. Another report by SD Times found that supply chain attacks impacted 64% of companies primarily due to increased OSS reliance. Many breaches use the software supply chain as an attack surface, emphasizing the importance of securing the supply chain for organizations.

Top 10 Supply Chain Attacks

In December 2020, the network management software company SolarWinds got hacked, resulting in a widespread breach of multiple government agencies and private companies. A total of 18,000 customers and businesses got impacted. The attack was traced back to a malicious software update added to SolarWinds’ Orion software, demonstrating the importance of secure software updates in the supply chain.

In 2017, Equifax's credit reporting company suffered a massive data breach that affected 147 million customers. The breach was later attributed to a vulnerability in Equifax’s website software caused by a failure to patch a known security issue. This case highlights the importance of proper patch management in the software supply chain.

In 2017, the popular system optimization tool CCleaner was compromised and used to distribute malware. The attackers were able to inject malicious code into CCleaner’s software supply chain, demonstrating the importance of secure code signing and verification processes.

Apple XCodeGhost

In 2015, hackers targeted Chinese iOS developers by compromising the XCode development tool used to create iOS apps. The attackers added malicious code to the tool, incorporated into several iOS apps on the App Store. This case highlights the importance of secure development tools and the need to thoroughly screen third-party components in the software supply chain.

2017 malware attack targeted Ukraine's government and infrastructure and spread to other countries via a supply chain attack on the software company MeDoc. It was distributed through an update to MeDoc, a tax accounting program widely used by Ukrainian companies, that released the NotPetya malware. The malware used the EternalBlue exploit.

TSMC Taiwanese chip manufacturer

In 2018, the malware was spread through the company's software update system. The virus was injected into TSMC's systems when a supplier installed infected software onto some of its machines without running an antivirus scan. The attack affected over 10,000 devices in some of TSMC’s most advanced facilities.

In November 2021, a breach was disclosed, representing a unique supply chain attack compromising data that businesses share as part of supply chain operations due to a third party's illegal access to Panasonic servers.

Indian IT services provider, the 2020 attack in which hackers used a supply chain attack to gain access to the company's network and steal sensitive client data. In this case, attackers used Wipro’s systems to launch phishing attacks against customers. Phishing exploits made Wipro a platform to attack some customers and highlight third-party risks from service providers.

The 2020 attack on the US-based software company Codecov enabled hackers to gain access to the company's software development tools and potentially steal sensitive data from its clients. The attackers exploited an error in how Codecov created docker images. This process allowed the attackers to extract a credential from the Docker image.

Dragonfly 2.0 attack

In 2014, this highly sophisticated cyber espionage campaign used compromised software updates to gain access to energy sector organizations in the US and Europe.

Numerous other supply chain attacks exist, with the log4j fiasco leading the pack. These cases demonstrate the critical importance of secure software supply chain practices and the dire real-world consequences of supply chain attacks. Let’s unpack some of these breaches and understand the source of the breach and how we can mitigate them.

Case Studies

Let's delve into some case studies of software supply chain attacks here:

The attackers could infiltrate SolarWinds' build systems and insert malware, which spread among customers as part of legitimate software updates. Due to the malicious code inserted during the build process of the software update, even though it was delivered to customers via secure signing and verification checks, since the malicious injection occurred early in the chain, signing and validating software downloads couldn't catch it either. It took almost 15 months to discover the breach.

Attackers could exploit this vulnerability because Equifax had failed to patch the affected software, even though a patch had been available for several months before the breach occurred. The attackers could then move laterally through Equifax's network and exfiltrate sensitive data belonging to approximately 147 million individuals. As a result, the primary cause of Equifax's supply chain breach was inadequately managing the security of third-party software components, combined with a failure to apply critical security patches promptly.

Diversity In Supply Chain Attacks

Though similar SolarWinds and Equifax supply chain attacks are different in several ways, just by contrasting these two, we can be mindful of the diversity in attack patterns while crafting solutions. The tabular data in Figure-2 below highlights the differences.

Attacks of this nature are just the tip of the iceberg. In addition to highlighting the different types of supply chain attacks and a broad spectrum of impacts, they emphasize the need for organizations to maintain robust security measures continuously throughout the software development and distribution processes.

Defense Strategy

Organizations must jump on software supply chain security practices to avoid similar future attacks. In addition to Implementing code signing and verification processes, conducting regular security assessments of third-party components, and implementing proper upgrade procedures enabling security practices throughout the software development life cycle. Additionally, organizations should monitor their software supply chain for signs of compromise and have incident response and remediation plans to address any security issues quickly.

Security tools that can help identify security flaws in the software components found in an organization's applications and infrastructure are a must. Mitigating attacks akin to SolarWinds using tools to continuously scan software components pre and post-deployment deployment to detect and address vulnerabilities exploited in the supply chain attack case studies.

Rescue Tools

Tools like KubeClarity could help organizations stay updated on the latest security patches and advisories for their deployed components, allowing them to take proactive steps to mitigate potential risks in supply chain attacks.

For example, KubeClarity's dashboard is a handy tool for visualizing vulnerabilities and other security risks in your software supply chain. In the example below, we see KubeClarity reporting CVEs, which is short for Common Vulnerabilities and Exposures, a list of publicly disclosed cybersecurity flaws.

While the vulnerabilities seen here in a sample application are not the exact ones that affected Equifax CVE-2017-5638 or SolarWinds CVE-2023-23836 , the report can give you an idea of how it can improve your software supply chain security by providing you visibility into potential vulnerabilities and highlighting high-severity ones that need addressing with urgency. In the subsequent blog series, we will learn more about CVEs and how to interpret them.

KubeClarity generates this list of vulnerabilities in container images and filesystems by parsing the Software Bill of Materials (SBOM) and feeding the SBOM document to specialized vulnerability scanners to generate a granular list of CVEs, as you see above. If you want to further understand SBOMs and their significance in vulnerability detection, you are on track; it is coming next.

I hope these helpful supply chain case studies got you thinking about building your defense mechanisms against becoming a supply chain attack case study.

Let's double-click on SBOMs and learn what they are and how they are pivotal in preventing supply chain attacks.

---------------------------------

Pallavi Kalapatapu is a Principal Engineer and open-source advocate in Cisco’s Emerging Technology & Incubation organization.

Unlocking Multi-Cloud Security: Panoptica's Graph-Based Approach

Discover why security teams rely on Panoptica's graph-based technology to navigate and prioritize risks across multi-cloud landscapes, enhancing accuracy and resilience in safeguarding diverse ecosystems.

Related articles

Platform Engineering for Cloud-native Applications

KubeClarity: Architecture Deep Dive

KubeClarity: Install and Test Drive

The Shift keeps you at the forefront of cloud native modern applications, application security, generative AI, quantum computing, and other groundbreaking innovations that are shaping the future of technology.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Supply Chain Management: Case of Cisco Systems

Related Papers

Abstract Cisco was among the first firms to implement a virtual close and continuous monitoring system. This case traces the development of that virtual close capability and monitoring system through technology changes, accounting process changes, changes in accounting policies, implementation of standard accounting artifacts and reorganization of the accounting and finance functions, and examines some of the resulting pay-offs. The case also examines some of the limitations of the system.

ALi Elkhateb

MIT Sloan Management Review

ManMohan S Sodhi

Studia Universitatis Babeș-Bolyai Informatica

Diana Miholca

Ciência e Tecnologia de …

Flávia Santos Twardowski Pinto

1 - INTRODUÇÃO Assim como outros grãos, o milho é constantemente exposto a possíveis contaminações fúngicas, as quais podem se iniciar ainda no campo, durante o seu desenvolvimento. Neste caso, a contaminação pode ocorrer pela presença de esporos e fragmentos de micélio ...

David J . Ulbrich

Methods Mol Biol

Duangdao Wichadakul

Shahin Mousavi Mirkalai

In this article the notion of weak mutual associativity (w.m.a.) and the necessary and sufficient condition for a (L,Γ)-associated hypersemigroup (H, ∗) derived from some family of -preordered semigroups to be a hypergroup, are given.

Martin Gabathuler

IEEE Transactions on Nuclear Science

Rolf Sundblad

RELATED PAPERS

Biological cybernetics

Jonathan Cannon

Asian Journal of Women's Studies

KIM Eunshil

International Journal of Heritage Architecture: Studies, Repairs and Maintence

Thomas Lechner

African Journal of Agricultural Research

abebe ayele

Revista Paidéi@ - Revista Científica de Educação a Distância

Ariclene Oliveira

The Journal of rheumatology

Andrei Mihai Calin

Nikolaya Velcheva

International Journal of Computer Applications

Muhammad Sarfaraz

Comparative Biochemistry and Physiology Part A: Molecular & Integrative Physiology

Peggy Rismiller

arXiv (Cornell University)

Antonio Canova

Procedia Chemistry

Lies A. Wisojodharmo

Journal of Fluid Science and Technology

Motomu Nakashima

Michel Soriano

Canadian journal of communication

Jean-Guy Rens

Canadian prosthetics & orthotics journal

Benedikt Sigurjónsson

Eurasian Soil Science

Olga Khokhlova

Hector Castellanos

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- About WDI Publishing

- Support Center

- Case Submissions

- Lost Password

Supply Chain Risk Management at Cisco: Response to H1N1

By: ravi anupindi.

Core Disciplines: International Business , Operations Management/Supply Chain

Available Documents

Click on any button below to view the available document.

If you need to make copies, you MUST purchase the corresponding number of permissions, and you must own a single copy of the product.

Electronic Downloads are available immediately after purchase. "Quantity" reflects the number of copies you intend to use. Unauthorized distribution of these files is prohibited pursuant to term of use of this website.

Teaching Note

This product does not have a teaching note.

Description

Cisco’s story will expose students to supply chain risk management (SCRM). Cisco’s simulation of a flu outbreak in Asia will leave students with a better understanding of how to utilize SCRM programs.

Teaching Objectives

After reading and discussing the material, students should:

- Understand the nature/consequences of disruptions in a supply chain.

- Appreciate the need for a supply chain risk management framework in a firm.

- Understand the key elements of a supply chain risk management system, including metrics, mitigation strategies, etc.

- Appreciate the nature of risk that a pandemic represents.

- Learn how to act based on a simulation drill framework.

- Test the robustness of the SCRM framework by considering other types of risks (e.g., Toyota-Aisin fire, hurricanes, tsunamis) and asking How would Cisco have responded?.

Related Products

Remember Me

Don't have an account? Register now!

Cisco Blogs / Manufacturing / Cisco’s Vision at Hannover Messe 2024

Manufacturing

Cisco’s vision at hannover messe 2024, sean caragata, between industrial solutions for today and a sustainable foundation for tomorrow, there’s a bridge..

As the industrial world converges at Hannover Messe 2024, Cisco is not just a participant but a catalyst for change, championing digital transformation and IT / OT collaboration to deliver business outcomes in the manufacturing, energy, and related industrial industries.

I am so excited to return to Hannover, witness the latest trends, and meet with customers and partners. Cisco demos and presentations will showcase our solutions that deliver essential business outcomes to improve uptime, revenue optimization, asset visibility, observability, cyber security, resiliency, and sustainability.

Cisco’s vision is brought to life in part through strategic relationships with leading partners we will feature in our booth, including Accenture, Deloitte, NTT Data, Orange, Rockwell Automation, Schneider Electric, WWT, and others. Together with our partners, we are pioneering solutions that redefine the boundaries of what’s possible.

Manufacturing: The Foundation of Industrial Automation and Industry 4.0

Cisco’s manufacturing practice draws from our four-decade market leadership in IT and nearly two decades of expertise and innovation in the manufacturing industry and Industrial IoT. We address key industry use cases with our range of purpose-built networking, wireless, and security Industrial IoT products that integrate with Cisco’s end-to-end enterprise networking, wireless, security, compute, observability, and collaboration platforms and services, tied together in validated designs and architectures that interoperate with the leading industrial automation systems and protocols.

At Hannover Messe 2024, we’re showcasing our latest innovations that streamline operations and secure industrial networks. Together with our partners, we will demonstrate robust integrated architectures and solutions that are driving the future of smart manufacturing in areas such as digital twin, predictive maintenance, supply chain operations, and industrial mobility. We’re demonstrating how our partnerships are leading to the development of digital solutions that solve complex industry challenges.

And we will showcase the unique capabilities of our recently completed Splunk acquisition to deliver observability, security, data analytics, and AI in manufacturing operations.

Energy: Building a Sustainable Industrial Foundation

Energy generation and industrial production are significant contributors to global greenhouse gas emissions. Cisco has created sustainable facilities solutions for manufacturing and industrial operations, building on our experience in smart and sustainable buildings, energy efficient data center and networking infrastructure, and uPOE+ switching that can deliver 90W of POE per port. We are working with Schneider Electric to deliver smart and sustainable buildings to achieve net-zero carbon and building sustainability goals, manage and reduce energy consumption, among other outcomes.

At Hannover Messe 2024, we’re presenting case studies that highlight our success in revolutionizing sustainable industrial facilities and buildings, energy management, and lower carbon emissions from industrial processes.

Sustainability: Building a Greener Tomorrow

Sustainability is a core value woven into the fabric of Cisco culture. We work with partners to enhance the capabilities of our networking solutions, allowing us to deliver powerful, energy-efficient products that drive sustainability in industrial data centers, enterprise IT environments, and OT production facilities around the world. By connecting industrial devices, machines, and systems through our intelligent networks, we provide greater asset visibility and ability monitor and manage energy consumption and other environmental metrics.

For example, we are working with Rockwell Automation on digital water solutions . Using edge sensing, wireless connectivity, and sensor technology as well as data analytics and machine learning, our solution proactively addresses water loss, significantly decreases the time required for repairs, and helps mitigate energy wasted in pumping lost water.

At Hannover Messe 2024, we will feature discussions and demos around sustainable manufacturing, supply chain, intelligent building solutions, water and wastewater management, and electric vehicle charging systems. And of course, robust industrial and IT / OT cybersecurity is foundational to all our solutions across all industries!

In our conversations with customers at Hannover Messe, Cisco will not merely present technologies; we will narrate a story of collaboration, innovation, and commitment. The partnerships we will feature are more than alliances; they are proof of the power of working together to tackle the world’s most pressing challenges.

As visitors explore our booth, they will witness how our combined efforts with these industry leaders are forging a path to a smarter, more productive, more sustainable future. Our advancements in manufacturing, energy, and sustainability are tangible, impactful, and ready to be deployed on a global scale.

We invite you join us on this journey as we build a bridge between industrial solutions for today and a sustainable foundation for tomorrow. Visit Cisco at Hannover Messe 2024 at April 22—26, 2024 | Hannover, Germany | Hall 15, Stand F18.

Director, Sales Business Development

Industrial and infrastructure group, leave a comment cancel reply.

We'd love to hear from you! Your comment(s) will appear instantly on the live site. Spam, promotional and derogatory comments will be removed and HTML formatting will not appear.

CONNECT WITH US

- Skip to content

- Skip to search

- Skip to footer

How Cisco Transformed Its Supply Chain

Available languages, download options.

- PDF (310.7 KB) View with Adobe Reader on a variety of devices

Bias-Free Language

The documentation set for this product strives to use bias-free language. For the purposes of this documentation set, bias-free is defined as language that does not imply discrimination based on age, disability, gender, racial identity, ethnic identity, sexual orientation, socioeconomic status, and intersectionality. Exceptions may be present in the documentation due to language that is hardcoded in the user interfaces of the product software, language used based on RFP documentation, or language that is used by a referenced third-party product. Learn more about how Cisco is using Inclusive Language.

Single global ERP instance, new business models, standardization, and automation throughout supply chain boost Cisco agility, resiliency, and ability to scale.

The Cisco supply chain is highly diverse, extensive, and global. With more than 300 product families, Cisco® has a wide range of gear targeted at a spectrum of customers with vastly different expectations and fulfillment requirements.

Most Cisco products use a configure-to-order (CTO) production model. Products are built based on confirmed customer orders. A large percentage of Cisco growth comes through acquisitions, and they bring their own supply chain requirements and processes that need to be integrated into Cisco core operations.

A notable exception was the Cisco acquisition of Scientific Atlanta in 2005, presently rolled under the Service Provider Video Technology Group. Scientific Atlanta set top boxes and modems are fixed-configuration products that have a cost structure and sourcing strategy different from Cisco core products. They use a build-to-stock (BTS) production model. BTS products are manufactured and held in inventory to satisfy demand as orders come in.

Until recently, Cisco maintained separate supply chain processes and an enterprise resource planning (ERP) system for its Scientific Atlanta division.

In addition to more than 1000 suppliers, along with manufacturing partners and logistics providers, the Cisco supply chain encompasses:

● 16 CTO manufacturing sites

● 4 BTS sites

● 8 strategic logistics centers

● 25,000-plus orderable product IDs, or PIDs (about 25 percent assemble-to-order, 75 percent spares)

● Millions of shipments annually (for example, approximately 9 million cartons shipped in the six months ending March 2014).

Like many large enterprises in today’s fiercely competitive climate, Cisco looked toward optimizing its supply chain to increase business scale and agility. But the company was stymied by a highly customized supply chain management (SCM) system. Disparate CTO and BTS operations, multiple ERP instances, and redundant, non-standardized processes made scalability nearly impossible, and hampered productivity and the customer experience. The complex, overly tailored Cisco version of Oracle e-Business Suite 11i included:

● More than 2500 customizations, with an estimated 50 percent of them unused

● 250 custom applications

● 30,000 custom data objects

● 19 separate databases

In this cumbersome environment, adding a single data field to an existing report required the full-time-equivalent of one employee per month. Parts data, alone, resided in seven different systems.

“IT was not able to respond quickly to supply chain business requirements, and the business was not able to respond quickly to market transitions and opportunities,” says Shanthi Iyer, director, Cisco Value Chain IT, Supply Chain Management.

Transforming Business through Simplification: Large-Scale Services

Efforts to streamline the supply chain got a significant boost in early 2012 when Cisco Chief Information Officer (CIO) Rebecca Jacoby issued a directive about simplifying large-scale services (LSS), the Cisco description for foundational services that any company needs to operate such as SCM, human resources management, and customer care: The directive: Use standardized processes and common practices and customize only when necessary for flexibility. Simplifying LSS functions across the organization is critical to the ability of Cisco to scale, grow, and implement new business models competitively.

Supply chain was the first LSS to be funded, giving rise to the Supply Chain LSS Program. Earmarked for initial implementation was “LSS Bundle 1,” consisting of SCM, order management, product lifecycle management, revenue recognition, and country enablement. The Supply Chain LSS Program was guaranteed resources and budget for several quarters. Primary objectives of the supply chain transformation dovetailed (and would be driven by) three top corporate strategic priorities:

● Improve country enablement . Country enablement refers to the ability of Cisco to set up subsidiaries or branches (legal entities) in specific countries to enable the sale of products, services, and solutions at competitive prices. Upgrading to Oracle e-Business Suite R12 – specifically, exploiting out-of-the-box (OOTB) functionality such as localization – would be pivotal to advancing country enablement.

● Decommission the Cisco data center in San Jose, California . Among critical applications housed at the San Jose data center was the Oracle 11i ERP instance. This data center had no backup, and was located near an earthquake fault line. To minimize business risk, Cisco IT was migrating production applications at the San Jose data center to its data center in Richardson, Texas, where they would run on the Cisco Unified Computing System™ (Cisco UCS ® ) in a fully redundant environment.

● Integrate the Service Provider Video Technology Group (including Scientific Atlanta) . Oracle R12 functionality would enable Cisco to implement a BTS model easily, within the same supply chain system alongside CTO.

First on the LSS team’s agenda? Evaluate the feasibility of upgrading to Oracle R12, or more precisely, evaluate the feasibility of adopting R12 OOTB functionality to simplify supply chain business processes. To that end, the team’s goal was to use at least 80 percent OOTB functionality, starkly different than the highly customized Oracle 11i setup.

Transformation isn’t about installing a new system or implementing new processes. It’s about achieving business results. Throughout the planning and execution, supply chain stakeholders and Cisco IT kept a laser focus on business requirements and the capabilities needed to support them. In fact, business and IT worked side by side, physically. The two groups collocated in the same building, on the same floor specifically, for the supply chain transformation.

The business-IT alignment is bolstered by planning cycles that follow a “lead with architecture” approach. Cisco stresses the importance of aligning business and technology architectures, and uses an enterprise architecture framework that facilitates this alignment and resulting business value. The BOST reference framework and methodology from Proact Business Transformation Inc. gives IT and business stakeholders a shared taxonomy, and organizes inter-linked planning models based on four architecture views of the enterprise: Business, Operations, Systems, and Technology. Applying BOST helps ensure that the capabilities that IT delivers align with business requirements.

“BOST is very transformational in bringing business and technology architectures together,” says Raman Prabhakaran, manager, Cisco IT. “For the transformation, we needed to understand business processes, such as delivery and shipping, and how they transfer to the supply chain. We need to provide data to business stakeholders and discuss operational challenges. BOST helps us get there faster.”

Laying the Groundwork: Global Process Design

For each major area of the end-to-end supply chain (from demand and supply planning to scheduling, managing order backlogs, communicating with partners, and delivering products to customers), the LSS Program team assessed Oracle R12 OOTB functionality against existing outsourced manufacturing and logistics processes. The team focused on:

● What is currently being done: What are the business requirements? Must haves? Unique operational aspects?

● What Oracle R12 OOTB functionality is available: What would the end process look like? Could it be used to run the business without customization?

● Where the business needs to go: What are the next-generation capabilities required for Cisco to be successful?

After three months, the team had crafted a set of business processes that described, at a high level, the scope of the program, how the transformation would look, and the changes that would be required to run the business using at least 80 percent Oracle R12 OOTB functionality.

Following the end-to-end process mapping, the team identified about 60 essential design decision scenarios. For example, at what point in the process flow should a purchase order (PO) be created in Oracle? After all the answers were logged, the team reduced the design decisions to 12 that were considered foundational.

“Going through the questions and answers not only informed the design, but gave us direction on how the process would look and what needed to be transformed,” says Joe McMorrow, director, Supply Chain Transformation, Global Business Operations at Cisco. “We also matched business requirements to potential IT activity.”

Using information culled in the design phase, program leads produced a visual called the “circle of light.” It represented the entire supply chain process, starting with forecasting. Stars marked milestones in the process, and callouts along the circle corresponded to the 12 foundational design decisions.

“The circle of light represented what the transformation would look like and identified areas that had change impacts to the business,” says McMorrow. “We used this one-page visual to help socialize the program with senior management. It gave them an opportunity to digest, in a quick way, what it would mean to transform from Oracle 11i in-house manufacturing to R12 OOTB functionality and outsourced manufacturing.”

Decommissioning the San Jose Data Center

Housing critical supply chain systems and ERP in the San Jose data center put Cisco at risk. The site has no backup and is located near an earthquake fault. Cisco IT transitioned all ERP and non-ERP supply chain processes and systems from the San Jose production data center to the Richardson, Texas, data center. In January 2014, Oracle 11i in the Cisco San Jose data center was fully decommissioned. The move to the Richardson data center, one in a pair of active-active data centers, closes a critical gap in business resiliency that existed in San Jose. The paired data centers run critical applications in both places simultaneously. In case of a disaster at one site, the other can protect the uptime and availability of data.

In the Richardson data center, Oracle R12 operates entirely on the Cisco UCS platform. Cisco UCS combines computing, networking, storage access, and virtualization in a single system. The move to Oracle R12 on Cisco UCS, along with integrating business-to-business and BTS models on the same SCM system, has greatly reduced infrastructure and process complexiity. Onboarding new manufacturing partners and nodes is faster, 6 months versus 18 months, and engineering change order (ECO) communication is more efficient.

As part of the Richardson data center cutover, the release team tested 10 regression scenarios that included backlog management and all key downstream steps in the order fulfillment process. No issues arose during the business verification testing. More than 14,000 ship sets moved through the system in the first week and a half without any major incidents. Cisco IT has turned its focus on delivering and validating R12 reports required for fiscal quarter-end reporting and U.S. Sarbanes-Oxley Act (SOX) records storage compliance.

Enabling New Business Capabilities

During the transformation, the supply chain ERP underwent significant consolidation (Table 1). Cisco IT also simplified and consolidated hundreds of reports, and transformed or lifted and shifted more than 300 business capabilities and applications.

Table 1. Cisco Supply Chain ERP: Before and After Transformation

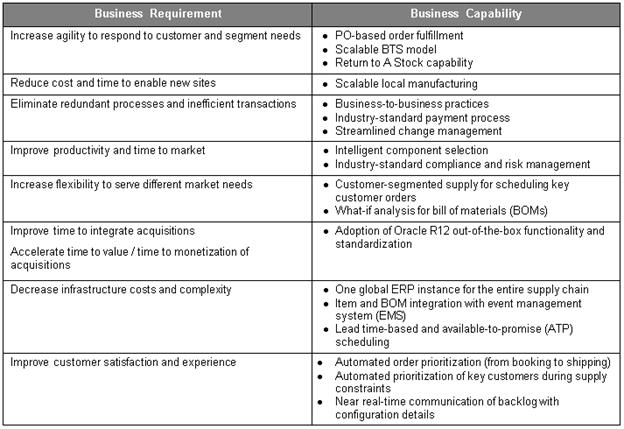

Working with business stakeholders, Cisco IT re-engineered and automated several processes and new capabilities throughout the supply chain. All the IT-enabled capabilities aligned with identified business requirements (Table 2). These efforts, coupled with the consolidation to a single global ERP instance, have yielded a host of supply chain process improvements, including:

Order fulfillment:

● Reduced response time latency of request and order statusing

● Automated prioritization of designated customers during supply constraints

● Reduced order fulfillment time from 11 days to 3 days using the BTS model

● POs processed in minutes instead of hours

● Faster change management (due to eliminating multiiple systems)

Scheduling and returns:

● Customer-segmented supply used for scheduling customer orders

● Near real-time communication of backlog with configuration details

● Parallel fulfillment of low-margin products through BTS supply chain

● Improved returns handling with Return to A Stock capability

Table 2. IT-Enabled Capabilities Align with Business Requirements

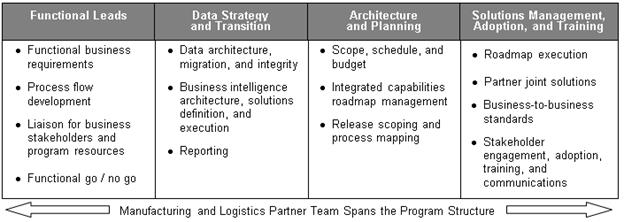

Structuring the Supply Chain LSS Program

The Supply Chain LSS Program team is composed of Cisco IT and business stakeholders and subject-matter experts throughout the supply chain organization. Table 3 shows the program team structure and responsibilities.

Governance and assigned roles provide focused oversight. The executive steering committee sets the strategic direction, reviews and approves the portfolio roadmap, and manages resources. The operating committee maintains the consolidated roadmap, escalates funding recommendations, and develops operational scenarios. For example, to ensure thorough evaluation of derived business value from the business unit and executive perspectives, key design decisions (the level of R12 customization required, associated risks, etc.) were created and vetted by both the LSS Program team and operating committee members at the executive level. The program management office maintains planned-versus-actual results, governs projects, and resolves issues.

Table 3. Supply Chain LSS Program Team Structure and Responsibilities

Training Stakeholders

The training team uses several communication methods to prepare the organization for each set of releases and their corresponding functionality. Different training methods are used based on the audience and purpose:

● Instructor-led training for reaching a wide audience; used for communicating complex process changes.

● Web-based training for large, regionally dispersed groups; used for content not likely to change and situations with additional development time.

● Handy, short reference guides used for describing low-impact, system-specific changes. Guides were available online in a centralized location.

● Video-on-demand recordings of instructor-led sessions or SME training; good for users who could not attend live sessions and training refreshes.

Predominantly using 95 percent Oracle R12 OOTB functionality, Cisco simplified and consolidated supply chain business processes and the ERP system, and created a standardized, automated, end-to-end workflow. Today, 85 percent of the US$43 billion Cisco revenue is captured on the new platform.

Chief among the business benefits resulting from the supply chain transformation:

● Time to add a new node (factory) shrunk from 18 months to 6 months.

● 30 to 50 percent reduction in time to market

● Up to 73 percent reduction in order cycle times

● Approximately 25 percent reduction in manual product touches

● Increased profitability from 12 percent target reduction in cost-to-serve ratio

● 30 to 50 percent reduction in support costs

What’s more, the transformation has enabled:

● Nimble expansion into new and emerging markets: Rapidly set up legal entities in emerging markets; end-to-end business capabilities and processes; common global capabilities for country-specific needs; local regulations and practices compliance.

● Shorter time to market for new products and offers: flexibility in offer structures, commerce model, sourcing and delivery options; ability to handle whole offers.

● Rapid acquisition integration: Flexibility to leverage BTS or CTO production models.

● Business-to-business model with Cisco manufacturing partners: Eliminates redundant transactions; simplifies fulfillment processes and infrastructure.

● Freight savings: Flexibility to ship direct from a manufacturing site or from a manufacturer direct to customer’s distribution center.

● Intelligent scheduling: Ability to see the material availability at a detailed assembly level across the whole supply network.

● Improved customer and partner experience: For customers - visibility of status throughout the order cycles; better lead times due to node reductions; shorter time to delivery; better synchronization of demand and supply; order and invoice accuracy. For partners - smooth integration through Cisco Commerce Workspace (CCW) and supply chain connectivity; improved collaboration; product lifecycle management (PLM) services with flexible deployment options.

Lessons Learned

Cisco offers the following best practices for organizations embarking on a supply chain transformation.

● Secure executive focus and commitment up front.

● Socialize business benefits, change impacts, and risks with senior management clearly and early.

● Engage executives for timely mitigation of program issues and risks.

● Seek cross-organizational sponsorshop to help overcome roadmap hurdles and customer concerns.

● Ensure business and IT alignment across all program tracks. Encourage well-informed, timely decisions and resolutions made together.

● Reduce employee burnout by establishing a dedicated program team. Leverage subject-matter experts from functional groups as needed.

● Manage stakeholder engagement at a functional level.

● Nurture a strong partnership with suppliers and manufacturing and logistics partners.

● Encourage well-informed, timely decisions and resolutions.

● Ensure you have support of senior management, internal project teams and leads, implementation partners, and vendors. Keep the lines of communication open.

● Use collaboration technology, such as synchronous and asynchronous video, with supply chain partners for quicker, more cost-effective decision-making.

The last node in Cisco’s supply chain went live in the fourth calendar quarter of 2013. Cisco IT and the LSS Program team are focused on the following:

● Stabilizing the R12 platform and all the new capabilities that have been implemented.

● Optimizing the platform for any additional functionality and capabilities, or enhancements to existing ones.

● Transforming other LSS processes related to the supply chain. The IT foundation between order management and the supply chain is under way, which will facilitate the buildout of fully automated entities in emerging countries.

For More Information

To read additional Cisco IT case studies on a variety of business solutions, visit Cisco on Cisco: Inside Cisco IT

This publication describes how Cisco has benefited from the deployment of its own products. Many factors may have contributed to the results and benefits described; Cisco does not guarantee comparable results elsewhere.

CISCO PROVIDES THIS PUBLICATION AS IS WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Was this Document Helpful?

A Benders decomposition approach for a new sustainable pharmaceutical supply chain network: a case study in France

- S.I. : OR for Sustainability in Supply Chain Management

- Published: 09 April 2024

Cite this article

- Fariba Goodarzian 1 ,

- Ajith Abraham 2 ,

- Jesús Muñuzuri 1 ,

- Atour Taghipour ORCID: orcid.org/0000-0003-1687-8881 3 &

- Peiman Ghasemi 4

Explore all metrics

Recently, sustainable supply chains have emerged to emphasize the importance of social and environmental concerns along with economic factors in supply chain management. In this context, there is a necessity for mathematical models that indicate environmental aspects and the social effects of the supply chain network. In the present study, a new multi-product production, distribution, and transportation, in which the economic, environmental, and social effects under CO 2 emission to fill this gap are presented. Additionally, service technology under various criteria in the social aspects and time window for the earliest and latest arrival time of products to main distribution centers are provided. Also, other novelties of this paper, the environmental effects to open main and local distribution centers, warehouses, and pharmacies are considered as environmental effects. So, the main contributions of this paper are to develop a multi objective, dynamic production and distribution planning using time windows in service technology of sustainable pharmaceutical supply Chain Network. In this regard, the mathematical model is formulated as a mixed-integer linear programming model. Moreover, a Benders decomposition approach is appropriately extended to solve the presented model. In the proposed approach, the problem is decomposed into two models of sub-problem and a master. The master problem is developed by means of preprocessing and valid inequalities. The general and relative efficiency of the model and approach is experimentally assessed. The pharmaceutical production and distribution system of France is considered as a real case study in this paper. Eventually, the results indicate that the proposed approach considerably outperforms, and the efficiency of the developed model is verified through a set of sensitivity analyses.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Aboytes-Ojeda, M., Castillo-Villar, K. K., & Roni, M. S. (2020). A decomposition approach based on meta-heuristics and exact methods for solving a two-stage stochastic biofuel hub-and-spoke network problem. Journal of Cleaner Production, 247 , 119176.

Article Google Scholar

Ahmadi, A., Mousazadeh, M., Torabi, S. A., & Pishvaee, M. S. (2018). OR applications in pharmaceutical supply chain management. Operations research applications in health care management (pp. 461–491). Springer.

Chapter Google Scholar

Aigbogun, O., Ghazali, Z., & Razali, R. (2018). Supply chain resilience and measurement dimensions: The case of halal pharmaceuticals in Malaysia. In SHS Web of Conferences (Vol. 56, p. 05001). EDP Sciences.

Alkaabneh, F., Diabat, A., & Gao, H. O. (2020). Benders decomposition for the inventory vehicle routing problem with perishable products and environmental costs. Computers & Operations Research, 113 , 104751.

Arampantzi, C., Minis, I., & Dikas, G. (2019). A strategic model for exact supply chain network design and its application to a global manufacturer. International Journal of Production Research, 57 (5), 1371–1397.

Badiezadeh, T., Saen, R. F., & Samavati, T. (2018). Assessing sustainability of supply chains by double frontier network DEA: A big data approach. Computers & Operations Research, 98 , 284–290.

Benders, J. F. (1962). Partitioning procedures for solving mixed-variables programming problems.

Chung, S. H., & Kwon, C. (2016). Integrated supply chain management for perishable products: Dynamics and oligopolistic competition perspectives with application to pharmaceuticals. International Journal of Production Economics, 179 , 117–129.

Dubey, R., Gunasekaran, A., Papadopoulos, T., Childe, S. J., Shibin, K. T., & Wamba, S. F. (2017). Sustainable supply chain management: Framework and further research directions. Journal of Cleaner Production, 142 , 1119–1130.

Fakhrzad, M. B., Goodarzian, F., & Golmohammadi, A. M. (2019). Addressing a fixed charge transportation problem with multi-route and different capacities by novel hybrid meta-heuristics. Journal of Industrial and Systems Engineering, 12 (1), 167–184.

Google Scholar

Fathollahi-Fard, A. M., Ahmadi, A., Goodarzian, F., & Cheikhrouhou, N. (2020). A bi-objective home healthcare routing and scheduling problem considering patients’ satisfaction in a fuzzy environment. Applied Soft Computing, 9 , 106385.